6/8

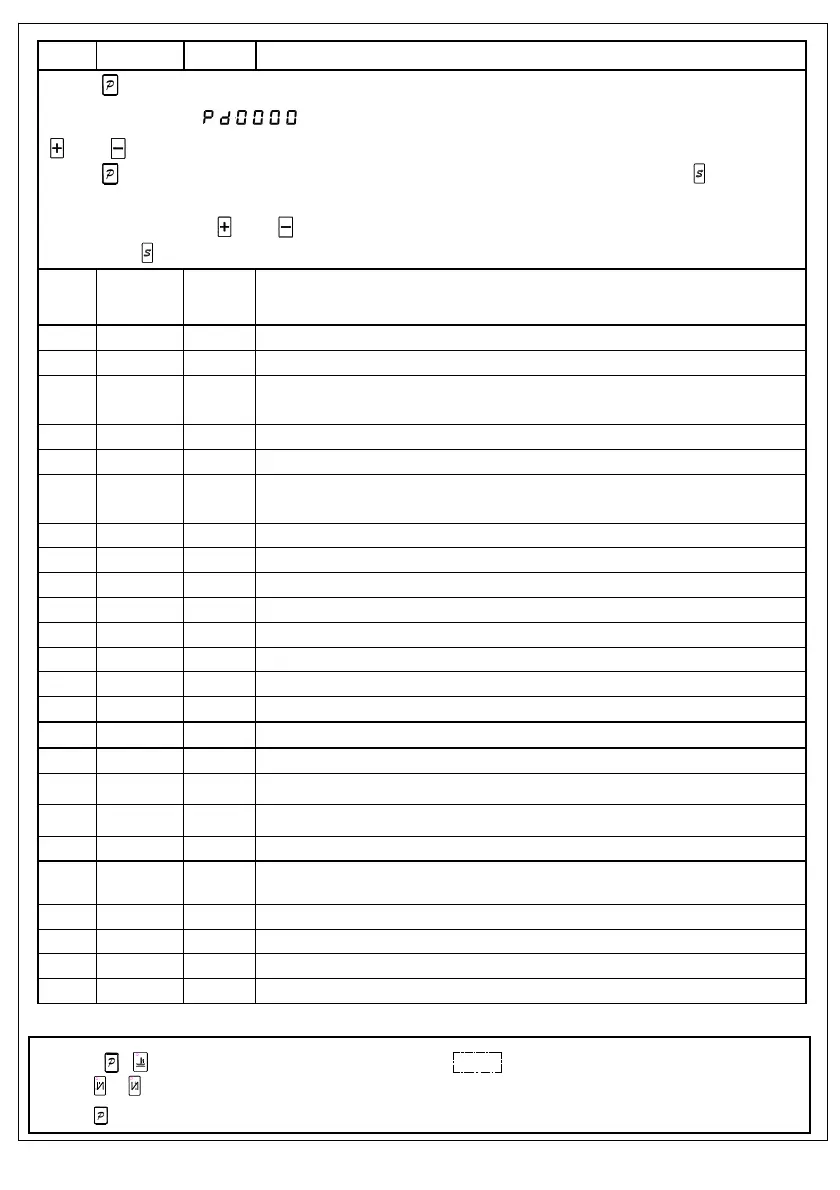

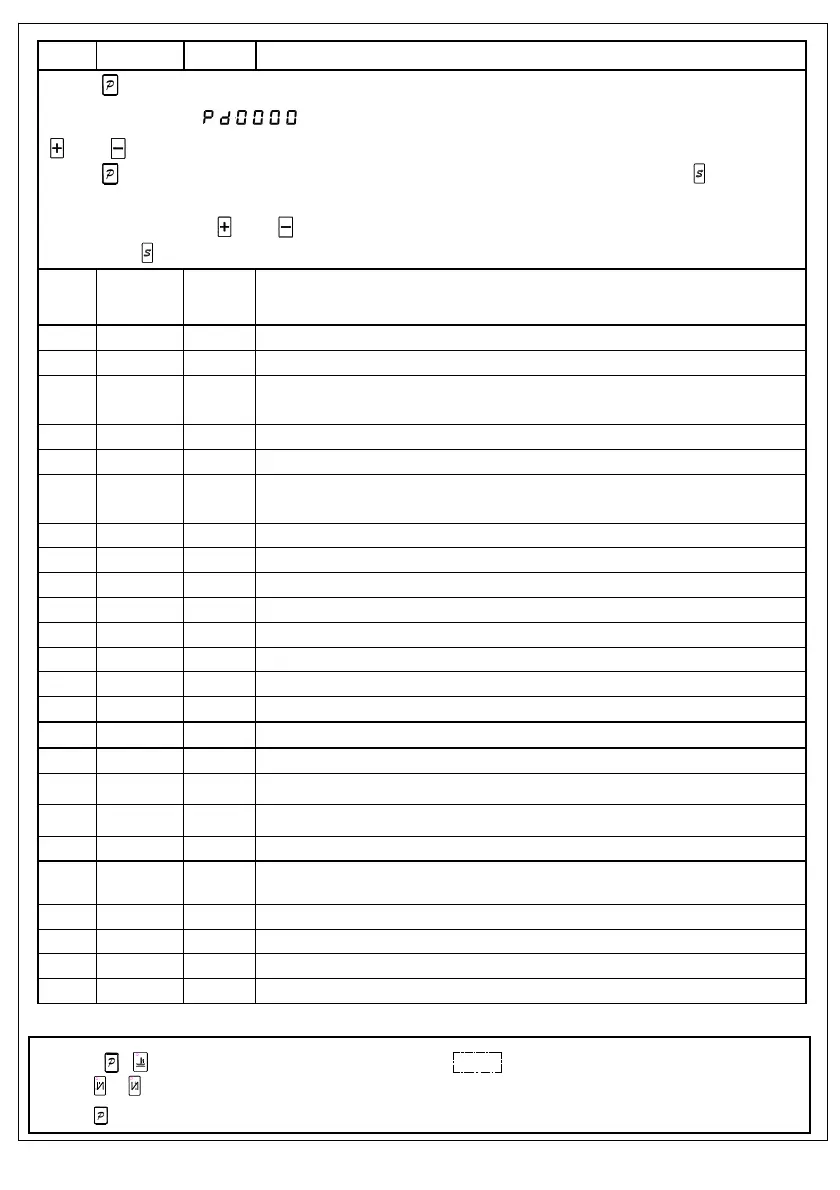

NO. Range Default Description

1、Press

P

key can modify the administrator parameter table;

2、The digital tube display

,It is required to enter password to the administrator mode. Press the corresponding

key and key to change the password value;

3、Press

P

key, If the password is correct, that is to enter the technical parameters set mode,show P2XX.Press key, the current

parameter value is displayed;

4、Press the corresponding

key and key to change the parameter value or selection parameter number;

5、At last press

key to exit parameter setting mode,return to sewing work mode.

200 0/1/2 0

Trimming mode selection:0: lockstitch machine1: interlock machine: Needle stops at the up

position and trim. 2: overlock machine: manual trimming

201 0~359 0 Mechanical angle after trimming

203 5-359 10 Trimming output start angle TS (down needle position angle as the reference point)

204 10-359 120

Trimming output end angle TE (Down needle position angle is the reference and this value

should be bigger than TS)

20A 10-60 20 Motor torque improvement coefficient during trimming

211 5-359 25 Thread release output start angle LS (down needle position angle as the reference point)

212 10-359 350

Thread release output end angle LE (Down needle position angle is the reference and this

value should be bigger than LS)

213 1-999 1 Thread release output start delay time T1 (ms)

214 1~999 10 Thread release output end delay time T2 (ms) after up needle position

215 0/1 1 Wiper function 0: disable 1: enable

216 1~999 10 Wiper output delay time (ms)

217 1~9999 70 Wiper output time (ms)

219 0/1 0 Thread clamp function 0: disable 1: enable

21A 10-359 120 Thread clamp start angle

21B 11-359 318 Thread clamp end angle

21E 11-359 160 The angle of presser foot solenoid off during thread clamping

220 200~360 360 Stop position after trimming (motor can stop with a reverse angle)

231 0/1 0 Auto test mode: 0: stitches mode 1: time mode

232 0~1000 300 Safe switch filtering time (ms)

234 0/1 0 Motor direction: 1: CCW 0: CW

240 0~9999 1000 The ratio between motor and machine (1000 stands for 1:1)

242 0~359 0 Up needle stop angle (After detecting the synchronizer signal)

243 0~359 175 Down needle stop angle

244 0~800 200 Running delay time when presser footer comes down (ms)

247 0~2000 0 The alarm time for adding oil (hours), disabled when setting 0

3.3 Monitor mode

1. Pressing

P

+ ke to enter monitor mode.The digital tube will display

2 4 0 0 0 0

.

2. Press

and key to adjust the parameter number, and the para value is shown at the same time.

3. Press

P

key then return to normal sewing mode.

Loading...

Loading...