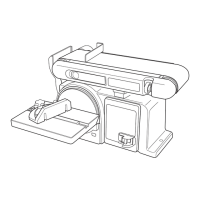

SQUARE THE TABLE

Refer to Figure 7

To ensure accurate end sanding, the work table must be

square to the sanding surfaces prior to using the work

table for disc sanding.

To check:

• Place combination square on the table with the ruler

side against the sanding disc. The table should be 90°

to the sanding disc.

• If the table is not 90° to the sanding disc, loosen the

adjustment knob and tilt table up and down until it is 90°

to the sanding disc. Tighten adjustment knob securely.

Recheck adjustment using the combination square.

Figure 7

Sanding Disc

Combination

Square

Work Table

Adjustment

Knob

SQUARE THE WORK SUPPORT

Refer to Figure 8

When using the sander belt in the horizontal position

the work support must be square to the sanding belt to

prevent the workpiece from being carried along the belt.

• Ensure the belt is tight and belt tension lever is closed.

Refer to Adjust The Drive Belt paragraph under

Maintenance.

• Place the combination square on the belt with the ruler

against the work support.

• Loosen the two hex screws securing the work support.

Adjust the work support to the square and tighten the

hex screws.

Figure 8

Combination

Square

Hex Screws

Work

Support

REPLACE THE SANDING DISC

Refer to Figure 9

• Remove the work table in reverse order of assembly.

Refer to Mount the Work Table paragraph in this

section.

• Remove Phillips head screw and locking washer

securing guard disc.

4

ASSEMBLY

• Remove the used sanding disc from the sanding disc

plate and dispose of properly

• Wipe the sanding disc plate clean.

• Peel the backing from the new sanding disc. Align the

new sanding disc with sanding disc plate and press

firmly into position. Ensure all edges are secure.

• Replace disc guard as shown, align holes and fasten

in place with Phillips head screw and locking washer.

Tighten securely.

Figure 9

4” x 36”

Sanding

Disc

Plate

Disc Guard

Phillips Head

Screw

Locking Washer

Sanding Disc

REPLACE THE SANDING BELT

Refer to Figure 10

• Use hex wrench supplied to loosen the bed locking

screw. Raise the sanding bed to 45° and tighten the bed

locking screw.

• Swing the belt tension lever open to release the belt

tension.

• Remove the used sanding belt and dispose of properly.

• Locate the directional arrow on the smooth side of the

sanding belt.

• Slide the new sanding belt over the idler pulley and

driving drum with the directional arrow pointing towards

the dust chute.

• Center the belt correctly on idler pulley and driving

drum.

• Close the tension lever to tighten the belt tension.

• Loosen the bed locking screw. Lower the bed to a

horizontal position and tighten the bed locking screw.

Figure 10

Idler Pulley

Tension Lever

Directional Arrow

Driving Drum

Bed Locking

Screw

Sanding Belt

Dust Chute

Hex Wrench

Loading...

Loading...