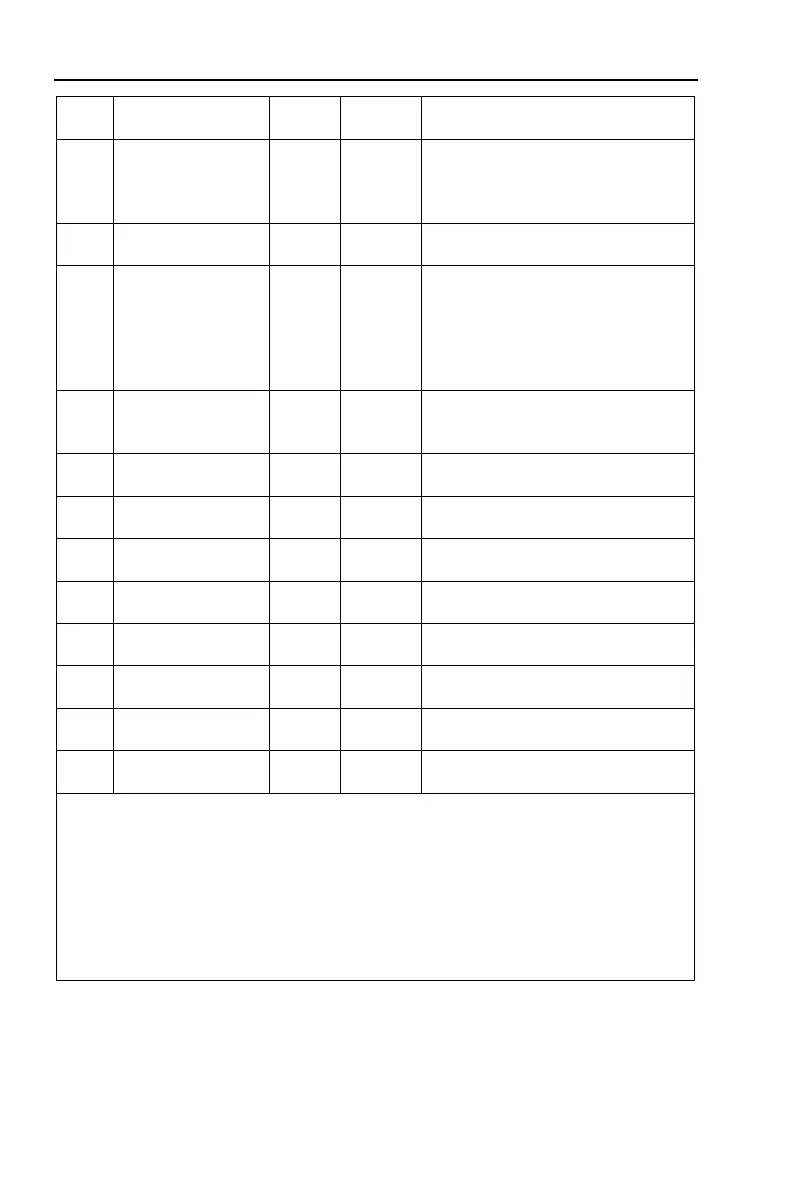

Section V Control panel and operation

16

Protection is higher than the set

value.

0 limit current; 1 voltage; 2 jump;

limit current; 3 jump + voltage; 4

current ramp; 5 double closed loop; 6

monitoring.

0 primary; 1 light load; 2 standard; 3

heavy load; 4 advanced.

0 keyboard; 1 keyboard + external

control; 2 external control; 3 external

control + communication; 4

keyboard + external control +

communication; 5 keyboard +

communication; 6 communication.

Parameter

modification

allowed

See 5.5 other setup instructions.

For MODBUS native slave address

setting.

See 5.3 programmable relay output

functions.

See 7.3.1 soft stop mode.

Nominal rated current for input

motor.

Used to set bypass time delay.

0 is prohibited, 1 is allowed.

Used to adjust the current value of

the display.

Used to adjust the display voltage

value.

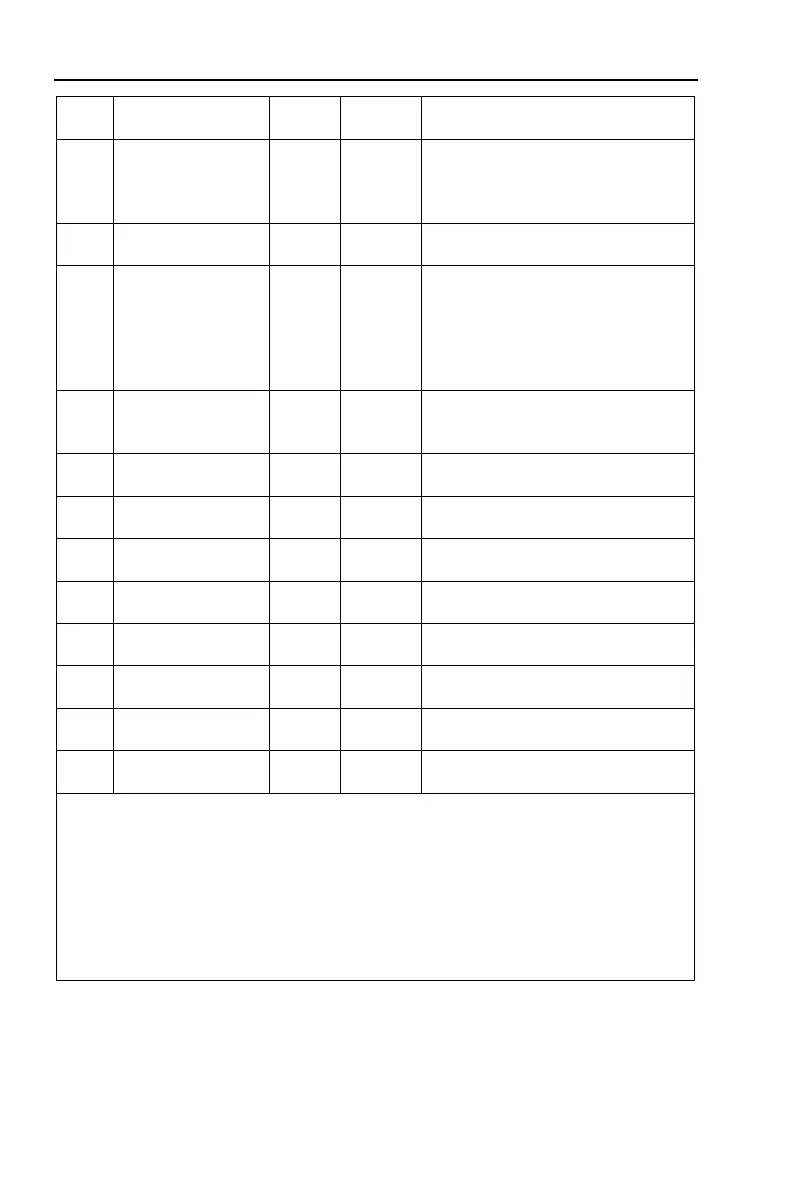

Note: 1, set the P6 load adjustment rate is calculated based on the load weight of the

motor in the number of PP based on the calculation of the maximum current, more than

this value will do the inverse time thermal protection.

2, setting the state, if more than 2 minutes without a button operation, will

automatically exit the setting state.

3, in the soft start and soft stop process can not set parameters, the other state can be set

parameters.

4, according to the confirmation key (PRG) on the power on the boot, can set

parameters to restore the factory value.

5-3 Programmable relay output functions

There are two programmable relay output function, programmable timing output

way and programmable state output way.

5-3-1. PE set from 0 to 4 items (10 ~ 14), programmable output work is timing

output way, the setting of output starting time as tabled below.

Loading...

Loading...