19

PM-1030V v5 2020-10 Copyright © 2020 Quality Machine Tools, LLC

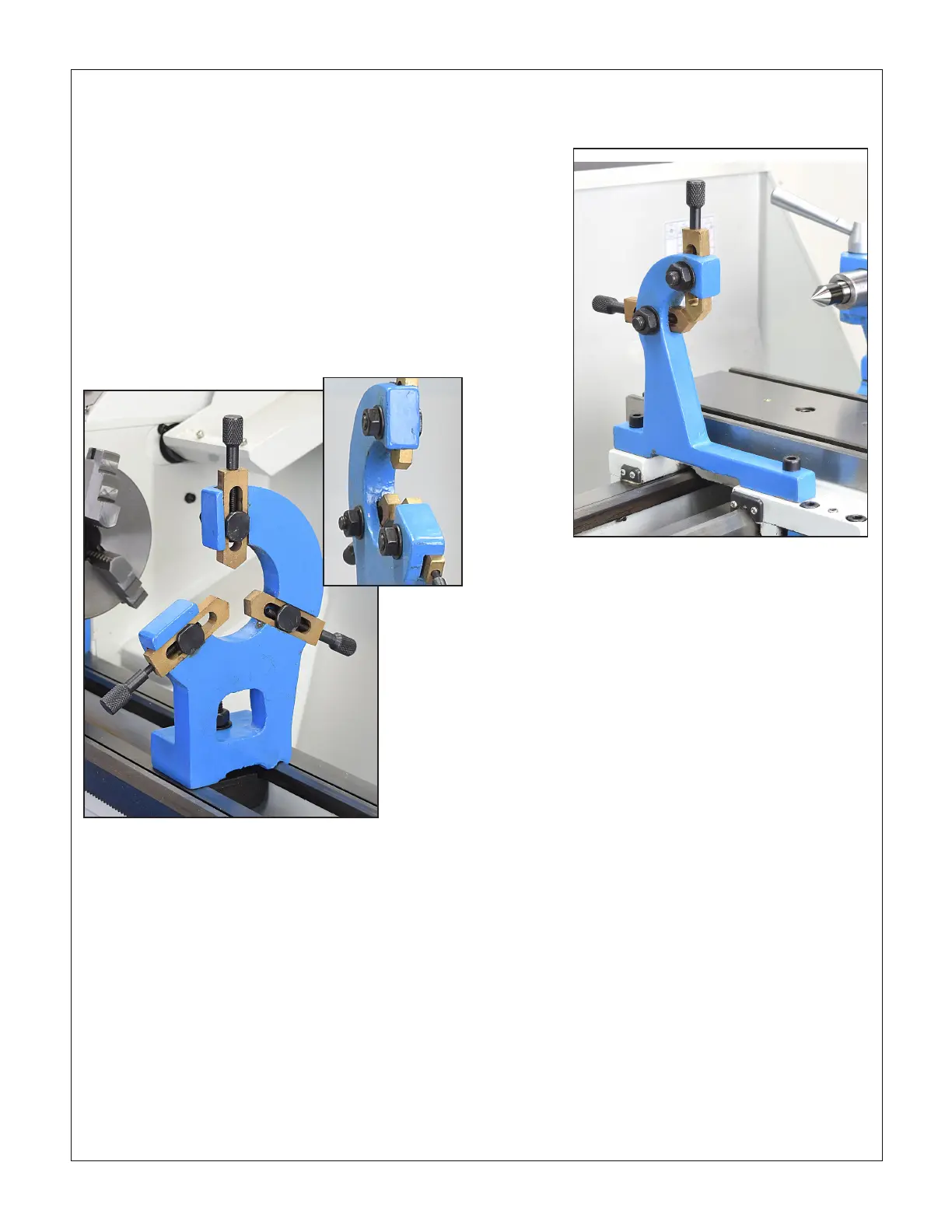

STEADY & FOLLOWER RESTS

Short, rigid workpieces mounted in a chuck can typically be

machined without additional support. Long, slender workpiec-

es need support near the cutting tool. There are two options for

this: 1. A tailstock center (usually a live center), or; 2. A steady

rest, Figure 3-17. This is often used in combination with the

saddle-mounted follower rest, Figure 3-28.

The tailstock center can be used with any size and shape of

workpiece (such as non-symmetrical castings), but it may ob-

struct the turning tool for facing operations, and it also may

disallow drilling or tapping with a tailstock chuck.

On the other hand the steady rest does allow face turning and

tailstock chuck operations; however, it can only be used if the

outboard end of the workpiece is circular and centered on the

lathe axis with practically zero runout.

The step-by-step procedure for setting up the steady rest de-

pends on personal preferences. Some users start by xing the

steady rest casting on the bed, then mounting the workpiece

in a chuck (or between centers); others set up the workpiece

rst, then install the steady rest on the lathe bed. Either way,

the region of the workpiece under the steady rest ngers must

run true, and the ngers must not apply any o-axis loading.

To set up the steady rest, loosen the three hex nuts, inset pho-

to, then back out the thumbscrews to spread the ngers be-

yond the workpiece diameter. Tighten the nuts just enough to

allow the thumbscrews to push the ngers inward. Fully tighten

the nuts when the ngers are gently touching — but not de-

ecting — the workpiece. Apply oil frequently at the contact

points while machining.

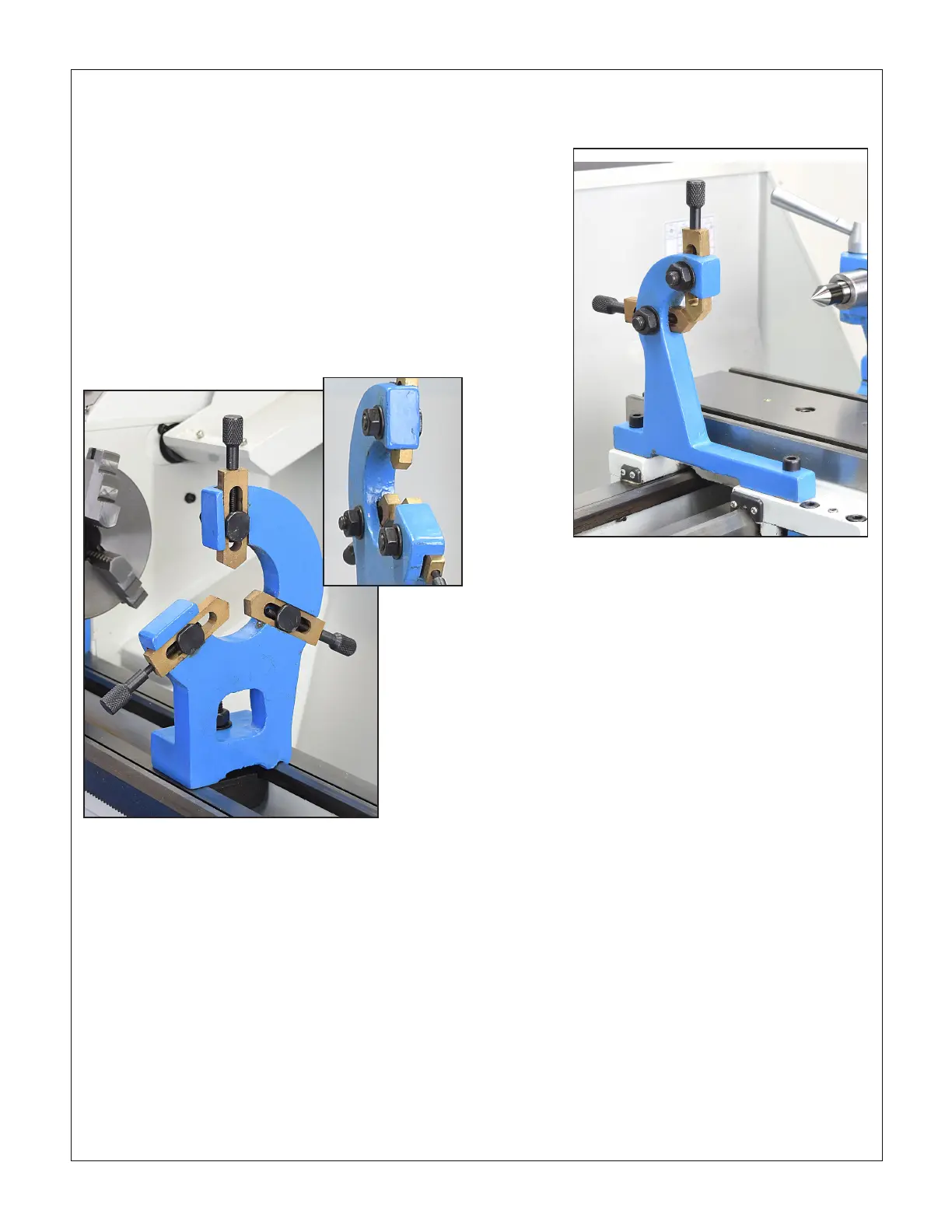

The follower rest helps prevent exing of the workpiece by pro-

Figure 3-28 Follower rest Maximum diameter 1 in.

Figure 3-27 Steady rest Maximum diameter 1-1/2 in.

viding support directly ahead of the cutting tool, Figure 3-29.

It is secured to the saddle with two 8 mm socket head screws.

Loading...

Loading...