23

PM-1030V v5 2020-10 Copyright © 2020 Quality Machine Tools, LLC

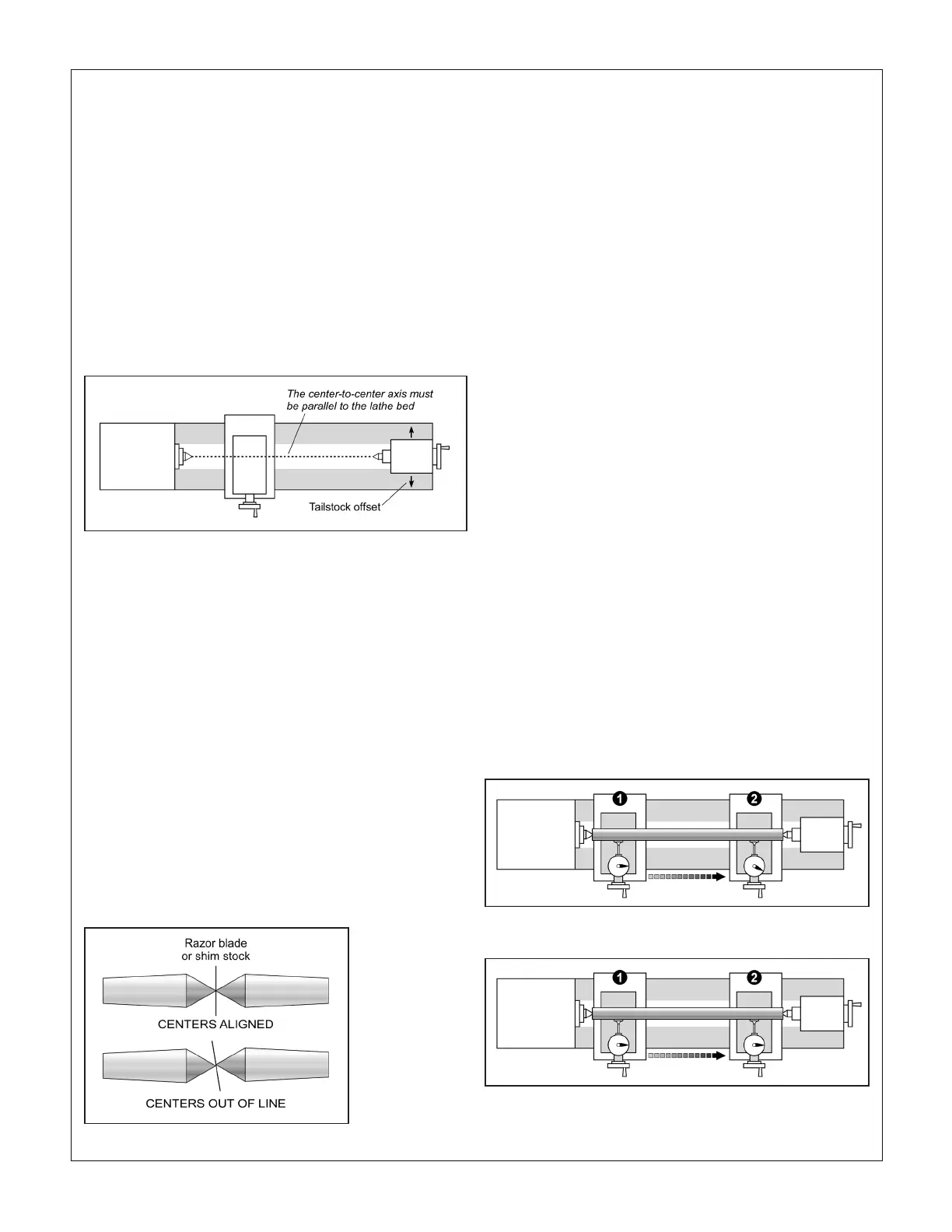

Figure A Center-to-center axis

ALIGNING THE LATHE

The most important attribute of a properly set up lathe is its

ability to “machine parallel”, to cut a cylinder of uniform diame-

ter over its entire length. In other words, no taper.

Leveling of the lathe is a part of this, see Section 1. Equally

important is the alignment of the center-to-center axis with the

lathe bed, as seen from above. [Vertical alignment is nowhere

near as critical, rarely a cause of taper unless the lathe is dam-

aged or badly worn.]

How to align lathe centers

The tailstock may be oset for taper turning and other oper-

ations. For routine operations, the oset must be precisely

zero, Figure A.

Precise method

This method uses a precision ground steel rod at least 10"

long. Look for 3/4 or 1 inch "drill rod" with a diameter tolerance

of ± 0.001" or less.

Straightness and uniform diameter are both important

(absolute diameter is not).

1. Set the rod in a collet chuck, or independent 4-jaw chuck,

with the outer end about 1/2 inch clear of the chuck.

2. Use a dial indicator to check for runout. If using a 4-jaw

adjust as necessary for minimum TIR (aim for 0.0005" or

less).

3. Center-drill the end of the ground rod.

4. Reverse the rod, re-adjust for minimum TIR, then drill the

other end.

5. Set the drill rod snugly between centers, as Figure C. Lock

the tailstock.

6. Set a dial indicator on the cross-slide (to eliminate vertical

error use a at disc contact, not the usual spherical type —

if a disc contact is not available, machine a cap to t over

the spherical point).

7. Starting at location (1), note which way the pointer rotates

when the cross-slide is moved inward. (In this diagram the

pointer is shown turning clockwise.)

8. Pre-load the indicator by a few thousandths, then traverse

the saddle from (1) to (2).

If the pointer turns clockwise as you go toward the tailstock, as

Figure C, the tailstock is biased to the front. This will cause the

lathe to cut a tapered workpiece with the larger diameter at the

headstock end. Correct this by a series of very small adjust-

ments to the tailstock oset, aiming for the perfect result — no

pointer movement from (1) to (2), Figure D.

The scale provided on the tailstock is not reliable for pre-

cision work — think of it as only a starting point. What follows

are two methods for aligning centers, one quick and easy, the

other more precise.

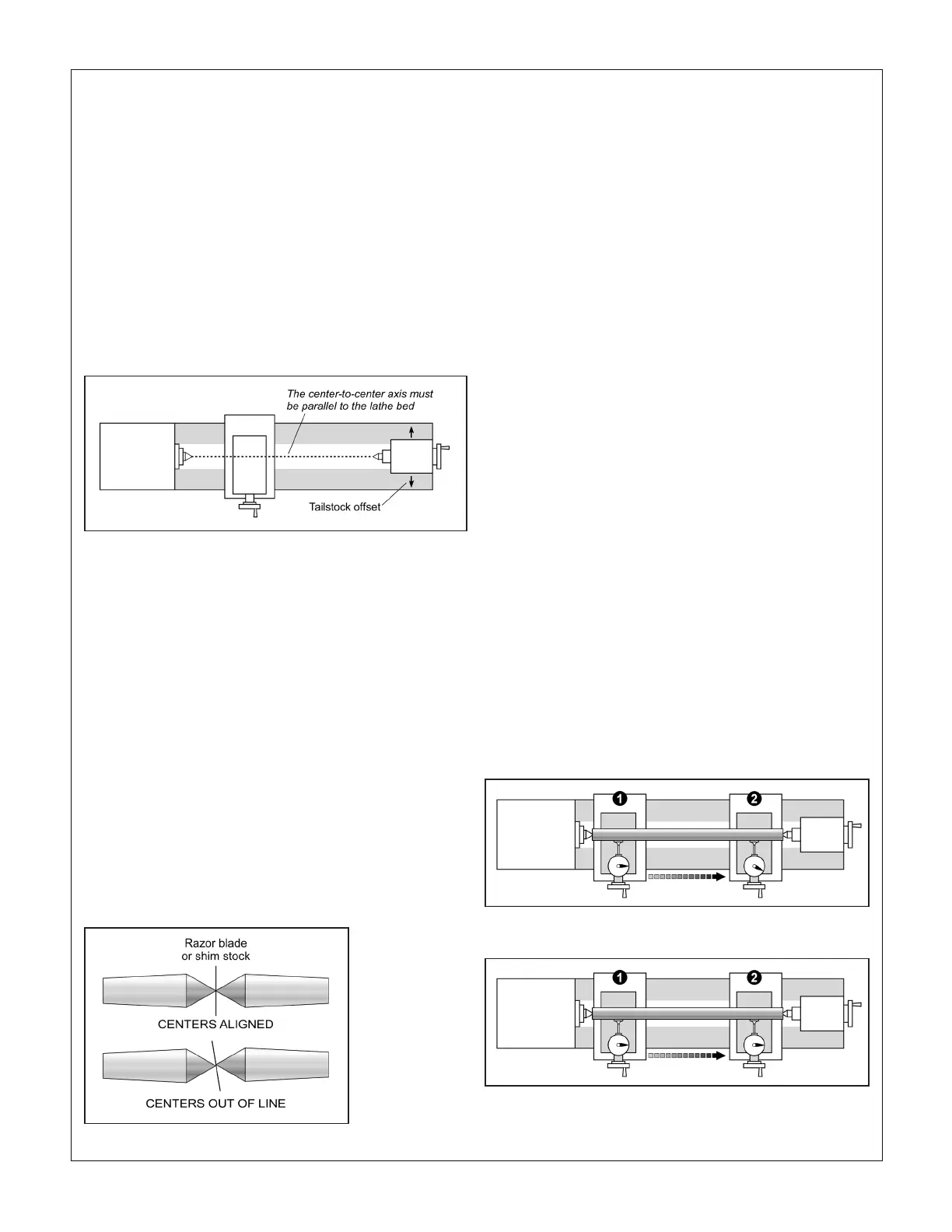

Quick method

This method works only if the centers are in new condition,

sharp and clean.

1. Carefully clean the taper sockets and the tapers them-

selves. Install the tapers.

2. Move the saddle left as far as it will go, then slide the

tailstock left to touch the saddle.

3. Lock the tailstock (this is important — unlocked to locked

can mean an oset of several thousandths). Try to use the

same locking force every time you move the tailstock.

4. Advance the tailstock quill to bring the centers together.

5. Place a scrap of hard shim stock or an old-style dou-

ble-edge razor blade between the centers, Figure B.

6. Advance the tailstock quill to trap the blade, then lock the

quill. If the centers are aligned, the blade will point squarely

front to back. If not, adjust the tailstock oset by a series of

very small adjustments.

7. If the range of quill motion permits, check the blade align-

ment at various extensions of the quill. There should be no

appreciable variation.

Figure C Drill rod between misaligned centers

Figure B Quick alignment check

Figure D Perfect alignment: zero indicator change between

locations 1 and 2

Loading...

Loading...