1-800-255-5387 • www.premier-mfg.com

PREMIER MANUFACTURING COMPANY

Page 7

Model 330 / 330A Hinge Assembly

INSTALLATION

bore from the opposite end of the 359 Flange

(see Figure 4). Using a rubber mallet only, tap

the taper pin into the bracket until the head of

the taper pin is flush against the bracket.

15. Place one 321D Washer onto the 321B Bolt

and slide it through the 352 Taper pin. Place

the second 321D washer and 321C Locknut

onto the end of the 321B bolt. Prior to

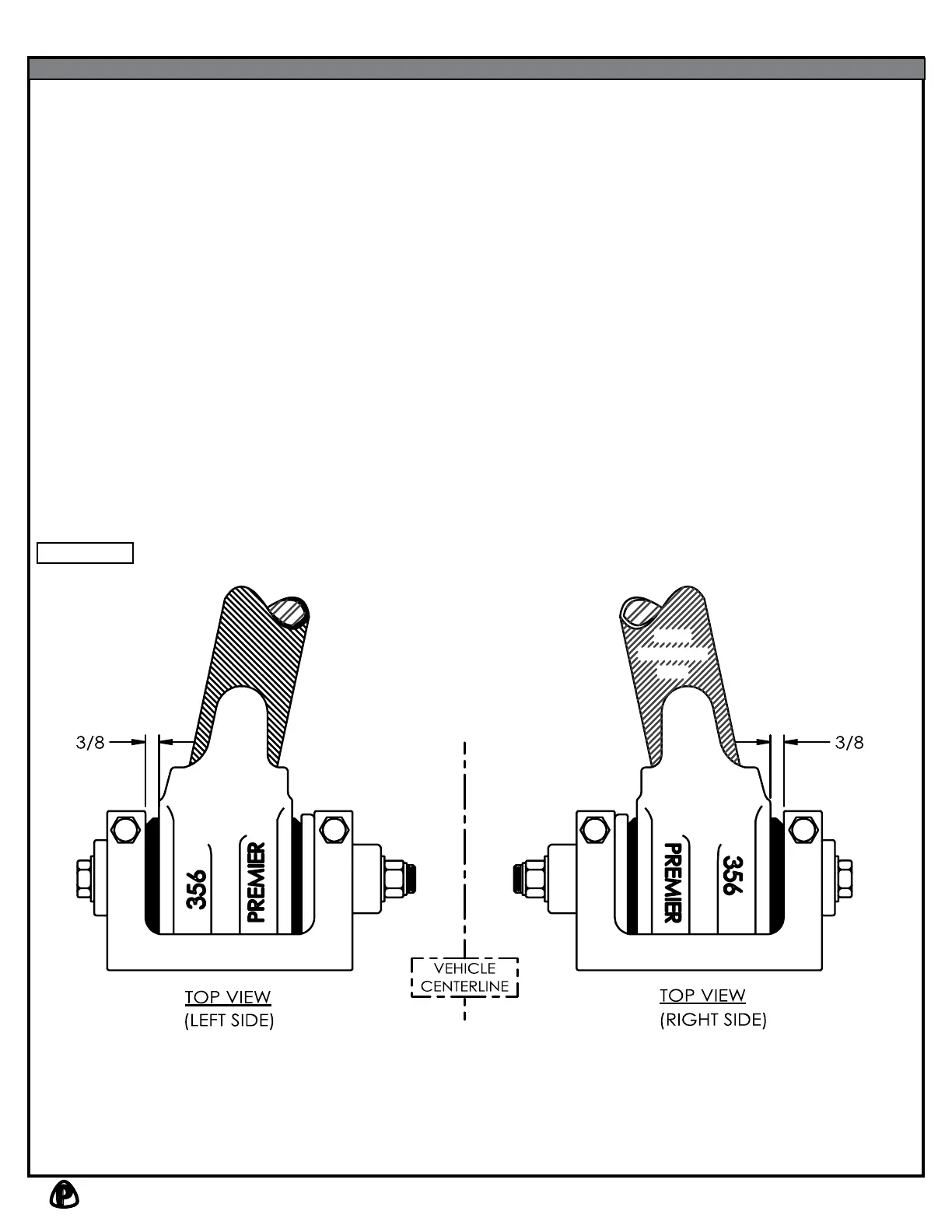

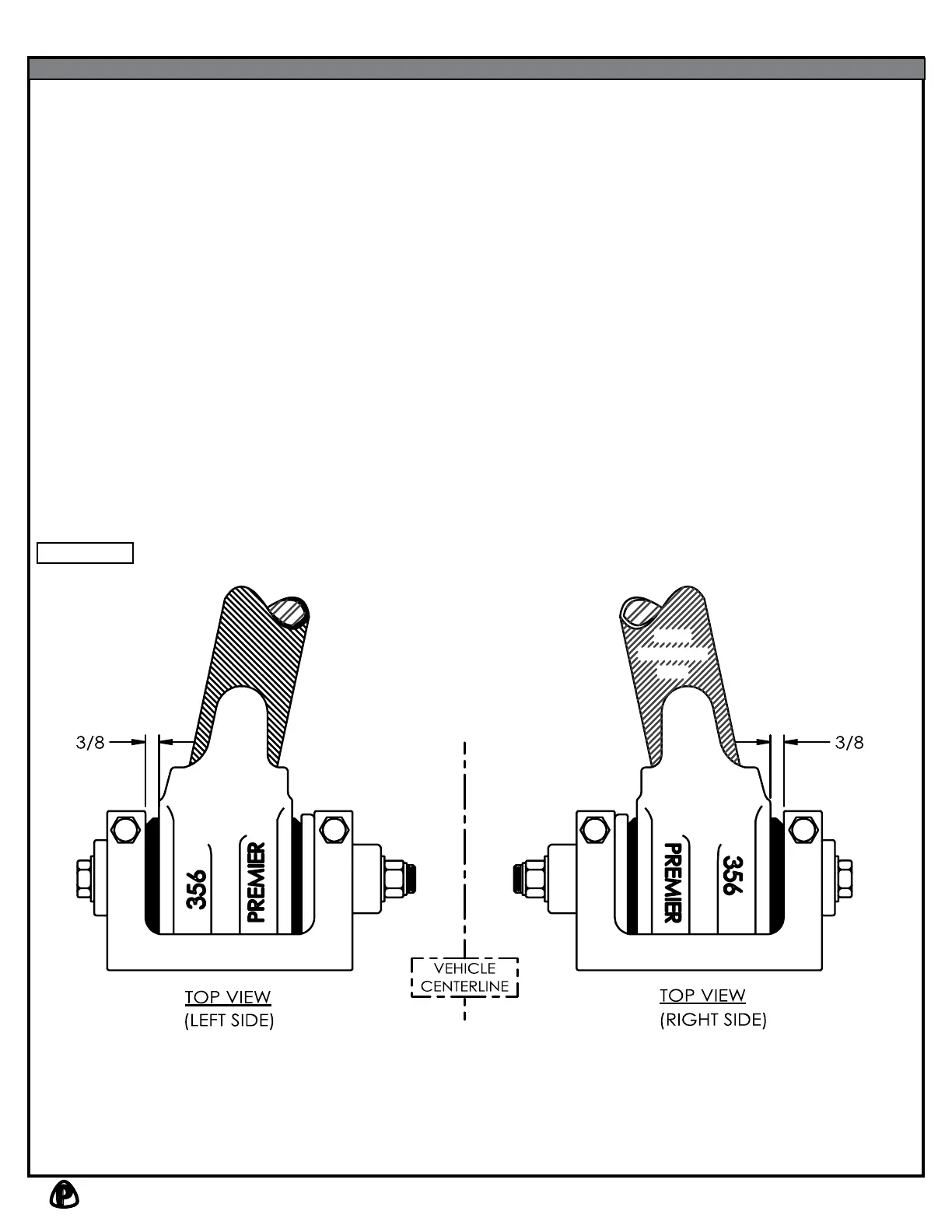

tightening, check to make sure the 3/8” gap

between the 356 Housing and 350 Bracket

exists (see Figure 1).

16. Torque the 321C Locknut to 60 ft-lbs. Test

the hinge assemblies for desired rotational

stiffness. If a stiffer hinge is desired, tighten

the 321C Locknut in 10-20 ft-lb increments.

DO NOT EXCEED 200 ft-lbs of TORQUE.

17. Tighten the 351 Bolts to 80 ft-lbs of torque.

These bolts compress the 350 Bracket,

clamping both the 359 Flange and 352 Taper

pin. Note: Both 351 Bolts must be loosened

prior to any future adjustment of the of the

321B Bolt for hinge stiffness. After adjustment,

the 351 Bolts must be retorqued to 80 ft-lbs.

18. An “IMPORTANT WARNINGS!” sticker was

enclosed. This must be attached to the front

end, adjacent to the drawbar eye, visible for the

end user to read.

2 1/2"

FRONT END

TUBE

Figure 1

Loading...

Loading...