5

In pressure canning, some of the water in the canner is converted to steam, which creates pressure within the canner. This pressure is

what allows the canner to reach temperatures above boiling. At 240°F, this pressurized heat destroys the potentially harmful bacterial

spores. Step-by-step instructions for Pressure Canning begin on page 7.

As jars cool after processing (by either the boiling water or pressure canning method), a vacuum is formed, sealing food within and

preventing any new microorganisms from entering and spoiling the foods.

Before Beginning

Selecting a recipe

To produce home canned food that is safe for storage at room temperature, it is necessary to use a tested canning recipe. Recipes that

have been handed down through the years or those found on the web are oftentimes unreliable and usually do not include scientically

tested processing procedures that are vital to a successful and safe canning project. Canning information published prior to 1994 may

be incorrect and could pose a serious health risk. A tested canning recipe has been evaluated to determine the accurate processing

method (boiling water canning or pressure canning) as well as the processing time. Do NOT can leftovers; it is not safe.

Always choose recipes from a reliable resource, such as the National Center for Home Food Preservation (nchfp.uga.edu), your local

Cooperative Extension Service, or this instruction book.

Selecting Jars

Glass home canning jars, sometimes referred to as Mason jars, are made of heat-tempered glass for durability and reuse. These are the

only jars recommended for safe home canning. They are available in standard sizes (half-pint, pint, and quart jars) and will withstand

the heat of a pressure canner. The diameter of Mason jars may vary from one manufacturer to another.

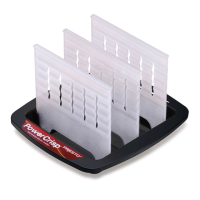

Before lling Mason jars, test load your canner. When pressure canning, it will be necessary to double-deck half-pint wide mouth jars

to reach the maximum capacity, as indicated in the chart on page 4. To double-deck, stagger the jars by placing one jar on top of two

(Fig. I, page 4). Jars may touch. Do not double-deck jars for the boiling water method.

The canning rack which accompanied your canner must be placed on the bottom of the canner to prevent jar breakage. Although it

is not necessary to use a rack between layers of jars, if you wish to do so, a rack can be ordered from the Presto Consumer Service

Department (see page 30).

Canning Lids and Bands

The two-piece vacuum cap (lid and band) is the recommended closure for home canning. It consists of a at metal lid with a sealing

compound on the outer edge and a separate metal screw band that secures the lid during processing. The at lid is for one use only

while the bands can be used repeatedly if they remain in good condition. Do not use dented or rusty bands. Use only jars, lids, and

screw bands in perfect condition so an airtight seal may be obtained. Bands should be removed prior to storage.

Measuring Headspace

Headspace is the air space between the top of the food or its liquid and the lid. Leaving too much headspace can result in underprocessing

because it may take too long to release the air from the jar. Leaving too little headspace will trap food between the jar and the lid

and may result in an inadequate seal. As a general rule, allow ¼-inch headspace for jams and jellies; ½-inch headspace for fruits

and tomatoes; 1-inch for vegetables, meats, and seafood; and 1¼-inch for poultry. All recipes will indicate the amount of headspace

necessary for the food being canned.

Removing Air Bubbles

After food has been packed in jars, any air bubbles must be removed. Trapped air bubbles may rise to the top during processing,

causing too much headspace. Work quickly to remove air bubbles that have become trapped between the pieces of food by moving a

clean, nonmetal spatula around the jar between the food and side of the jar.

Preparing Jar Rims and Adjusting Lids and Bands

Immediately after lling, wipe jar rims with a clean, damp cloth to remove any residue. Any food particles, such as seeds, grease,

or syrup, on the rim of the jar may prevent the jar from sealing. Center a at lid on the jar rim, making sure the sealing compound is

touching the glass. Position a band over the lid and, using your ngertips, screw it onto the jar evenly and rmly (ngertip tight). Do

not overtighten as air must release from the jars during processing and cooling.

Loading...

Loading...