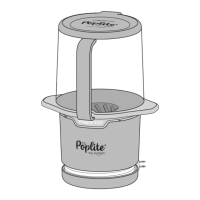

Heating plate

Fig. J

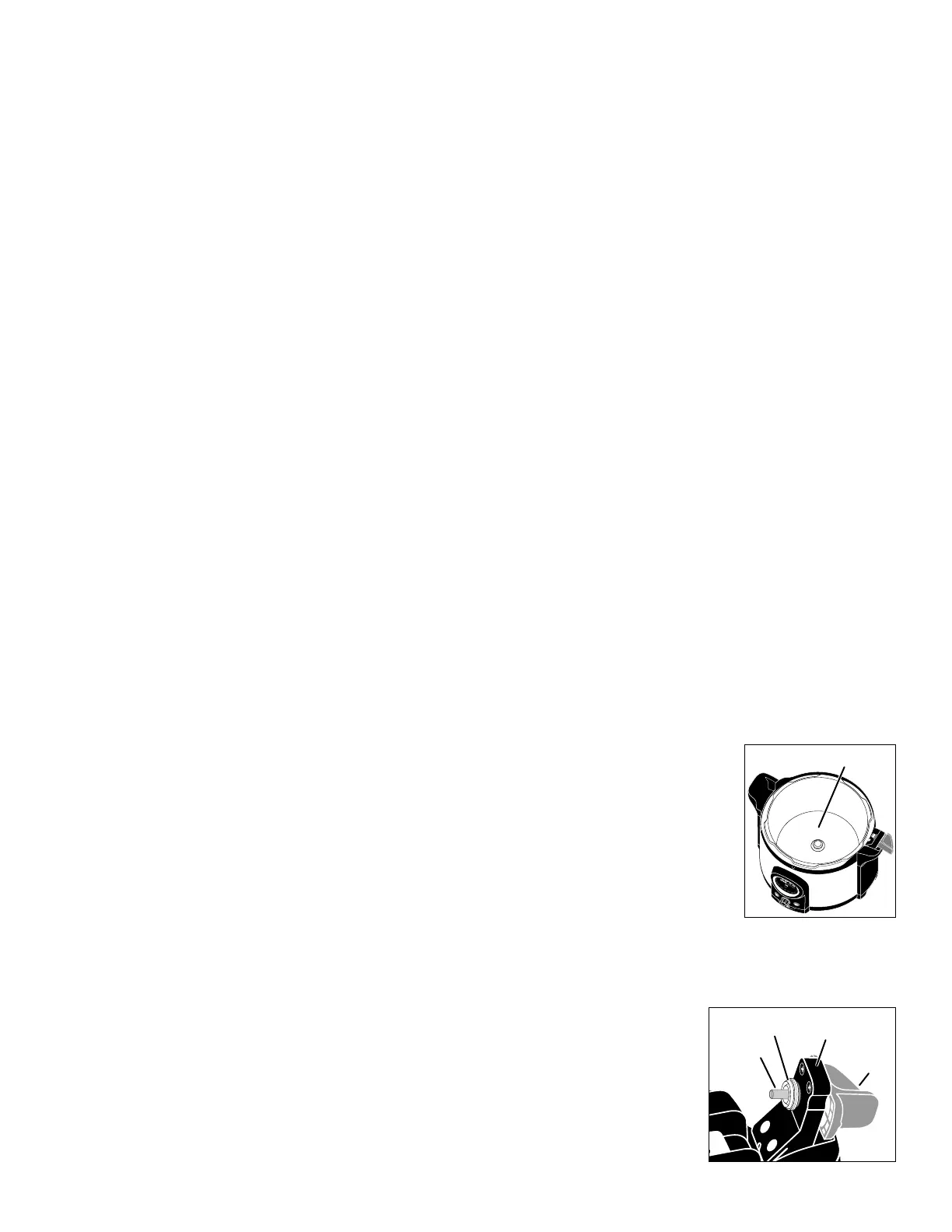

Fig. K

Gasket

Sensor

Temperature

sensor arm

Green

latch

6

After Processing

Cooling Jars

After processing, remove jars to a dry towel on countertop away from drafts. Leave 1 to 2 inches of space between jars to allow for

even cooling. Do not retighten bands. Do not invert jars or cover with a cloth. Allow jars to cool naturally. Check seals no earlier than

12 hours, but no later than 24 hours.

Bubbles often appear in the jar after removal from the canner because food is still boiling in the jar. Ordinarily bubbles do not appear

once the product has been allowed to thoroughly cool.

Testing Seals and Storing Canned Food

After jars have cooled a minimum of 12 hours, but no more than 24 hours, test the jar lids to be sure a vacuum seal has formed. Press

down on the center of the at lid to determine if it is concave (stays down when pressed). Remove the screw band and gently try to lift

the lid with your ngertips. If the center does not ex up and down and you cannot lift the lid off, the lid has a good seal. Wipe off any

food residue from jars and lids. Date and label jars. Store in a cool, dark, and dry place.

If a jar does not seal, the food can be refrigerated and should be used within 3 days. Other options include freezing the food or repro-

cessing for the full amount of time per the canning recipe. If choosing to reprocess, remove the lids and reheat the food and/or liquid.

Pack food into clean, heated jars. Remove air bubbles and clean jar rims. Position new lids on jars and secure with bands. If more

than 24 hours have elapsed since the canner registered DONE, and the seal is faulty, the food is no longer safe. Discard at once.

Detecting Spoilage

If up-to-date instructions and processing times are followed carefully, spoilage is uncommon. However, it is still recommended to

check for signs of spoilage before tasting any canned food. Check for a broken seal, gassiness when opening, mold, sliminess, cloudi-

ness, or unpleasant odors. If any of these signs are present, discard the food. As a safeguard against using canned low-acid and tomato

products which may be affected with spoilage that is not readily detected, boil food 10 minutes for altitudes up to 1,000 feet above sea

level. Extend the boiling time by 1 minute for each 1,000 foot increase in altitude. Many times odors that cannot be detected in the

cold product will become evident by this method. If, after boiling, food does not smell or look right, discard it without tasting.

PREPARATION STEPS BEFORE CANNING

In order for the unit to function properly, always follow these instructions before each use:

● Place the electric canner on a dry, level surface. To avoid steam damage to cabinets, position it so the vent pipe and air vent/cover

lock are not directly under cabinets.

WARNING! A fully loaded canner can weigh in excess of 42 pounds. To avoid damage to the counter, always place the canner

on a surface that supports the weight of a fully loaded canner, such as the center of a kitchen counter or table. DO NOT place a

canner near the edge of a surface or on an overhang.

● Be sure the bottom of the removable pot and the heating plate within the canner body (Fig. J) are free

of debris before placing the pot in the canner body.

CAUTION! To prevent electrical shock and damage to the canner, NEVER USE THE UNIT

WITHOUT THE REMOVABLE POT. Also, be sure the outside of the pot is COMPLETELY DRY

before placing it into the canner body.

● Check both the vent pipe and vent lter to be sure they are clear and do not contain any debris. In

order to check the vent pipe, you will need to remove the regulator from the cover (Fig. A, page 3).

Then hold the cover up to the light and make sure you can see light coming through the vent pipe. If

you cannot, remove the sealing ring frame and vent lter (see page 3) and clean the vent pipe with a

small brush or pipe cleaner to remove the blockage. Reattach the vent lter and the sealing ring frame

to the cover.

● Always verify that the sealing ring frame is properly attached to the canner cover before canning and make sure the sealing ring is

positioned correctly on the metal frame (Fig. H, page 4).

● Always make sure the gasket is positioned on the sensor (Fig. K).

● Check Mason jars for nicks, cracks, and sharp edges. Check screw bands for dents or rust. Use

only jars, lids, and screw bands in perfect condition so an airtight seal may be obtained.

● Wash and rinse jars, lids, and screw bands. Follow closure manufacturer’s directions for

preparing lids.

Loading...

Loading...