Section 00 : GENERAL INFORMATION

PA1561 3

STEEL – STEEL WELDING

Caution: Before welding, disconnect electronic modules and battery terminals.

Warning: Welding surfaces must be free of scale, slag, rust, paint, grease, humidity or other foreign material

that would render welding impossible.

Warning: Only a qualified and experienced person must do welding.

• FCAW (Flux Cored Arc Welding) process ;

• Electrode wire conforms to A5.20 AWS (American Welding Society) specifications ;

• E4801T-9-CH, type electrode wire with 0,045“ diameter (1,14 mm) ;

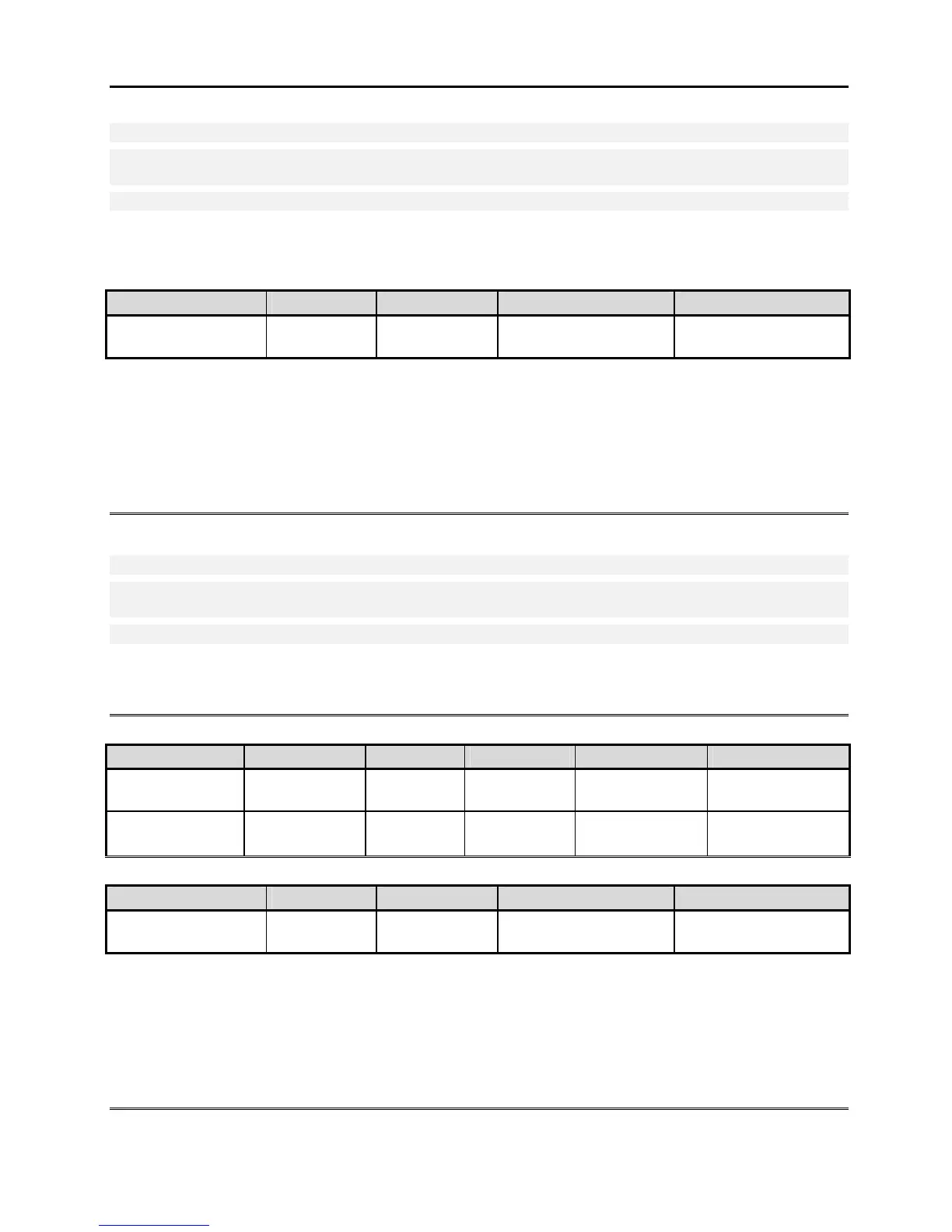

Material Thickness Voltage Current Wire Feed Rate Shielding Gas

1/8” to ½” 26 ± 2 volts 260 Amps 450 ipm. approx.

75% argon – 25% CO2

or 100% CO2

If necessary and with great care to prevent perforating the material, it is possible to use a conventional

electric arc welding machine according to the following specifications:

• SMAW (Shielded Metal-Arc Welding) process ;

• Welding rod conforms to A5.1 of AWS (American Welding Society) specifications; E 7018 type welding

rod with 1/8” diameter (3,2 mm).

• Current: 100 amperes to 150 amperes; optimum at 120 amps.

It is important to grind weld bead starts and stops and also to grind arc strikes from surfaces.

STEEL - STAINLESS STEEL OR STAINLESS STEEL - STAINLESS STEEL WELDING

Caution: Before welding, disconnect electronic modules and battery terminals.

Warning: Welding surfaces must be free of scale, slag, rust, paint, grease, humidity or other foreign material

that would render welding impossible.

Warning: Only a qualified and experienced person must do welding.

• GMAW (Gas Metal-Arc Welding) process;

• Welding wire conforms to AWS (American Welding Standards) A5.9 specifications;

• 308LSi type welding wire with 0.035" diameter (0,9 mm);

STEEL - STAINLESS STEEL WELDING

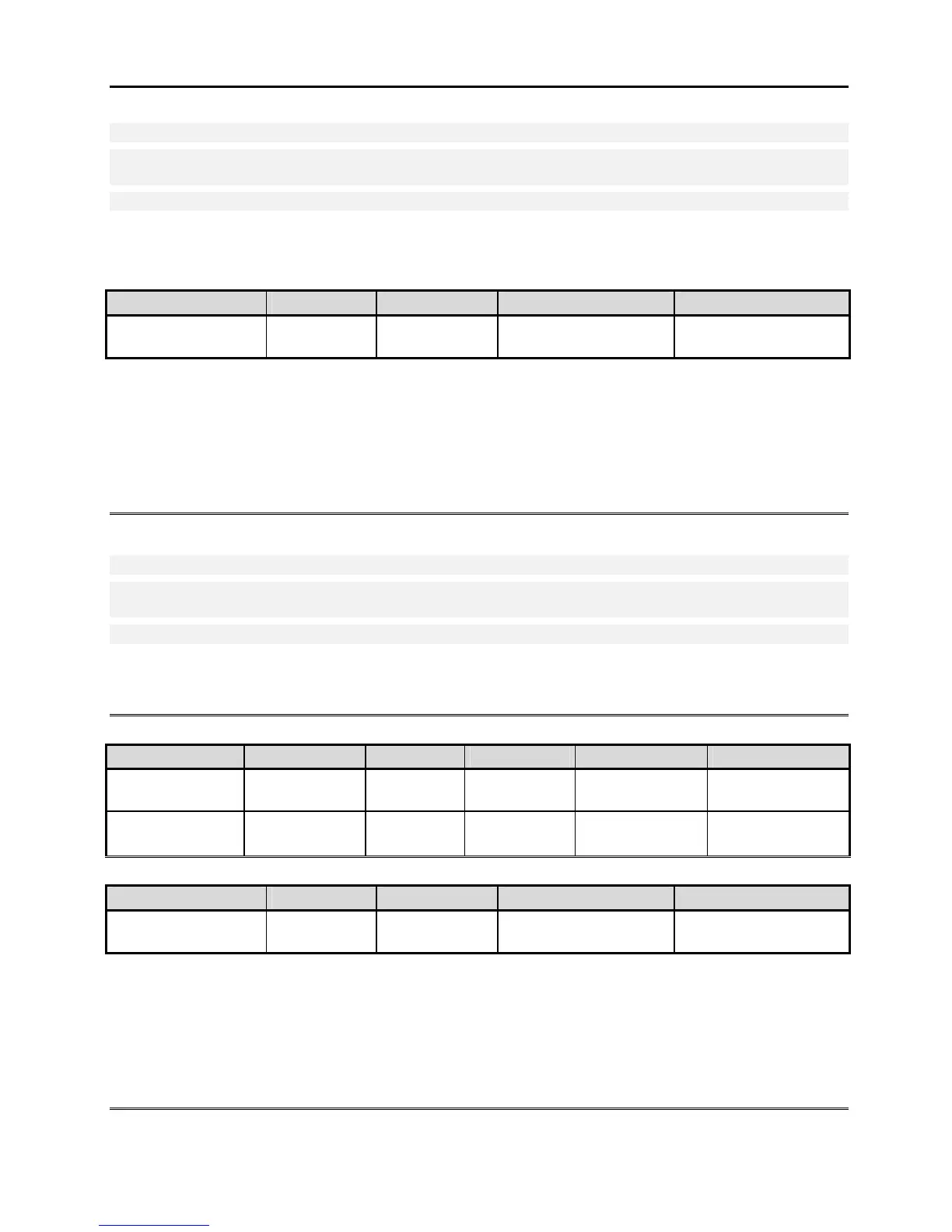

Steel Thickness SS Thickness Voltage Current Wire Feed Rate Shielding Gas

Less than 1/8” Any type 20±1.5 volts 130±15 Amps 290 ipm approx.

90% He, 7.5% Ar,

2.5% CO2

1/8” and more Any type 22±1.5 volts 160±15 Amps 330 ipm approx.

90% He, 7.5% Ar,

2.5% CO2

STAINLESS STEEL - STAINLESS STEEL WELDING

SS Thickness Voltage Current Wire Feed Rate Shielding Gas

Any type 20 ± 1.5 volts 130 ± 15 Amps 290 ipm approx.

90% He – 7.5% Ar,

2.5% CO2

If necessary and with great care to prevent perforating the material, it is possible to use a conventional

electric arc welding machine according to the following specifications:

• SMAW (Shield Metal-Arc Welding) process;

• Welding rod conforms to AWS (American Welding Standards) A5.4 specifications; 308L-17 type welding

rod with 3/32" diameter (2,4 mm);

• Current: - 50 amperes to 90 amperes, optimum at 60 amperes.

It is important to grind weld bead starts and stops and also to grind arc strikes from surfaces.

Loading...

Loading...