Section 3

Basic Theory and

Function

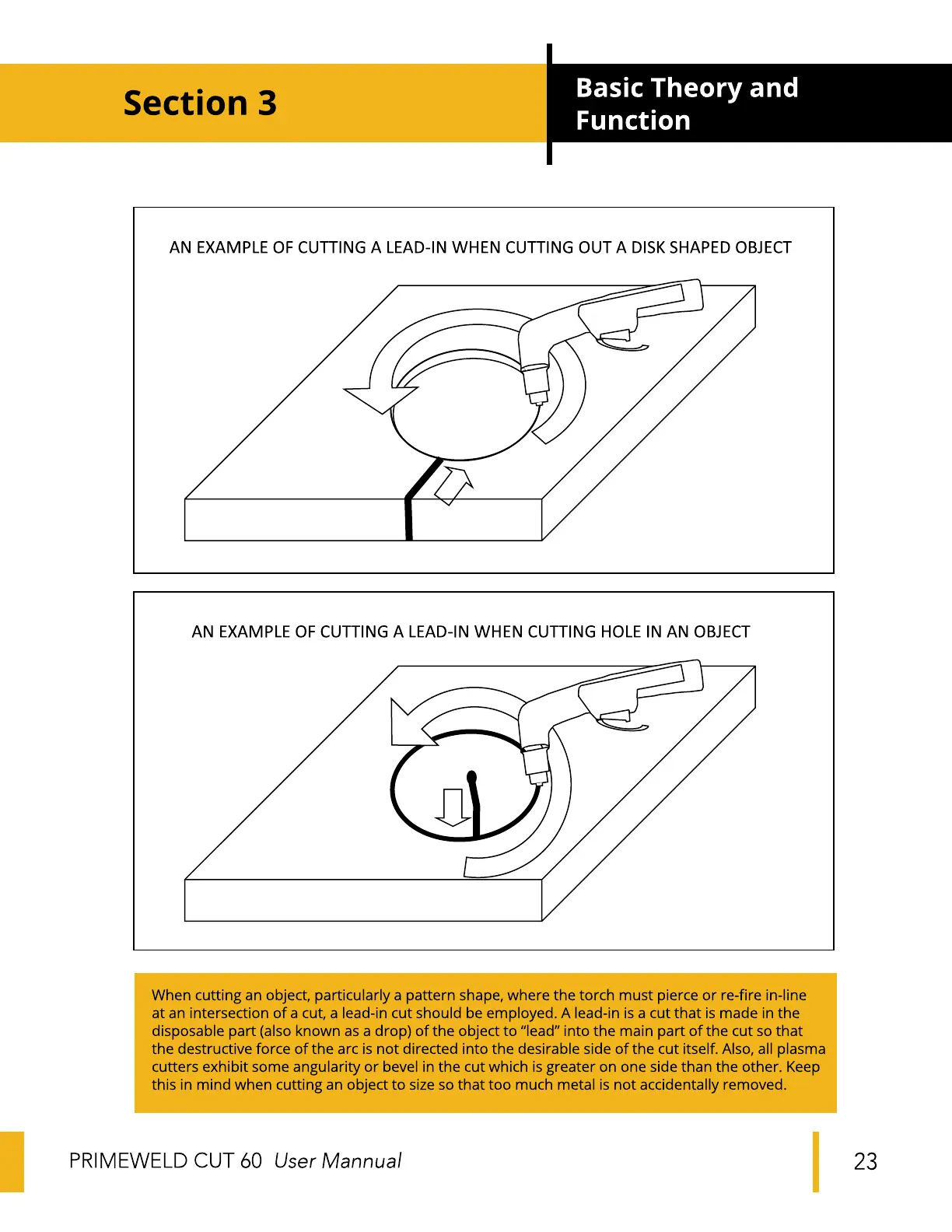

AN EXAMPLE OF CUTTING A LEAD-IN WHEN CUTTING OUT A DISK SHAPED OBJECT

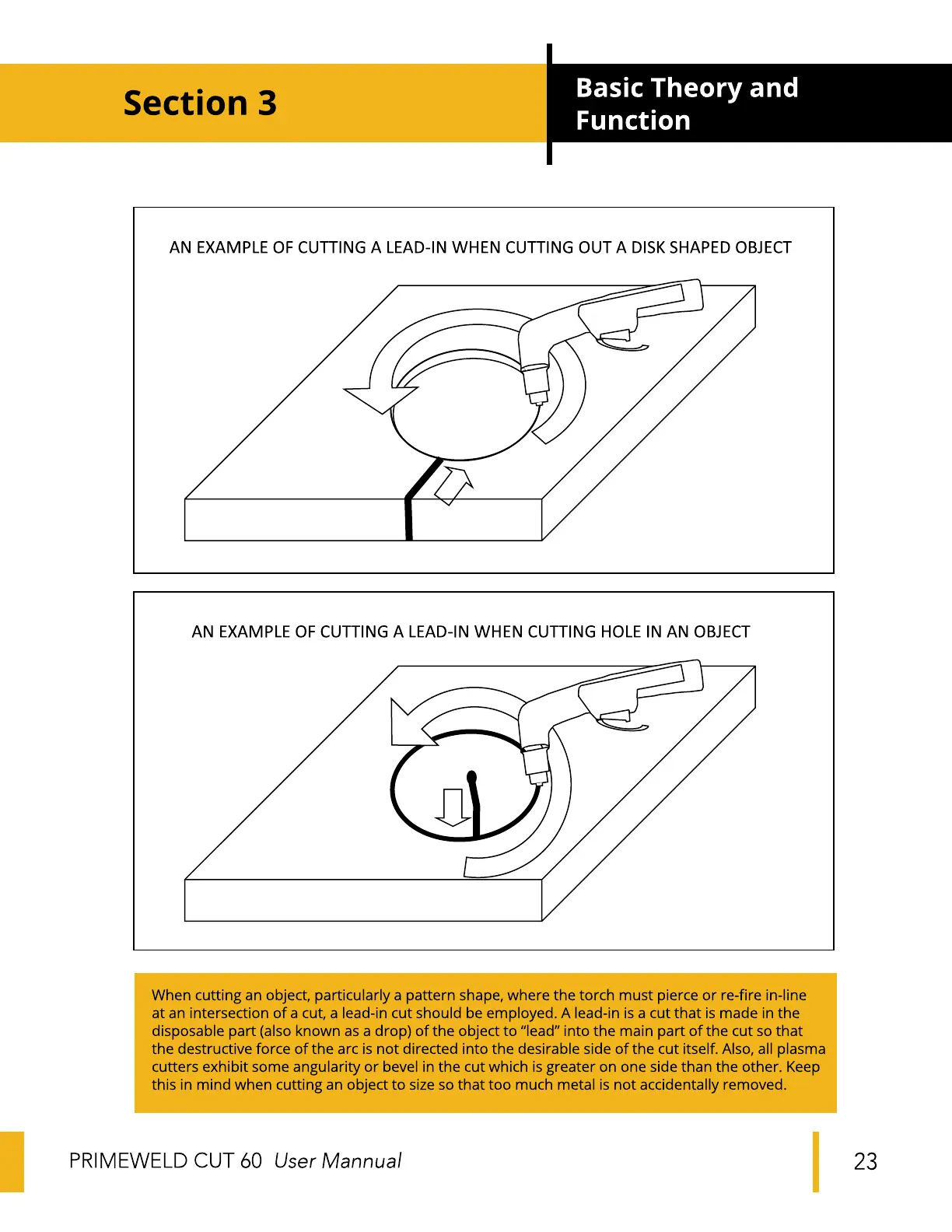

AN EXAMPLE OF CUTTING A LEAD-IN WHEN CUTTING HOLE IN AN OBJECT

When cutting an object, particularly a pattern shape, where the torch must pierce or re-fire in-line

at an intersection of a cut, a lead-in cut should be employed. A lead-in is a cut that is made in the

disposable part (also known as a drop) of the object to "lead" into the main part of the cut so that

the destructive force of the arc is not directed into the desirable side of the cut itself. Also, all plasma

cutters exhibit some angularity or bevel in the cut which is greater on one side than the other. Keep

this in mind when cutting an object to size so that too much metal is not accidentally removed.

PRIME-WELD CUT 60 User Mannual

23

Loading...

Loading...