Maintenance and

Section 4

Troubleshooting

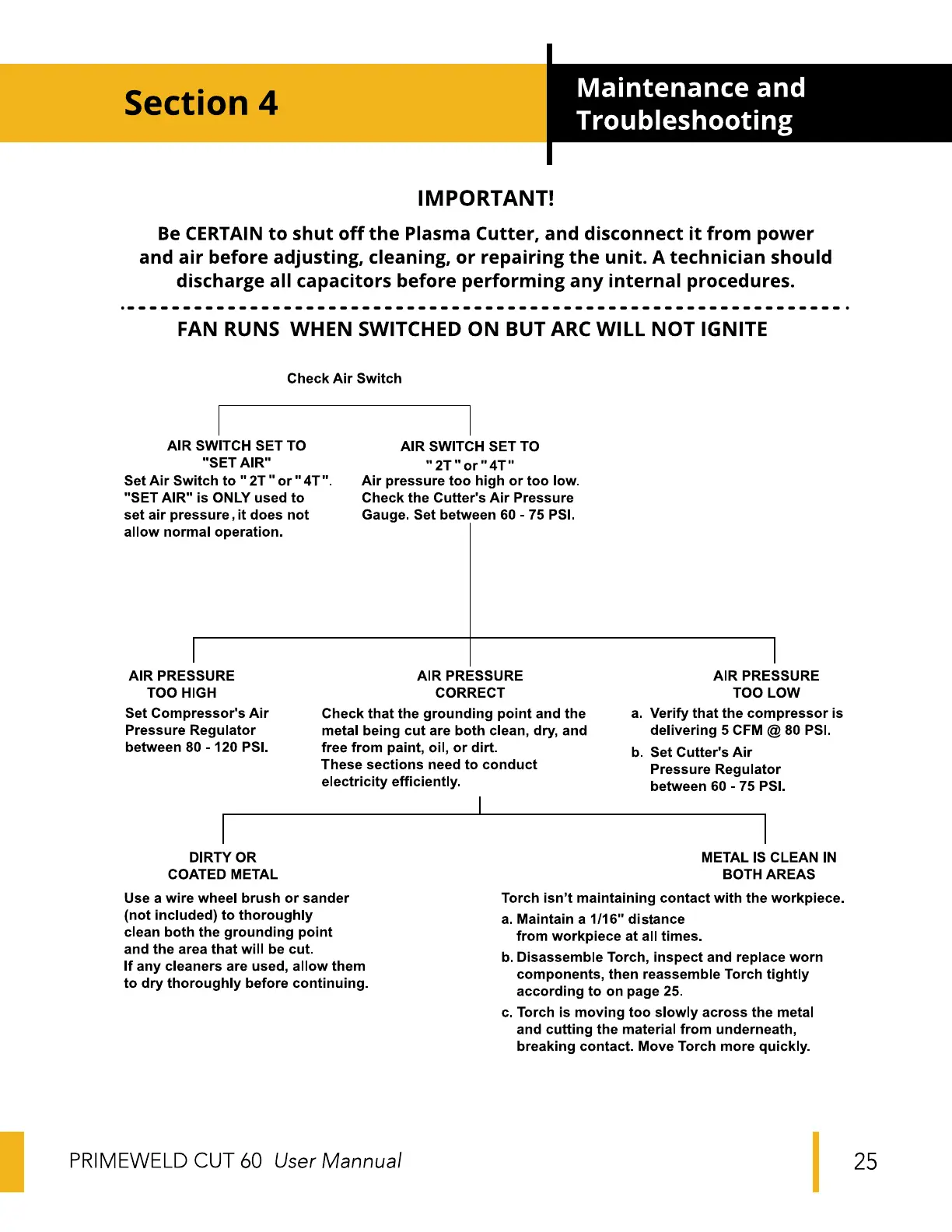

IMPORTANT!

Be CERTAIN to shut off the Plasma Cutter, and disconnect it from power

and air before adjusting, cleaning, or repairing the unit. A technician should

discharge all capacitors before performing any internal procedures.

FAN RUNS WHEN SWITCHED ON BUT ARC WILL NOT IGNITE

Check Air Switch

AIR SWITCH SET TO

AIR SWITCH SET TO

"SET AIR"

" 2T " or " 4T"

Set Air Switch to " 2T " or " 4T".

Air pressure too high or too low.

"SET AIR" is ONLY used to Check the Cutter's Air Pressure

set air pressure , it does not Gauge. Set between 60 - 75 PS'.

allow normal operation.

AIR PRESSURE AIR PRESSURE

TOO HIGH CORRECT

Set Compressor's Air Check that the grounding point and the

Pressure Regulator

metal being cut are both clean, dry, and

between 80 - 120 PS'.

free from paint, oil, or dirt.

These sections need to conduct

electricity efficiently.

DIRTY OR

COATED METAL

a.

b.

AIR PRESSURE

TOO LOW

Verify that the compressor is

delivering 5 CFM @ 80 PS'.

Set Cutter's Air

Pressure Regulator

between 60 - 75 PS'.

METAL IS CLEAN IN

BOTH AREAS

Use a wire wheel brush or sander

(not included) to thoroughly

clean both the grounding point

and the area that will be cut.

If any cleaners are used, allow them

to dry thoroughly before continuing.

PRIME-WELD CUT 60

User Mannual

Torch isn't maintaining contact with the workpiece.

a. Maintain a 1/16" distance

from workpiece at all times.

b. Disassemble Torch, inspect and replace worn

components, then reassemble Torch tightly

according to on page 25.

c. Torch is moving too slowly across the metal

and cutting the material from underneath,

breaking contact. Move Torch more quickly.

25

Loading...

Loading...