Maintenance and

Section 4

Troubleshooting

IMPORTANT!

Be CERTAIN to shut off the Plasma Cutter, and disconnect it from power

and air before adjusting, cleaning, or repairing the unit. A technician should

discharge all capacitors before performing any internal procedures.

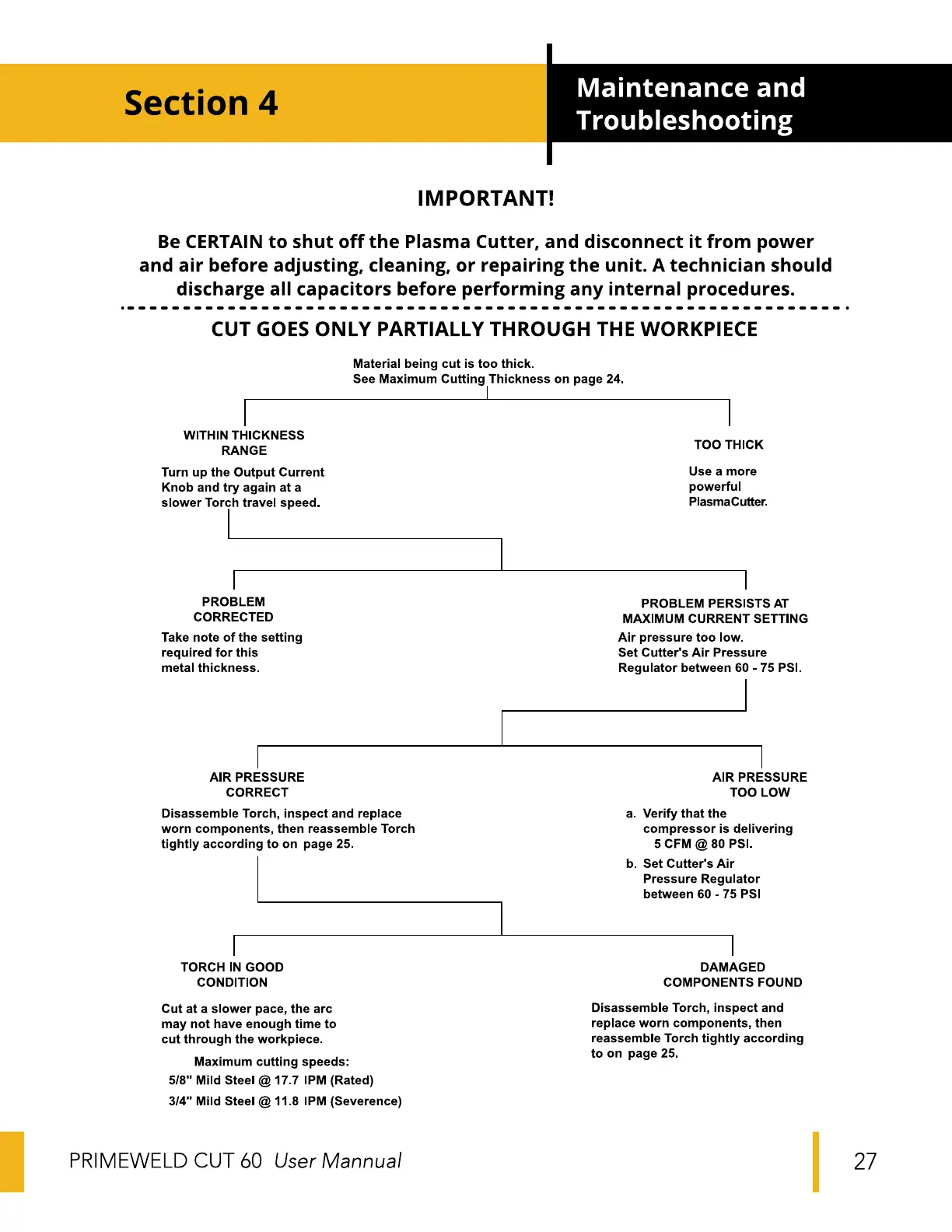

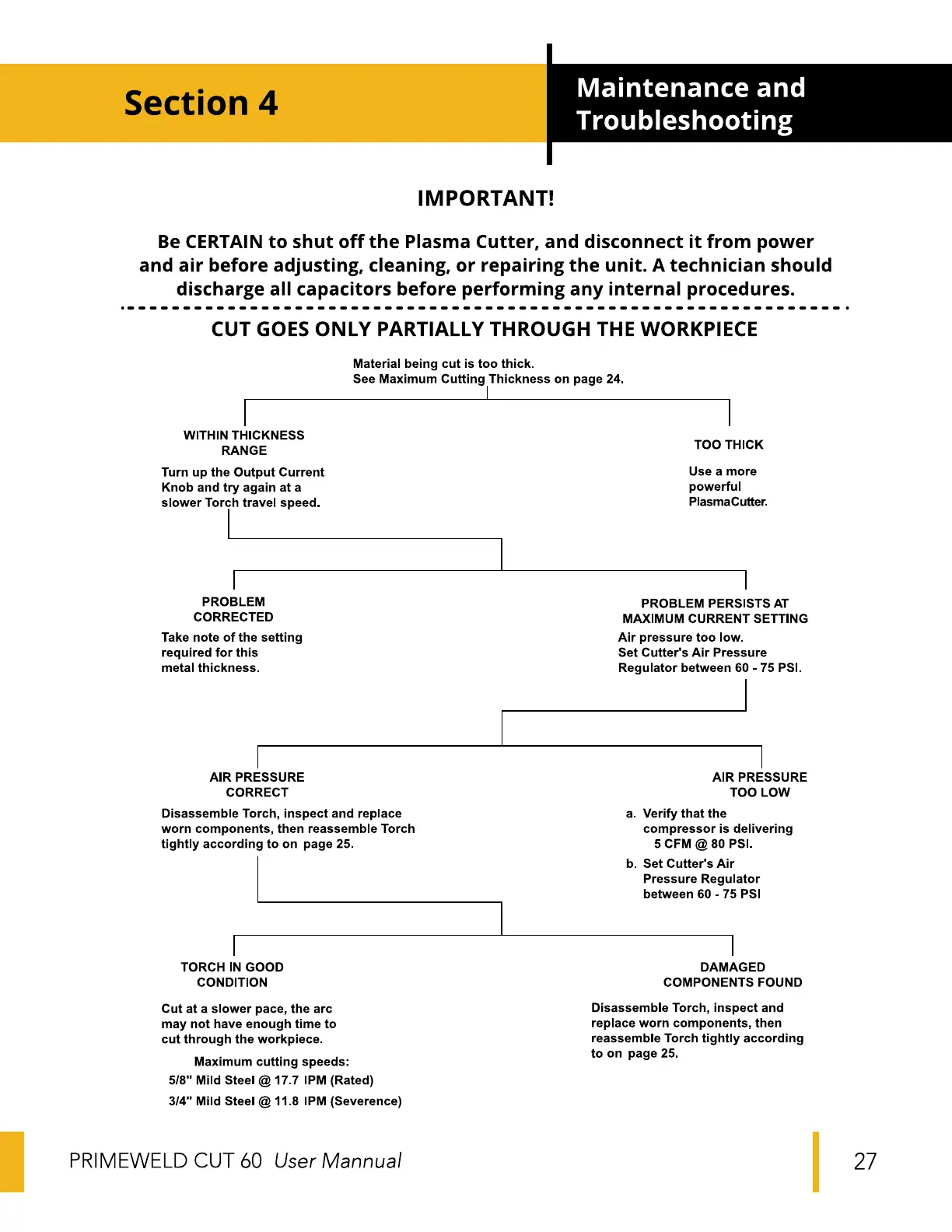

CUT GOES ONLY PARTIALLY THROUGH THE WORKPIECE

Material being cut is too thick.

See Maximum Cutting Thickness on page 24.

WITHIN THICKNESS

RANGE

Turn up the Output Current

Knob and try again at a

slower Torch travel speed.

PROBLEM

CORRECTED

Take note of the setting

required for this

metal thickness.

AIR PRESSURE

CORRECT

Disassemble Torch, inspect and replace

worn components, then reassemble Torch

tightly according to on page 25.

TORCH IN GOOD

CONDITION

Cut at a slower pace, the arc

may not have enough time to

cut through the workpiece.

Maximum cutting speeds:

5/8" Mild Steel @ 17.7 'PM (Rated)

3/4" Mild Steel @ 11.8 'PM (Severence)

PRIME-WELD CUT 60 User Mannual

TOO THICK

Use a more

powerful

PlasmaCutter.

PROBLEM PERSISTS AT

MAXIMUM CURRENT SETTING

Air pressure too low.

Set Cutter's Air Pressure

Regulator between 60 - 75 PS'.

a.

b.

AIR PRESSURE

TOO LOW

Verify that the

compressor is delivering

5 CFM @ 80 PS'.

Set Cutter's Air

Pressure Regulator

between 60 - 75 PSI

DAMAGED

COMPONENTS FOUND

Disassemble Torch, inspect and

replace worn components, then

reassemble Torch tightly according

to on page 25.

27

Loading...

Loading...