8 INSTALLATION AND MAINTENANCE MANUAL PUBLICATION DATE 07/04 513289

– All passages and spaces the machine has to be transported through at installation should be reasonably

dimensioned to meet the height and width of the machine including the package.

– Never push, pull or press the components protruding from the contour line of machine (front part

of the machine, filling door, control elements, belt cover, water inlet and outlet pipes etc.).

MAKE SURE THAT THESE COMPONENTS ARE SECURED SO AS TO AVOID THEIR DAMAGE DURING

HANDLING AND INSTALLATION OF THE MACHINE.

– Make sure that the filling door are secured to avoid its opening during the handling.

– Lift the machine up by the fork-lift truck or by pallet trucks using a transport skid to which the machine has

been attached.

UNPACKING

After unpacking, check if the machine has not been damaged and if all the accessories are included

according to your order. Please, check the type of your machine on the machine label which is placed in electric

distributor and find appropriate information in the manual. Manual and accessories are placed inside the drum

which is possible to open according to chapter 6.1.

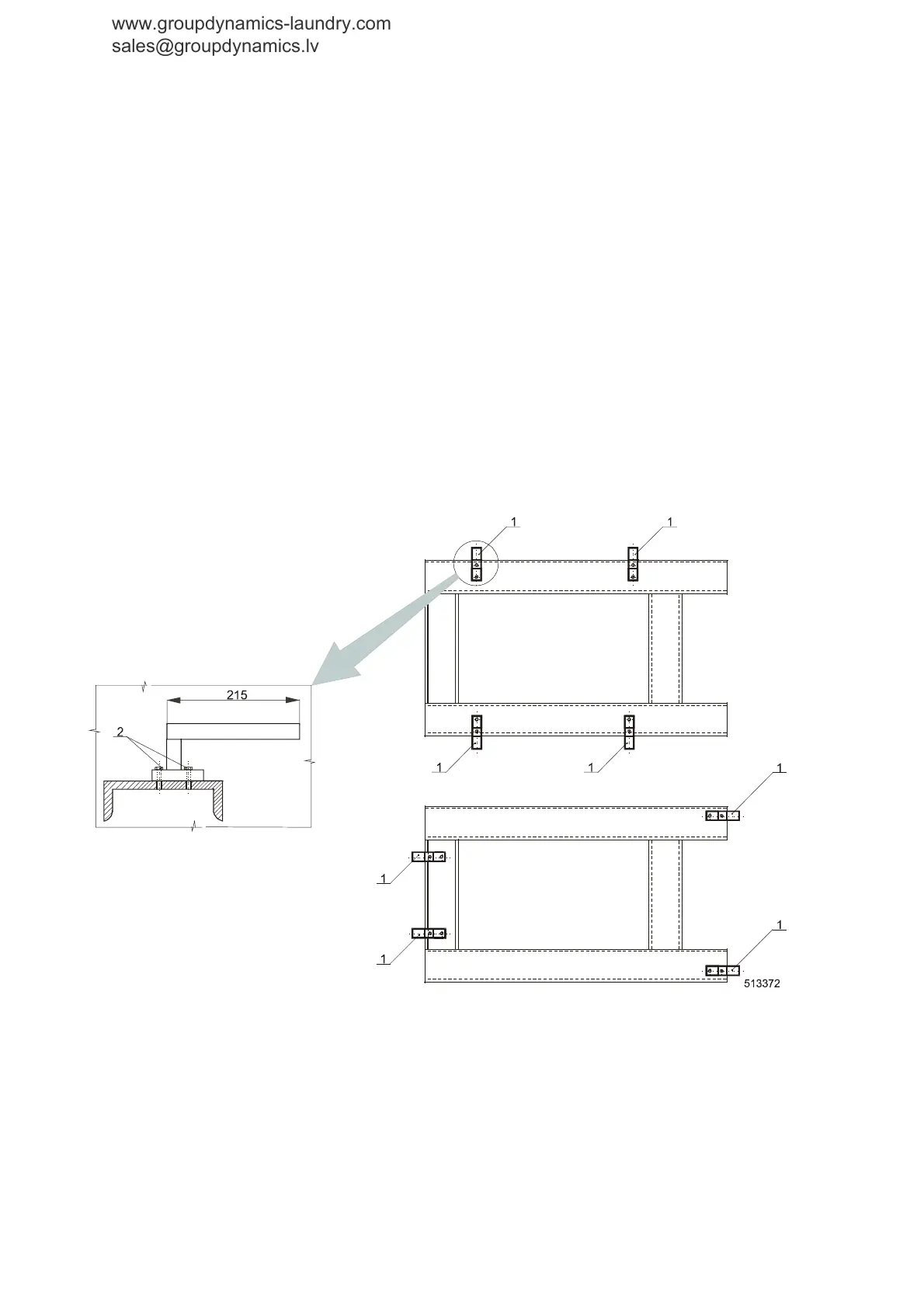

Before the machine is installed on the place, remove the packing, remove the frontal and side covers and remove

four screws which fix the machine to the pallet. According to fig. 4.1.D. use the lifting feet (4pcs), (1) and fix them

using the bolts M12 (2) to the machine frame.

(Feet and bolts are being the part of delivery).

For fixing the feet it is possible to use the following combination of positions:

– loading side (dirty) + unloading side (clean)

– side of pulley + side of inlet valves

Lift the machine up carefully using the pallet trucks and remove the wooden skids. Now, install the machine

on its final position carefully and remove the feet. Keep the feet for possible handling later on.

Fig.4.1.D. Lifting feet

HANDLING WITH HUNG MACHINE

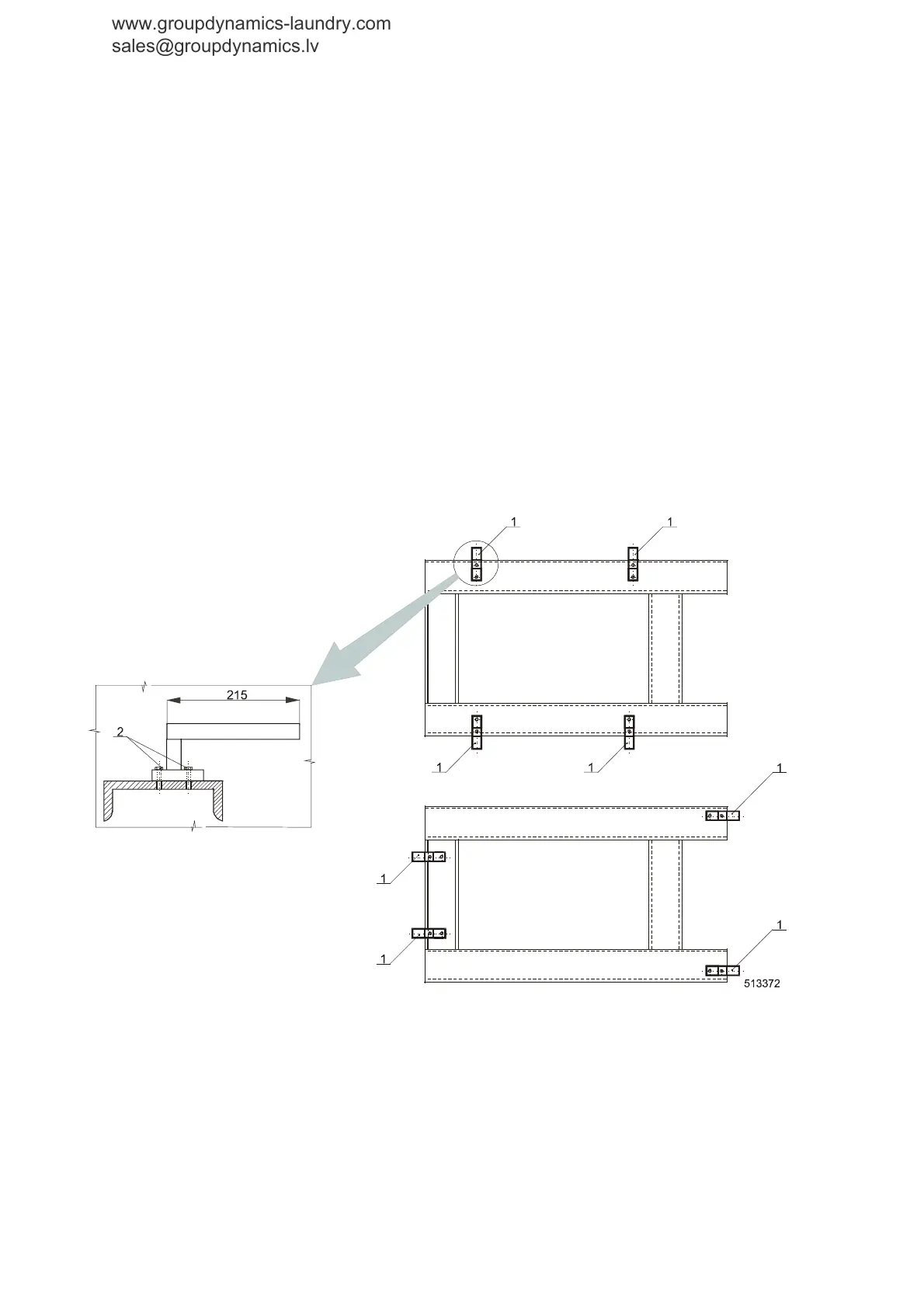

In case of need and under certain conditions, it is possible to handle the machine in hanging position.

All activities can be done only by a worker, who knows all information about the machine. Use four-point

suspension with recommended length of arm 1700 - 1800 mm for handling the machine in hanging position.

Four-point suspension must have minimum load capacity 10.000 kg. Do not use any loops (danger of the box

damage and electric distributor damage). If the machine is handled in hanging position, it must be hung on all

four eyes, fig. 4.1.E, pos.1 - ∅ 30 mm located in the machine front and there must be transport braces installed

on the machine.

DIRTY SIDE

CLEAN SIDE

SIDE OF INLET VALVES

SIDE OF PULLEY

www.groupdynamics-laundry.com

sales@groupdynamics.lv

Loading...

Loading...