17 EN | ENGLISH

operating the starter again.

If the speed of the starter motor drops after a period of time, it indicates

that the battery should be recharged.

When the engine starts, allow the engine switch to return to ON position.

Turn the choke lever or push the choke rod to OPEN position as the engine

warms up.

Stopping the engine in an emergency:

To stop the engine in an emergency, move the engine switch to OFF

position.

In normal use:

1. Turn the AC circuit breaker to OFF position. Disconnect the DC battery

charging cables.

2. Turn the engine switch to OFF position.

3. Turn the fuel valve to OFF position.

MAINTENANCE

Good maintenance is essential for safe, economical, and trouble-free

operation. It will also help reduce air pollution.

WARNING

Exhaust gas contains poisonous carbon monoxide. Shut off the engine

before performing any maintenance. If the engine must be run, make sure

the area is well-ventilated.

Periodic maintenance and adjustment is necessary to keep the generator

in good operating condition. Perform the service and inspection at the

intervals shown in the maintenance schedule below.

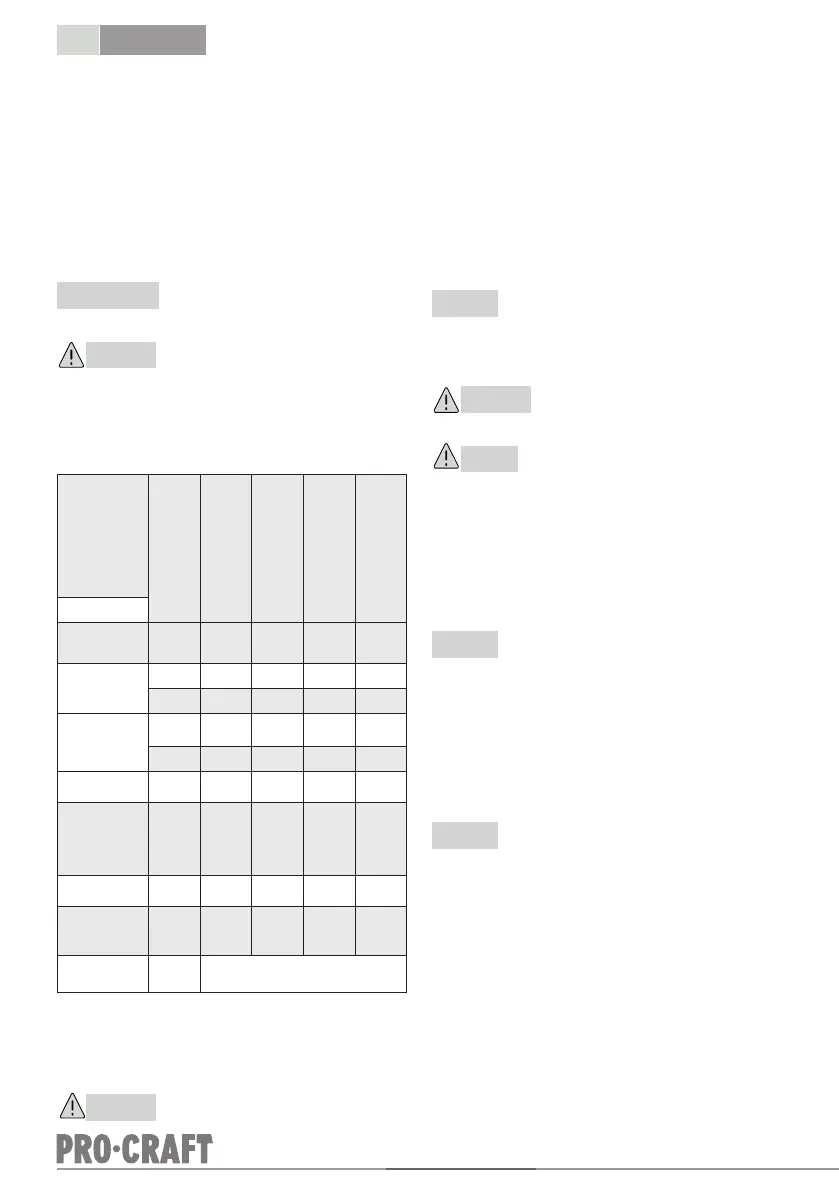

Maintenance schedule

REGULAR SERVICE

PERIOD

Performed at every

indicated month

or operating hour

interval whichever

comes first

Each use First

month or

20 Hrs

Every 3

months or

50 Hrs

Every 6

months or

100 Hrs

Every year

or 300

Hrs

ITEM

Engine Oil Check

level

О

Air cleaner

Change

О О

Check

О

Sediment

cup

Clean

0 (1)

Clean

О

Spark plug

Check-

Clean

О

Spark

arrester

(optional

parts)

Clean

О

Valve cleaner

Check-

Adjust

Fuel tank and

strainer

Clean

Fuel line

Check

Every 2 years (replace if necessary (2)

использовании

1. Service more frequently when used in dusty areas.

2. These items should be serviced by an authorized generator dealer unless

the owner has proper tools and is mechanically proficient.

3. For professional commercial use, log hours of operation to determine

proper maintenance intervals

WARNING

Improper maintenance, or failure to correct a problem before operation,

can cause a malfunction in which you can be seriously hurt or killed.

Always follow the inspection and maintenance recommendations and

schedules in this owner’s manual.

The maintenance schedule applies to normal operating conditions. If you

operate your generator under severe conditions, such as sustained high-

load or high-temperature operation, or use it in unusually wet or dusty

conditions, consult your servicing dealer for recommendations applicable

to your individual needs and use.

Engine oil change:

Drain the oil while the engine is warm to assure complete and rapid

draining.

1. Remove the drain plug and sealing washer4, oil filler cap, and drain the

oil.

2. Reinstall the drain plug and sealing washer. Tighten the plug securely.

3. Refill with the recommended oil and check the oil level.

(Pic. 10*)

Air cleaner service:

A dirty air cleaner will restrict air flow to the carburetor. To prevent

carburetor malfunction, service the air cleaner regularly. Service more

frequently when operating the generator in extremely dusty areas.

WARNING

Using gasoline or flammable solvent to clean the filter element can cause a

fire or explosion. Use only soapy water or nonflammable solvent.

NOTICE

Never run the generator without the air cleaner. Rapid engine wear will

result.

1. Unsnap the air cleaner cover dips, remove the air cleaner cover, and

remove the element.

2. Wash the element in a solution of household Detergent, and warm water,

then rinse thoroughly; or wash in nonflammable or high flash point solvent.

Allow element to dry thoroughly.

3. Soak the element in clean engine oil and squeeze out the excess oil.

The engine will smoke during initial start-up if too much oil is left in the

element.

4. Reinstall the air cleaner element and the cover.

(Pic. 11*)

Fuel Sediment Cup Cleaning:

The sediment cup prevents dirty water which may be in the fuel tank from

entering the carburetor. If the engine has not been run for a long time, the

sediment cup should be cleaned.

1. Turn the fuel valve to OFF position.

2. Remove the sediment cup, and O-ring.

3. Clean the sediment cup and O-ring in nonflammable or high flash point

solvent.

4. Reinstall O-ring and sediment cup.

5. Turn the fuel valve ON and check for leaks.

(Pic. 12*)

Spark Plug Service:

Recommended spark plugs: F5T or F6TC or F7TJC or other equivalents

To ensure proper engine operation, the spark plug must be properly gapped

and free of deposits.

If the engine has been running, the muffler will be very hot. Be careful not

to touch the muffler.

1. Remove the spark plug cap.

2. Clean any dirt from around the spark plug base.

3. Use the wrench supplied in the tool kit to remove the spark plug.

4. Visually inspect the spark plug. Discard it if the insulator is cracked or

chipped. Clean the spark plug with a wire brush if it is to be reused.

5. Measure the plug gap with a feeler gauge. Correct as necessary by

carefully banding side electrode.

The gap should be: 0.70-0.60 mm (0.026-0.031 in).

6. Check that the spark plug washer is in good condition, and thread the

spark plug in by hand to prevent cross-threading.

7. After the spark plug is seated, tighten with a spark plug wrench to

compress the washer.

Loading...

Loading...