20

OPERATING INSTRUCTIONS

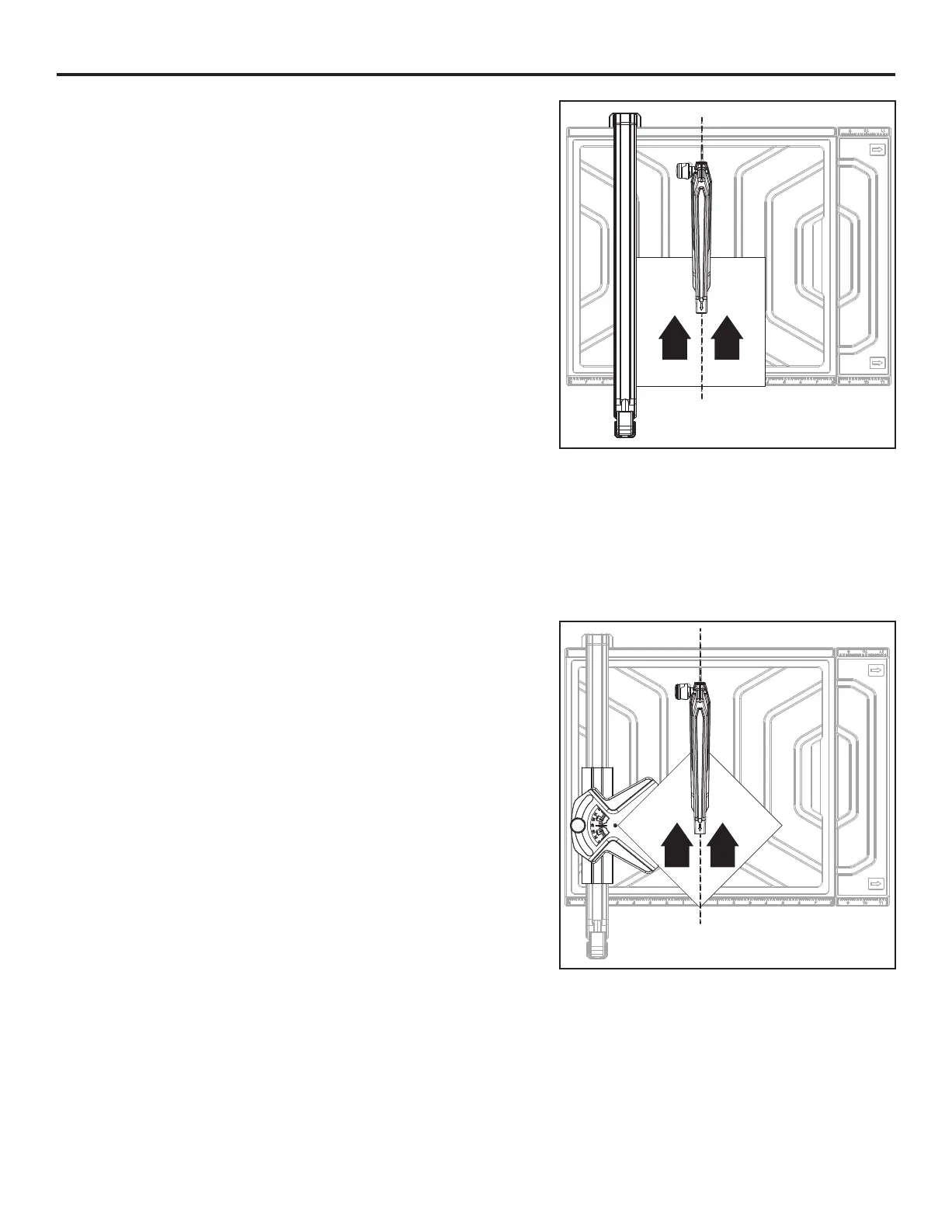

Making a Cross Cut

Cross cuts are straight 90° cuts. The material is fed into

the saw at a 90° angle to the wheel.

• Using a marker or grease pencil, mark the area to be

cut on material.

• Remove the miter gauge.

• Position the rip guide (E) the desired distance from the

wheel for the cut and securely locking lever.

• Place the material on the table, firmly against the rip

guide.

• Make sure the material is clear of the cutting wheel

before turning on the saw.

• Turn the on/off switch to the ON position.

• Let the cutting wheel build up to full speed and wait for

the wheel to get wet before moving the material into

the wheel.

• Hold the material firmly against the rip guide and feed

the material into the cutting wheel.

• When the cut is made, turn the saw OFF. Wait for the

cutting wheel to come to a complete stop before

removing any part of the material.

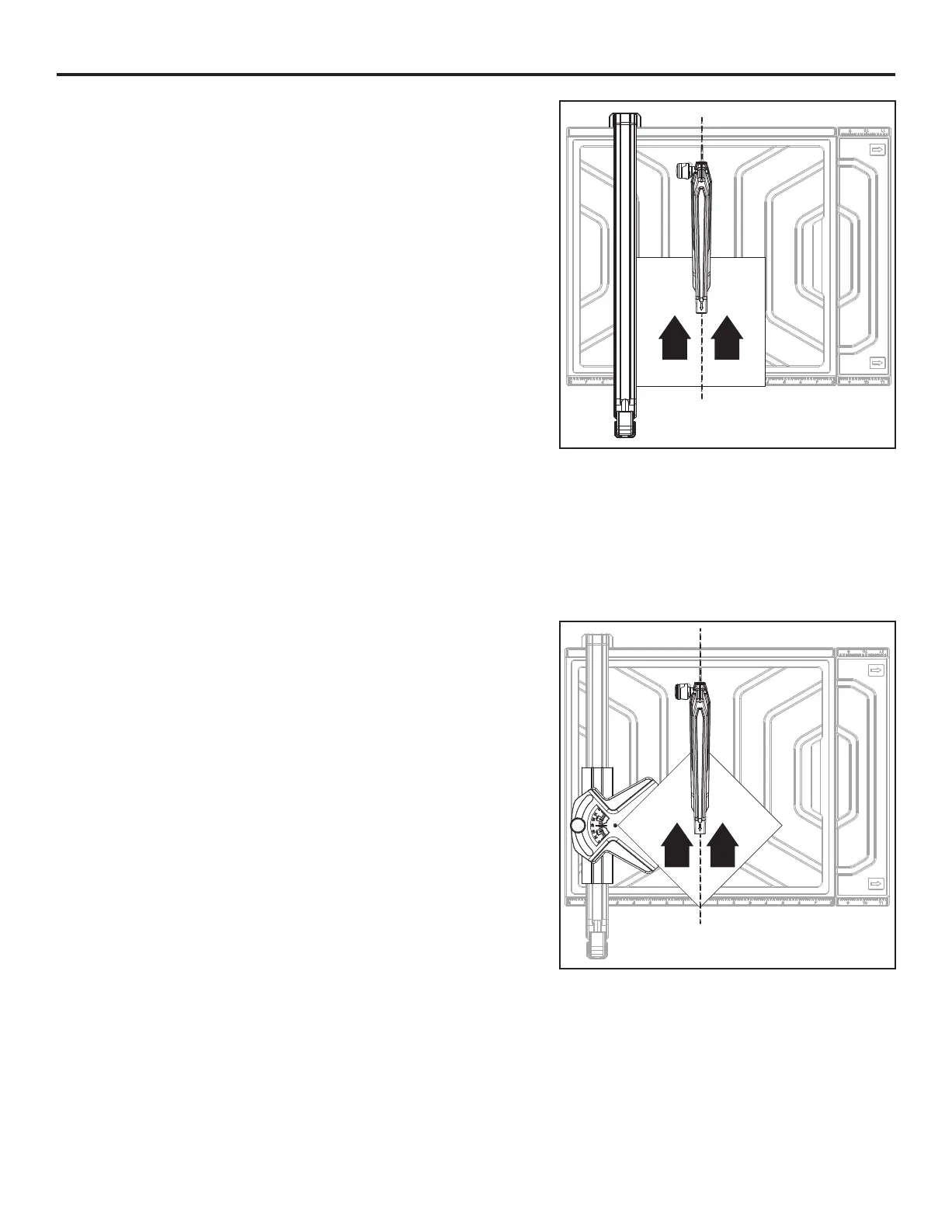

Making a Diagonal Cut

45° Diagonal cuts are also referred to as “long point-to-

long point cuts”.

• Using a marker or grease pencil, mark the area to be

cut on material.

• Install the miter guide (B).

• Adjust miter guide to 45° using angle scale and tighten

securely with miter guide knob.

• Place the material on the table and firmly against the

miter guide.

• Make sure the material is clear of the cutting wheel

before turning on the saw.

• Turn the on/off switch to the ON position.

• Let the cutting wheel build up to full speed and wait for

the wheel to get wet before moving the material into the

wheel.

• Hold the material firmly against the miter guide and

table fence. Feed the material into the cutting wheel.

• When the cut is made, turn the saw OFF. Wait for the

cutting wheel to come to a complete stop before

removing any part of the material.

Loading...

Loading...