SAFETY WARNINGS & GENERAL INFORMATION

The Heatsource HS2000 is intended for use only as a space heater in caravans, motor

caravans, mobile homes/units.

Installation and servicing of this appliance must only be carried out by persons registered

with the Gas Safety Register (GB), or the relevant national organisation, in accordance

with the relevant regulatory and safety requirements.

Heater installations must comply with the current European standards for Motorhomes /

Caravans.

This heater is not suitable for installation on the outside of the vehicle.

The heater must not be operated when refueling: the vehicle, towing vehicle, other

appliances or when the vehicle is in a confined space, such as a garage.

The exhaust gas outlet must not be fitted on the entry door nor in any position where

combustion products may enter the interior.

The heater is designed to operate on Propane or Butane. Under no circumstances should

an adjustable regulator be used.

Do not allow materials to come into direct contact with the heater. Under no

circumstances must the re-circulation air inlet be covered or obstructed at any time.

The Heatsource HS2000 heater has a type C

53

flue, and has been tested and passed the

relevant sections of the following standards:

Gas Appliance Regulation (EU) 2016/426 on the approximation of the laws of the Member States

relating to appliances burning gaseous fuels.

Low Voltage Directive 2014/35/EU on the harmonization of the laws of the Member States relating to

electrical equipment designed for use within certain voltage limits.

Electromagnetic Compatibility Directive 2014/30/EU, on the approximation of the laws of the Member

States relating to electromagnetic compatibility.

Automotive EMC Directive 2004/104/EC (latest amendment 2009/19/EC) as per regulation 10.05

CE mark first affixed: November 2009

This product complies with all relevant European directives and standards. Please contact Propex if

further details are required.

A data label is situated adjacent to the gas inlet.

The gas supply line should be checked regularly for damage or leaks and tested under

pressure with a proprietary leak tester. NEVER TEST FOR GAS LEAKS WITH NAKED

FLAME. If a gas leak is detected or smelt, turn off gas at the bottle immediately and

ventilate the area. Contact a registered installer (see a) above) to rectify the problem.

IMPORTANT: Do not direct the combustion products outlet terminal

(exhaust flue) towards the combustion air inlet terminal.

For this appliance in Europe the standard is BS EN 1949:2011 (Specification for the

installation of LPG systems for habitable purposes in leisure accommodation vehicles and

in other road vehicles).

- 2 -

- 7 -

a)

b)

c)

d)

e)

f)

g)

h)

i)

j)

k)

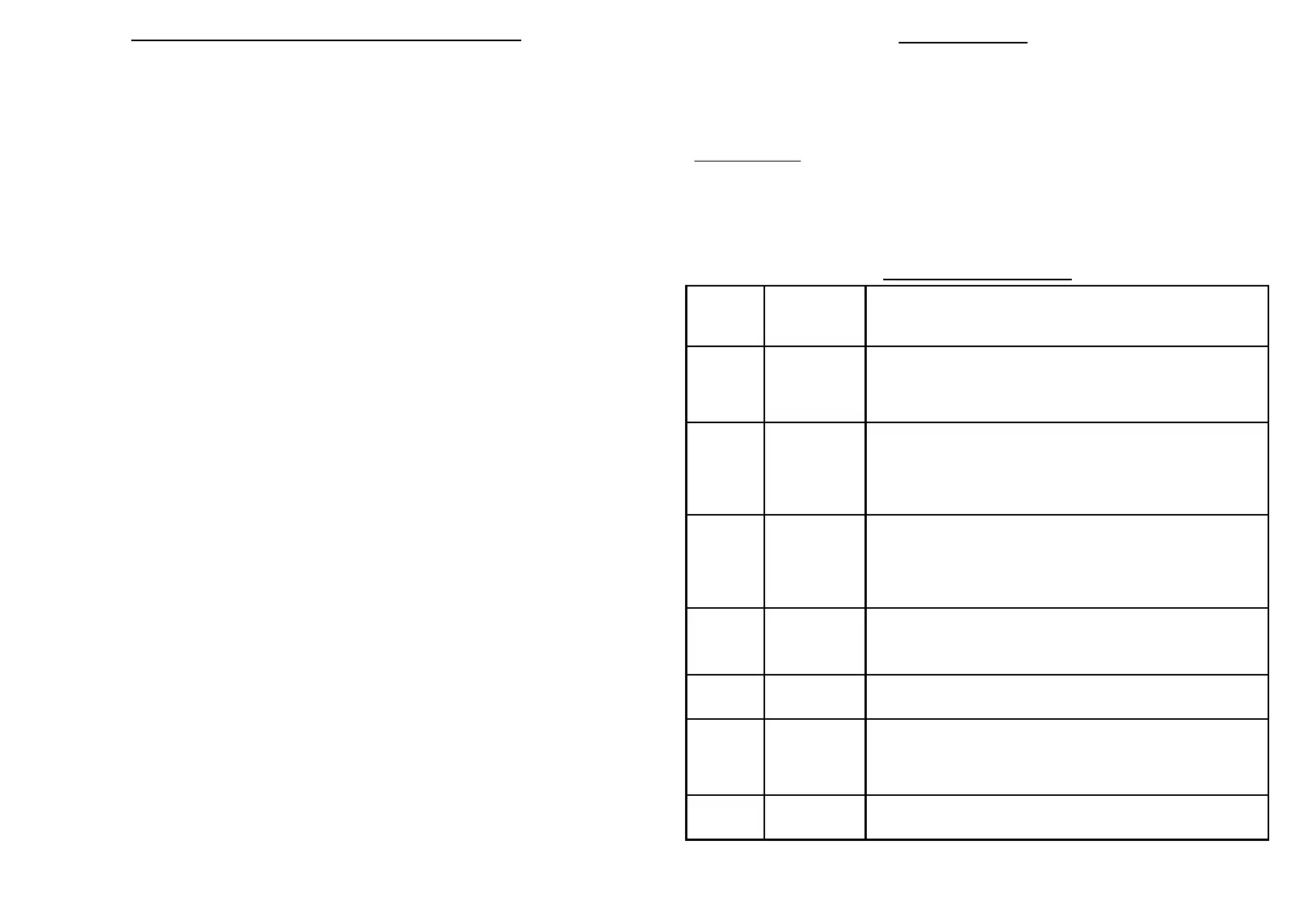

FAULT FINDING

The Heatsource HS2000 is equipped with an electronic diagnostic system which will detect

fault conditions ranging from poor gas or electricity supply to internal heater malfunctions. In

the event of a failure the red light on the thermostat (or timer control) will flash a certain

amount of times, pause, and repeat until switched off. Count the amount of flashes and refer

to the table below.

Overheat Cut-Out.

The HS2000 is equipped with an automatic resetting thermal cut-out (in addition to the

electronic cut-out). If the heater reaches an unusually high temperature during operation the

cut-out will disengage the gas solenoid valve. The operation of this cut-out could be caused by

either a restricted hot air outlet or air inlet, or the heater being switched off by a battery

isolating switch depriving it of its purge cycle, the fault code is 2 flashes.

FAULT FINDING TABLE

Number

of

flashes

Fault Remedy

1

Flame

failure

Check gas supply making sure there is gas in the bottle and no

blockage in the gas line. Ensure propane is used at

temperatures below +5°C.

Clear lockout as described on page 8.

2

Overheat

fault

Check the air ducts and vents are not blocked or restricted.

Propex recommends that you wait at least 5 to 10 minutes to

allow the heater to cool before clearing lockout as described on

page 8.

3

Low/ high

voltage

Minimum operating voltage is 10v and max operating voltage is

15v (for 12v heaters) when measured at the heater. Check

battery voltage. If above 10v, check connections between

heater and battery. Check alternator or external battery

charging. Clear lockout as described on page 8.

4

Combustion

air fault

Check combustion air inlet flue and exhaust flue for blockages.

Clear lockout as described on page 8.

5

Other /

internal fault

Attempt to clear lockout as described on page 8. If this fails.

contact Propex.

Solid General

Two faults have occurred at the same time OR more than 5

lockout clearing attempts have been unsuccessful. Clear

lockout as described on page 8.

No

flashing

PCB not

powered up

Check the supply to the heater as above. Otherwise contact

Propex

Loading...

Loading...