1

After 3 to 5 minutes of cooling, the motor is ready

to be operated again and can be fully loaded.

ATTENTION! Do not ever operate the

machine when a defect of electronics has

occurred; an unwanted increase of revolu-

tions could occur. You may recognize a

defect of electronics by the fact that gradual

start-up is out of function or the number of

revolutions is impossible to be set.

Milling tools

Choice of cutter and grinding head

According to use and type of application, there

are various types of cutter heads. To achieve

optimal work results, use suitable grinding heads.

Data in the Chart showing speed pre-selection

options are recommended values only; practice

testing should be always performed!

Cutter head

Grinding head

Installation

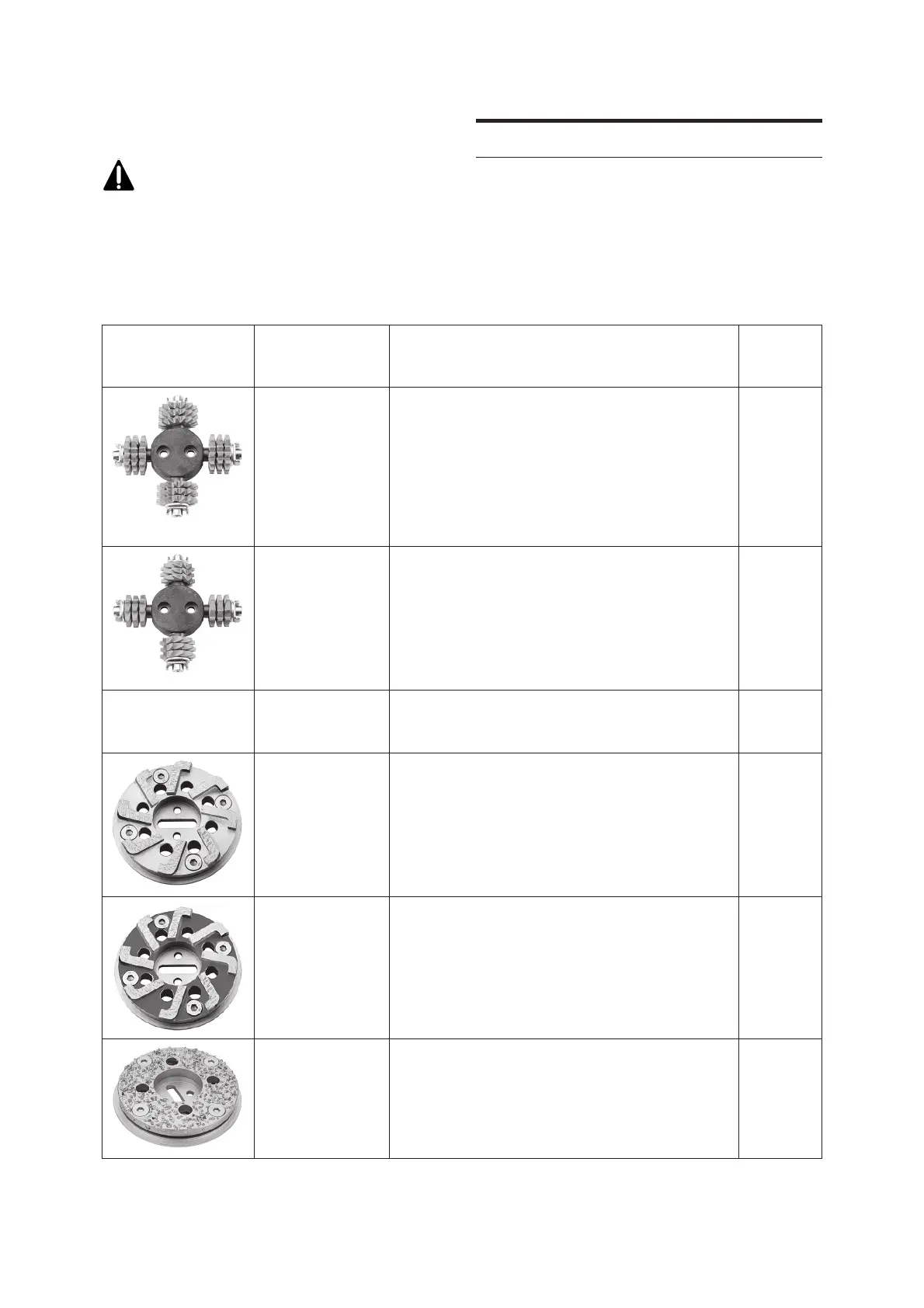

Cutter head

“Flat Shape” with

12 hard-metal

cutter wheels

FZ-RGP 80

Cutter head

“Pointed Shape”

with 12 hard-metal

cutter wheels

SZ-RGP 80

Installation

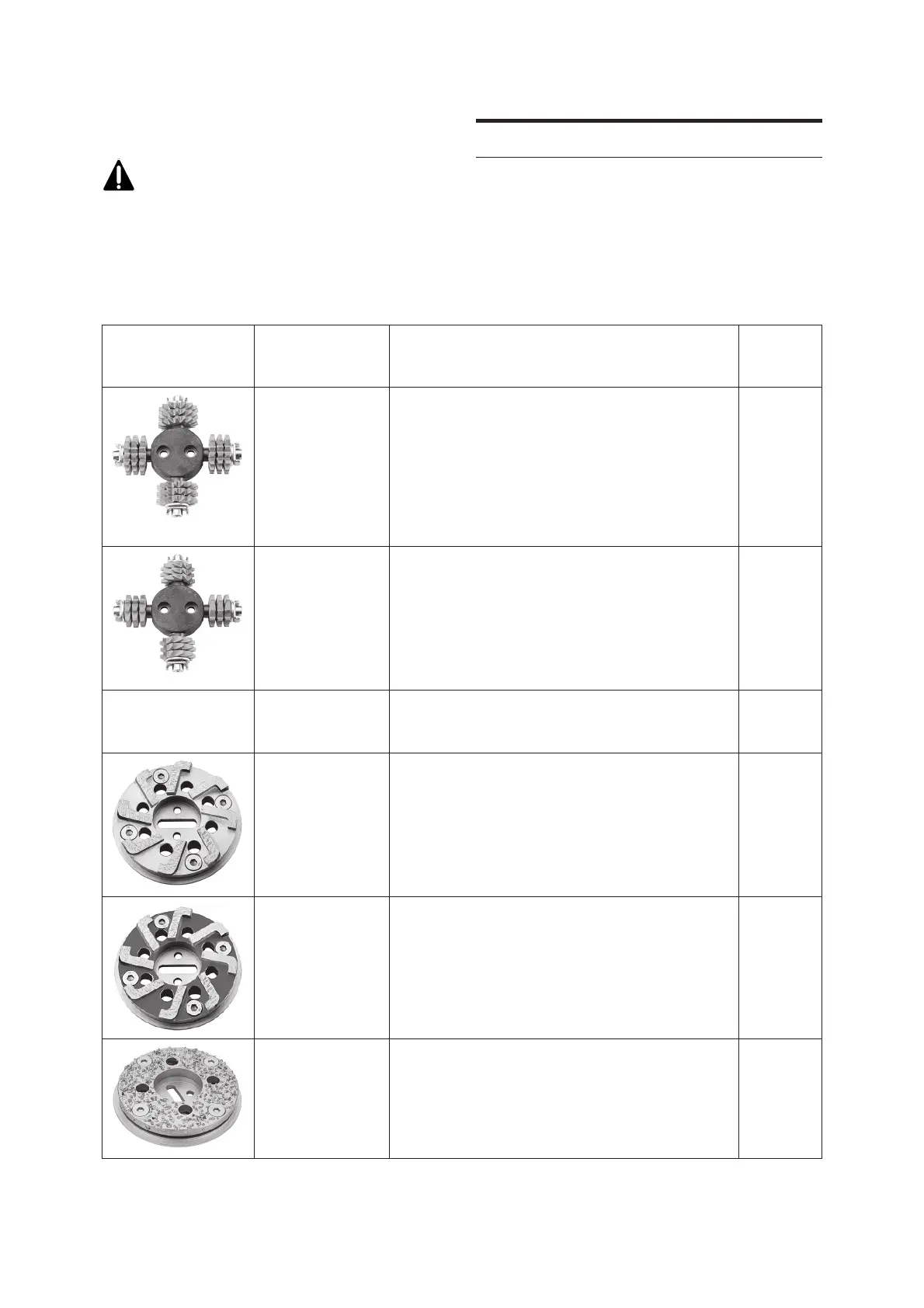

Diamond grinding

head: grinding

wheel with 8

segments provided

with diamond grits

DIA HARD-RGP 80

Diamond grinding

head: grinding

wheel with 8

segments provided

with diamond grits

DIA ABRASIVE-

RGP 80

Hard-metal grinding

head: grinding

wheel provided with

hard-metal grits

HW GROB-RGP 80

Application

– Removing of butter ball (mineral plaster)

– Removing of elastic protective coats on walls and

flooring

– Removing of foam base and glue remnants (carpet

remnants)

– Removing of floor tile glue remnants

– Removing of bitumen and concrete protective coats

– Removing of latex paints or oil paints on gypsum

surface

– Removing of hard plaster (cement plaster)

– Removing of bumps and excessive material after

boarding – fresh concrete work

– Removing of foam base and glue remnants (and

carpet remnants)

– Removing of floor tile glue remnants

– Removing of plaster made of synthetic resin (made

on thermal insulation)

Application

– Removing of bumps and excessive material –

screed floor cover

– Grinding and cleaning weather-worn parts of

concrete constructions

– Removing of bumps – old concrete

– Removing of bumps and excessive material –

screed floor cover

– Grinding and cleaning – fresh concrete

– Grinding – abrasive materials

– Removing of elastic protective coats on walls and

flooring

– Reduction of gypsum and cellular concrete

– Removing of impurities – concrete floors

– Removing of latex or oil paints – gypsum surface

– Rough working

Electronic

adjusting

wheel

4. – 6.

4. – 6.

Electronic

adjusting

wheel

3. – 4.

3. – 4.

1. – 2.

Loading...

Loading...