6

OPPERATION

OPERATION

1.

Situate the compressor as far away as possible from sandblasting area to minimize dust intake.

2. The air supply must be clean and free of moisture and oil.

3. Use a compressor that can supply enough air per specifications. Insufficient air pressure will

prevent the tool from operating correctly.

4. Always test the sandblaster on a hidden surface to make sure damage will not occur.

5. Always filter the abrasive material to remove any clumping or debris and prevent clogging.

6. Do not try to spray thick liquids or large grain sized abrasives.

7. Use the lowest effective pressure on soft surfaces to prevent pitting.

8. With the air hose and rubber hose connected, and wearing proper safety equipment, aim

sandblaster gun at surface and pull trigger.

9. Whenever the nozzle is removed, cleaned, or replaced use a brush to clean the threads and

replace the o-ring.

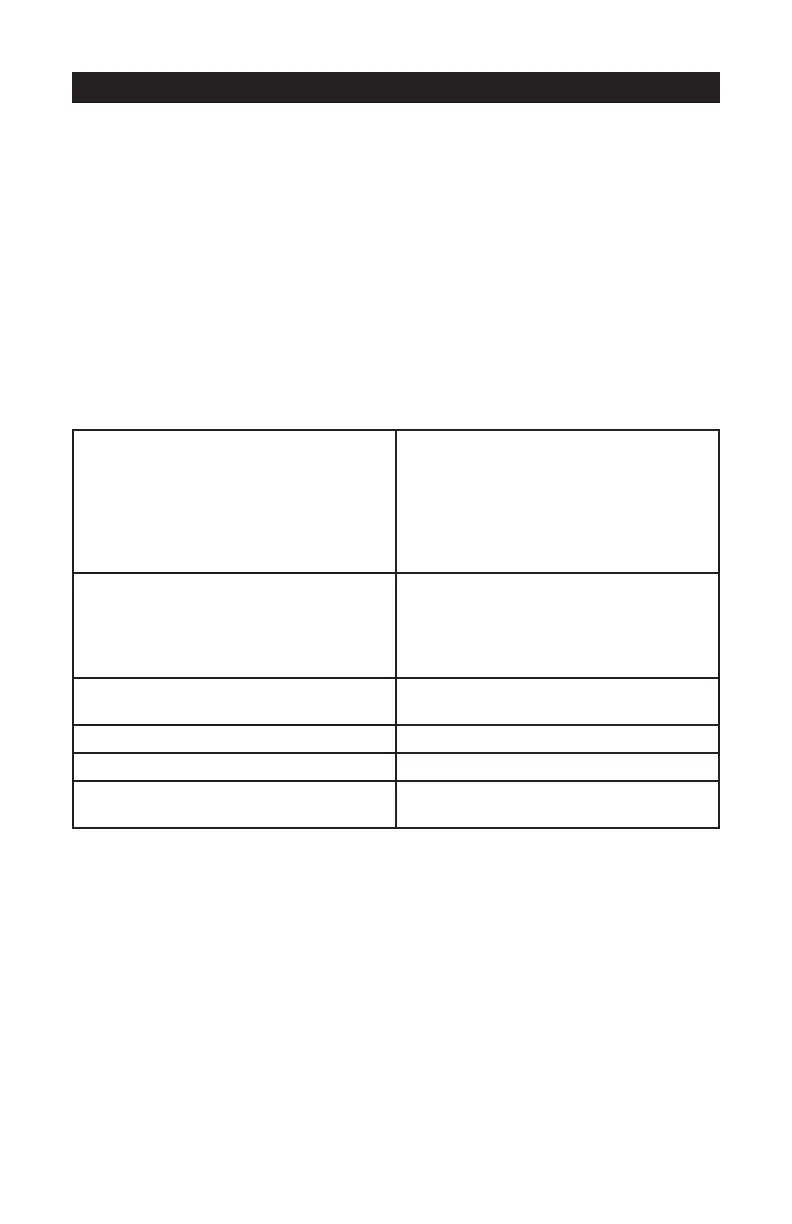

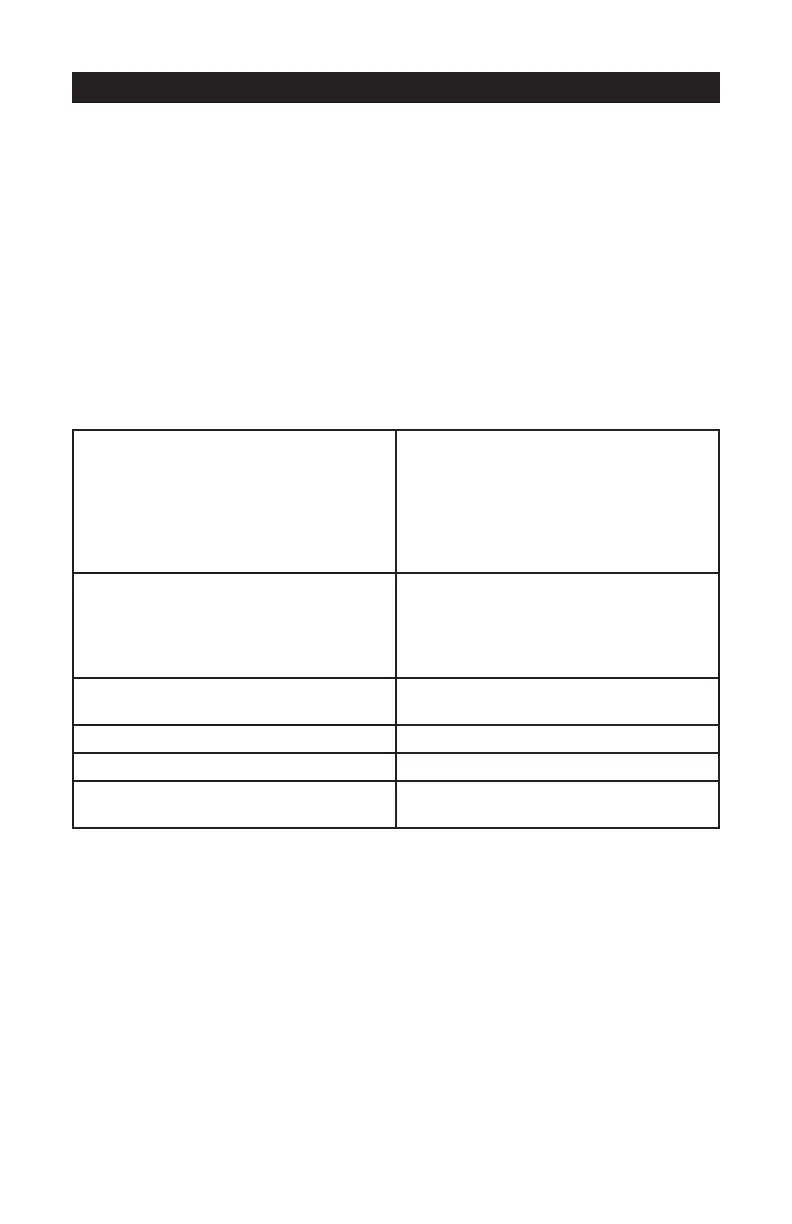

TYPE OF ABRASIVE (SIEVE/SIZE)

APPLICATION

Sand (20-40)

General purpose use. Removing light rust

and paint from metal, wood or other

surfaces; wood finishing; metal cleaning;

glass and stone etching; hole drilling in

glass, brick or cement block; light stone

cleaning; exterior automotive parts

cleaning and water deposit removal

Sand (50-100)

Used for a fine polish finish or antique

wood finish, brass and silver polishing,

automotive parts cleaning and polishing,

sheet metal surface polishing, and fine

glass etching

Aluminum oxide

Heavy rust removal and rough surface

paint removal

Corn cob meal Wood and glass cleaning (fine)

Walnut or pecan shells (ground) Wood and glass cleaning (coarse)

Wood and glass cleaning (coarse)

Removal of flash, burrs and paint from

metal or glass without abrading work

* Note: Abrasive media that has not been cleaned and screened could contain material that will clog the gun nozzle and

should be avoided

Loading...

Loading...