1. Remove the air inlet protective cap from the air inlet.

2. Mount a male plug by hand into the air inlet.

NOTE: Use thread sealant tape on the male plug and tighten it with a wrench for

airtight connection. Do not overtighten.

3. Place 2 - 3 drops of air tool oil into the male plug before each use.

4. Choose the correct impact socket (not provided) as needed and mount it onto the anvil.

5. If necessary, use an extension bar (not provided) and then mount impact socket onto

the bar.

6. Connect air supply hose to the male plug.

7. Set the working pressure at 90psi/6.3bar for best tool performance.

NOTE: Working pressure refers to the air line pressure set to tool when tool is under

working conditions.

OPERATION

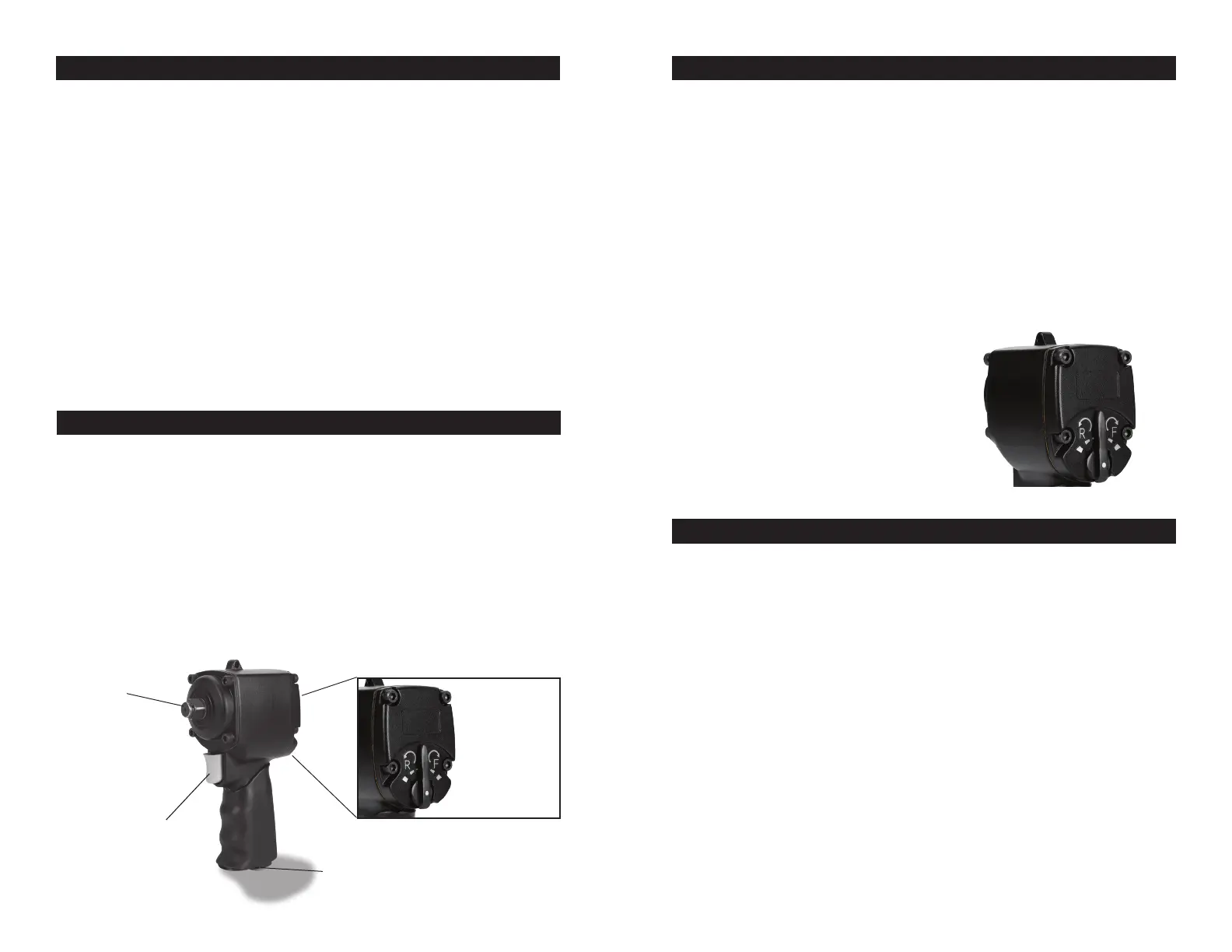

1. How to install/tighten threaded fasteners.

Turn the switch forward and have the arrow on the switch pointing at either of the three

dots on the back housing as shown. Press the variable speed trigger to apply the

needed force for your application. The tool anvil runs clockwise.

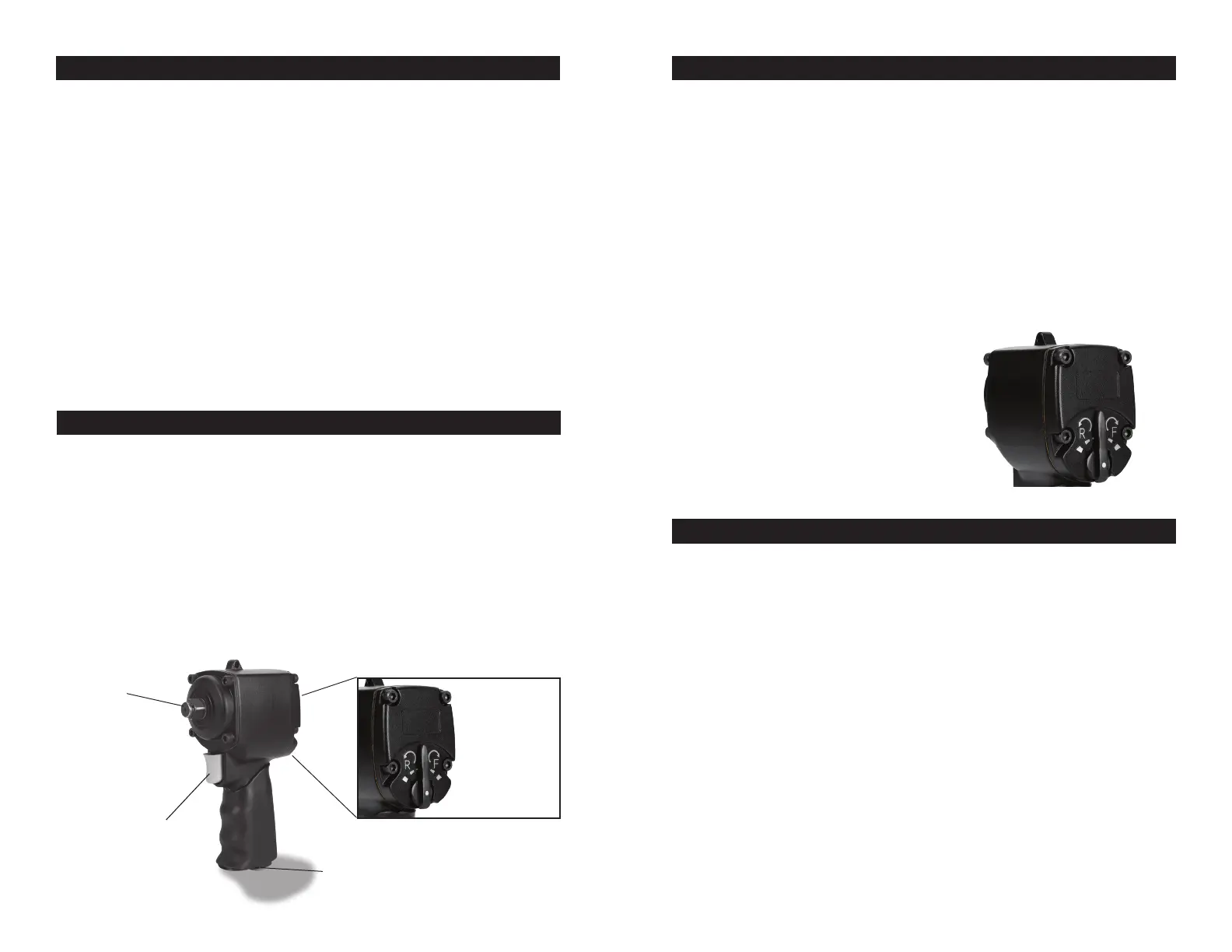

2. How to remove/loosen threaded fasteners.

Turn the switch backward and have the arrow on the switch pointing at the large dot on

the back housing as shown in the picture above. Press the trigger. The tool anvil runs

counterclockwise.

NOTE: This tool features a power regulator valve. Turn the switch slowly forward until

desired output is achieved. The three dashes (small, medium, large) do not denote a

specific power output but are only for reference. "Setting 1" (small dash) is the least

amount of power, which is suitable for just mounting threaded fasteners on workpiece

while "Setting 3" (large dash) is the greatest amount of power, which is for tightening

threaded fasteners on workpiece. This tool operates in maximum power in reverse,

which releases threaded fasteners from workpiece with ease. Choose the correct speed

level needed on workpiece when mounting or releasing threaded fasteners.

ASSEMBLY

Air Inlet

Forward/Reverse

Switch

Anvil

Trigger

NOTE: Make sure that this tool has the correct

torque to tighten/release threaded fasteners.

The torque applied to threaded fasteners can be

found in their instructions or manuals.

Overtightening of your fasteners will strip

threads or break bolts resulting in costly or time

consuming repairs.

4

CARE & MAINTENANCE

An in-line oiler is recommended to be installed on air supply line as it increases tool life

and keeps the tool in sustained operation. The in-line oiler should be regularly checked

and lled with air-tool oil. Proper adjustment of the in-line oiler is performed by placing a

sheet of paper next to the tool's exhaust ports and holding the throttle open approximately

30 seconds. The in-line oiler is properly set when a light stain of oil collects on

the paper. Excessive amounts of oil should be avoided.

In the event that it becomes necessary to store the tool for an extended period of time, it

should receive a generous amount of lubrication at that time. The tool should be run for

approximately 30 seconds to ensure oil has been evenly distributed throughout the tool.

The tool should be stored in a clean and dry environment.

Recommended lubricants: use air-tool oil or any other high-grade turbine oil containing moisture

absorbent, rust inhibitors, metal wetting agents and an EP (extreme pressure) additive.

Clean the tool all over with a cotton rag after each use. Keep the tool in a dry and safe

place out of reach of children.

5

1. Use only clean, dry, regulated compressed air as the power source.

2. Air compressors used with the tool must comply with the appropriate European

Community Safety Directives.

3. Make sure that the air compressor being used for the tool operation supplies the

correct output (CFM).

4. Have the tool in "off" position when connecting the tool to the air supply.

5. Use normal 90psi working pressure for the tool. High pressure and unclean air will

shorten the tool life due to the faster wear and also may create a safety hazard.

6. Drain water from the air compressor tank daily, as well as any condensation in the air

lines. Water in the air line may enter the tool and cause damage to the tool mechanisms

at operation.

7. Clean the tool air inlet screen filter for blockage weekly. Clean if necessary.

8. Usually a 3/8" (inner diameter) air hose is recommended for air supply and airflow to

get the optimum performance of tool.

9. A long air hose (usually over 8 meters) may cause up to 15psi drop in pressure, so

you need to set the output pressure of the air compressor higher to maintain the

required working pressure at the tool.

10. Use proper hoses and fittings. We do not suggest connecting quick change couplings

directly to the tool since they may cause failure due to tool vibration at operation.

Instead, add a lead hose and connect coupling between air supply and hose whip.

11.

Check hoses for wear before each use. Make certain that all connections are in security.

AIR SOURCE

Loading...

Loading...