PAGE 11

GENERAL:

In most cases, when the hydraulic winch does not perform satisfactorily, the cause of malfunction is found

somewhere in the hydraulic circuit. Before the winch is removed from its mounting and disassembled, all of the

hydraulic circuit components should be checked for proper function.

IMPORTANT:

The hydraulic oil volume relates to the line speed or rpm of the winch.

Therefore, if the winch does not produce the specified maximum rated line speed or drum rpm, a loss of

hydraulic flow somewhere in the hydraulic circuit system can be analysed. If this condition exists, install a flow

meter into the hydraulic circuit to check the volume supplied to the pressure port of the hydraulic winch motor

when the winch control is completely opened. The flow meter should indicate the maximum operating volume.

If this test indicates a loss of hydraulic flow, check the hydraulic pump, the relief valve and the control valve.

If the pump is driven by V-belts, check for belt slippage.

The hydraulic pressure relates to the line pull or lifting capacity of the winch.

If the winch will not lift the specified maximum line pull, install a pressure gauge into the pressure line leading

to the hoisting port on the hydraulic winch motor. Stall the winch to prevent rotation of the drum and then open

the control valve. Check the hydraulic pressure reading of the installed pressure gauge. If the pressure reads

below the specified maximum operating pressure, look for trouble in the hydraulic pump, the relief valve and

the control valve. If the pump is driven by V-belts, check for belt slippage. When checking oil pressure and

volume in the hydraulic circuit, make certain that the hydraulic reservoir is filled to the top level and the hydraulic

pump is running at maximum operating rpm.

Only if the hydraulic system has been checked and found to be in order, use the following indications for

probable causes of failure in the winch:

251 REV.950201

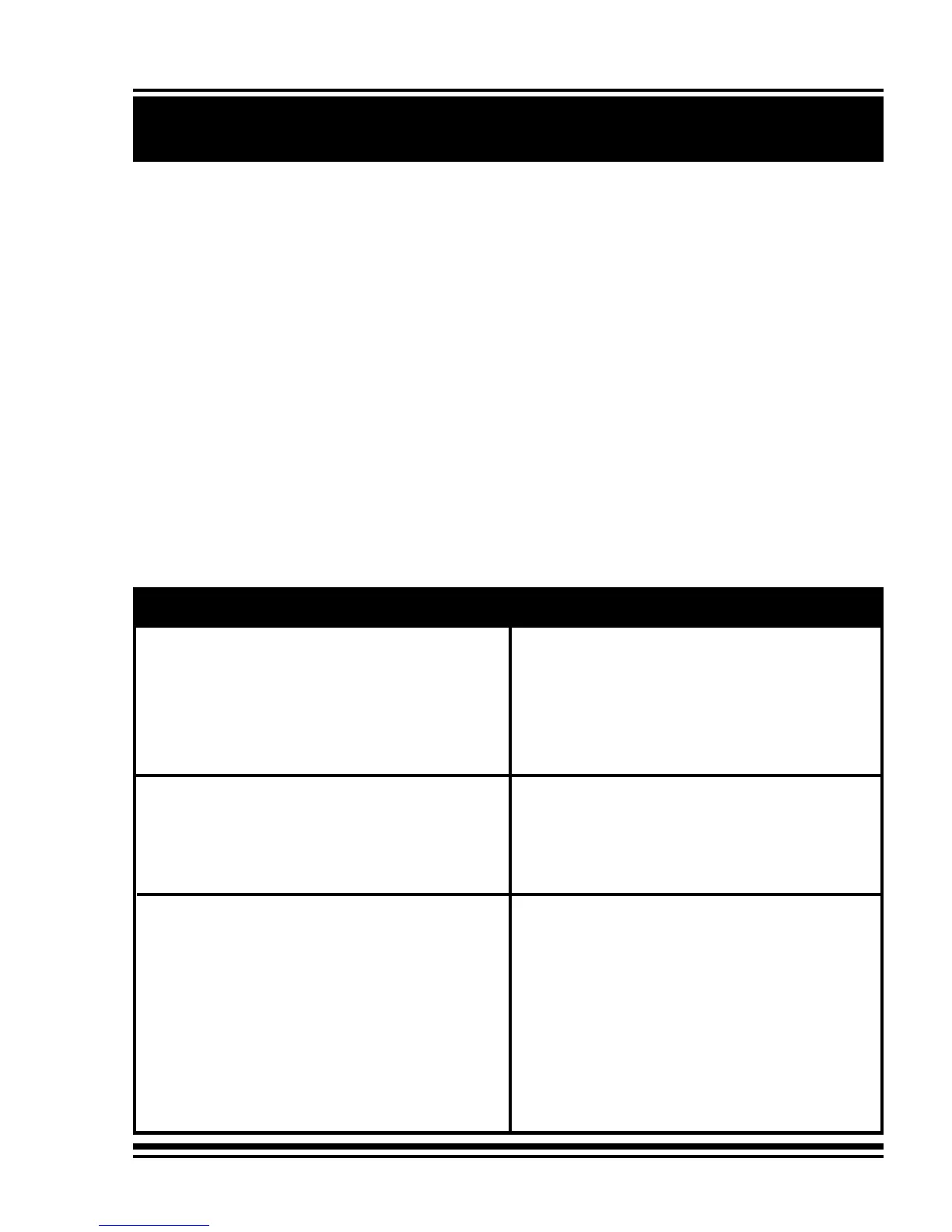

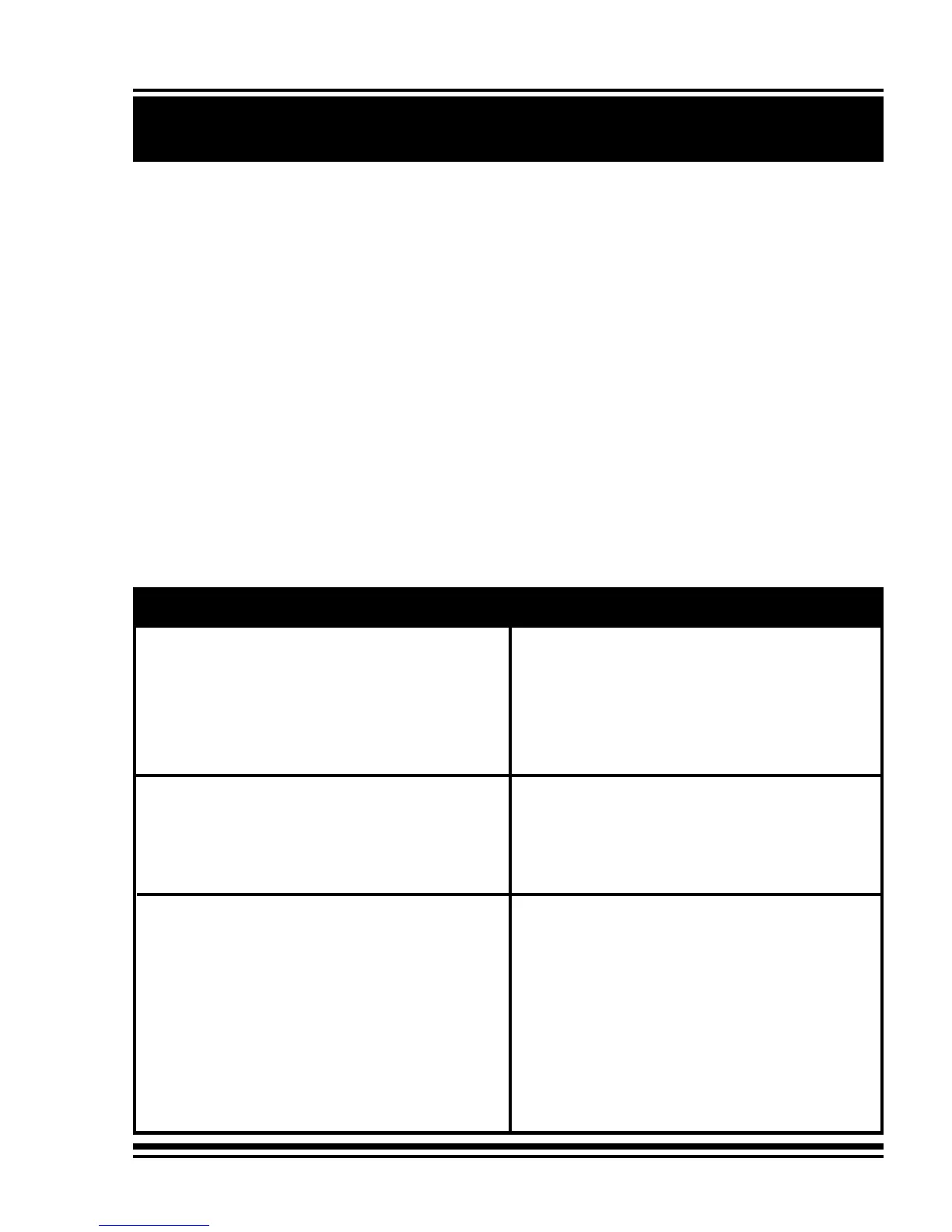

TROUBLE SHOOTING

FAILURE

PROBABLE CAUSE

Winch will not produce line pull at maximum

pressure as listed in SPECIFICATIONS.

Winch will not produce line speed at maximum

volume as listed in SPECIFICATIONS.

Winch will not reverse.

a) Winch is mounted to an uneven surface (see

INSTALLATION INSTRUCTIONS).

b) Cable sheaves or block purchase operated with the

winch are not turning freely.

c) Damage or wear in the hydraulic motor.

d) Excessive back pressure in the hydraulic system.

e) Relief valve may be set too low. (See SPECIFICATIONS

for maximum operating pressure.)

a) Winch is mounted to an uneven surface (see

INSTALLATION INSTRUCTIONS).

b) Cable sheaves or block purchase operated with the

winch are not turning freely.

c) Damage or wear in the hydraulic motor

d) Excessive back pressure in the hydraulic circuit.

a) Leakage out of the brake piston prevents the brake

from being released against the brake springs. This is

caused by damaged O-ring seals on the brake piston.

b) The O-ring seals, on the brake release channel between

the motor adaptor and the brake housing is damaged.

If this failure occurs there will be substantial leakage

from between the motor adaptor and brake housing.

c) Insufficient hydraulic pressure. (See SPECIFICATIONS

for minimum operating pressure.)

d) Winch is mounted to an uneven surface (see

INSTALLATION INSTRUCTIONS).

e) Hydraulic pressure is not reaching the brake piston

(plugged brake release orifice in the brake housing).

Loading...

Loading...