1. Cover the pump tubing/hose ends with tape if they are to be pulled through trenches or laid on the

ground. This is to prevent debris from entering the lines.

2. Blow out all water and particles from compressed air conduits (including downwell pump air supply lines)

and fluid lines for at least 10 seconds after the water and particles exit before connecting them to the

system.

3. Slip clamps over appropriate tubing/hose prior to connecting the tubing/hose to the pump barbs.

4. Push tubing/hose down flush with the fitting's nut if possible; cover at least three barbs if three or more

are present (Note: when installing tubing in freezing weather, tubing can be dipped in warm water for a

few seconds to soften the nylon).

Note: Submerging the pump before supplying it with air can also result in fluid entering the air supply line.This

fluid from the well can contain particles, which could interfere with operation of the pump's air valve.

9

Revision 3 - December, 2013Revision 3 - December, 2013

Chapter 5: Installation

9. Lower the pump to the desired depth in the well.

10. Secure the pump by tying off the pump support line or by placing the well cap (or flange) on the well.

Caution: Submerging the pump before supplying it with air will result in fluid entering the exhaust

tubing/hose. Those fluids will be discharged from the exhaust tubing/hose during the first few cycles

of the pump. If this discharge will not be confined to the well; i.e., if the air exhaust line is routed

7. Connect the pump air supply and liquid discharge lines to the appropriate surface lines/headers.

8. Turn on the air pressure to the pump (minimum of 0.5 psi per foot of vertical static head).

5. Attach pump support rope/cable to the pump. "See figure 7"

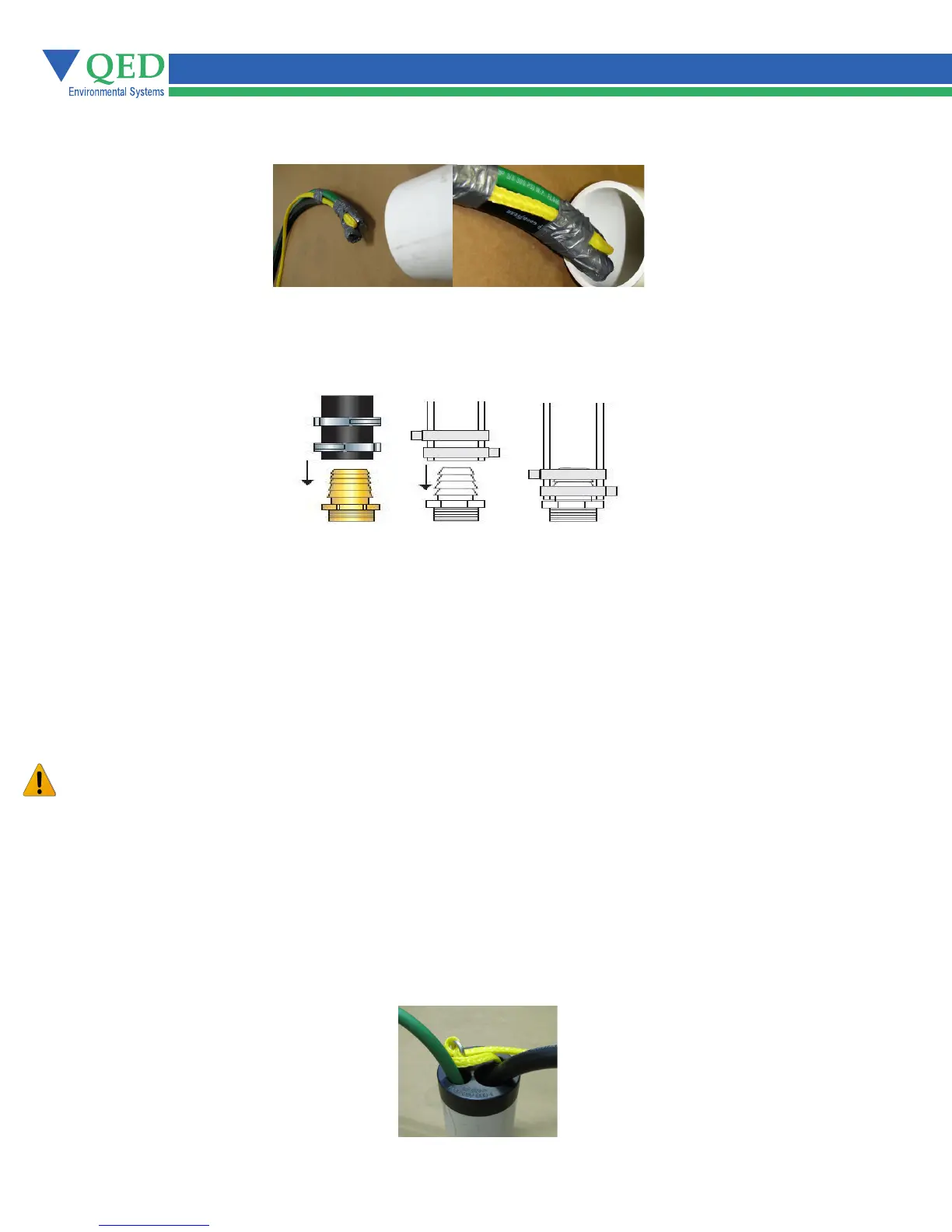

6. Attach pump air supply and liquid discharge lines to the well cap. "See Figure 6". Attach the air

exhaust line to the well cap if the pump air is to exhaust outside the well (Note: the liquid discharge line

is always the largest diameter of the three lines, and the air supply line is always the smallest diameter).

outside the well*, it is important to make sure that the air exhaust line is not directed such that

equipment/ personnel could be splashed by the discharged fluid when air is turned on to the pump.

Loading...

Loading...