EN

BTR185 INSTALLATION AND USE MANUAL - REV009A

40

BTR1857 - Notification

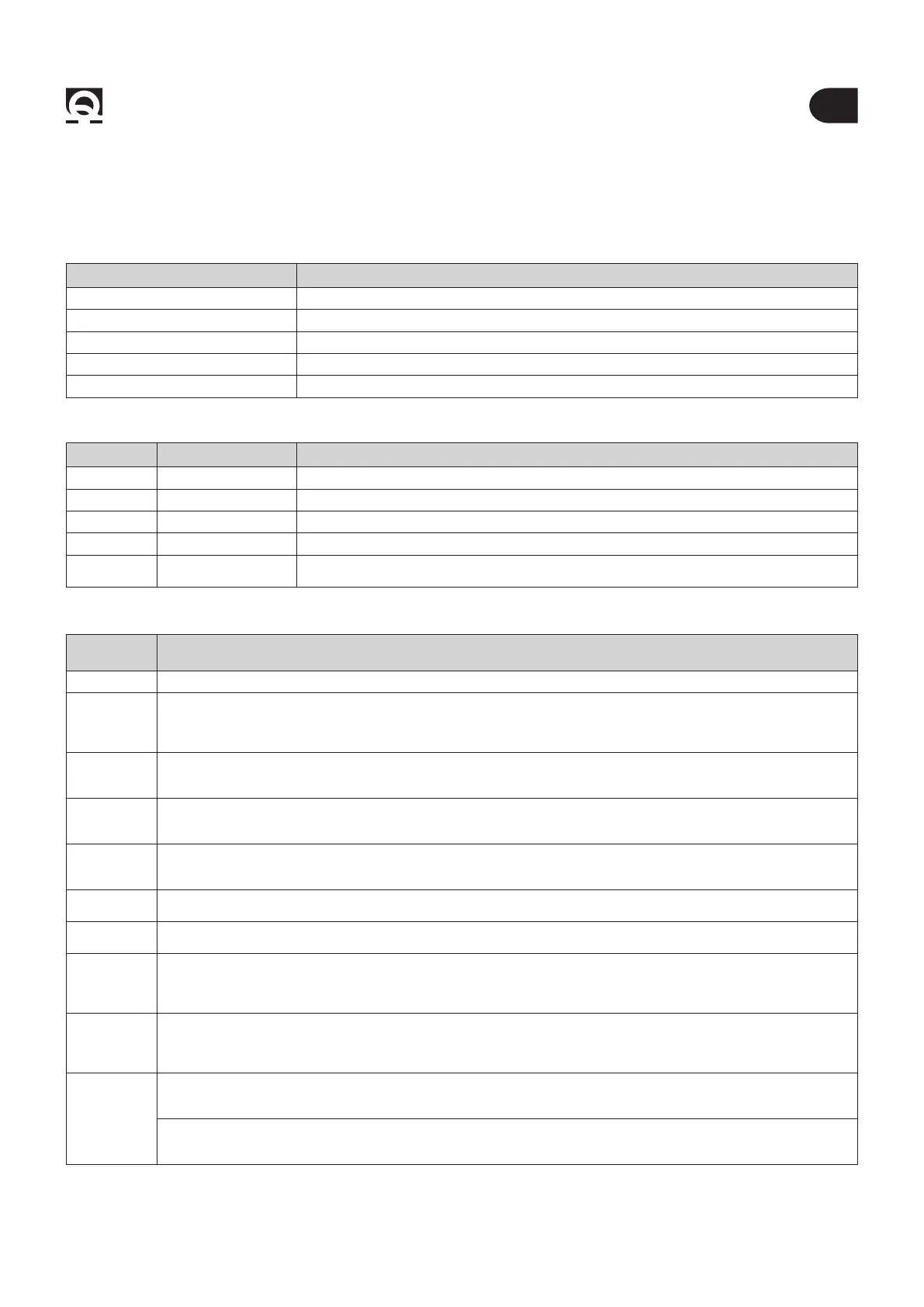

LED LA STATUS (BI-COLOUR)

LED POWER (GREEN)

LED STATUS DESCRIPTION

OFF Board not powered

SLOW FLASHING Powered board but disabled control

FAST FLASHING Powered board and actuator’s manual movement mode on

ON WITH SHORT SWITCHING OFF Powered board but disabled control and active link with the CAN control station

ON Powered board and enabled control (TCD or CAN station).

LED COLOUR LED STATUS DESCRIPTION

- OFF With powered board, actuator’s manual movement mode on and limit switch anomaly present

RED ON Retractable thruster closed (LSC limit switch enabled)

GREEN ON Retractable thruster open (LSO limit switch enabled)

ORANGE ON Retractable thruster neither open nor closed (LSC and LSO limit switches disabled)

ORANGE FLASHING

Retractable thruster neither open nor closed (LSC and LSO limit switches disabled) and linear actuator

moving.

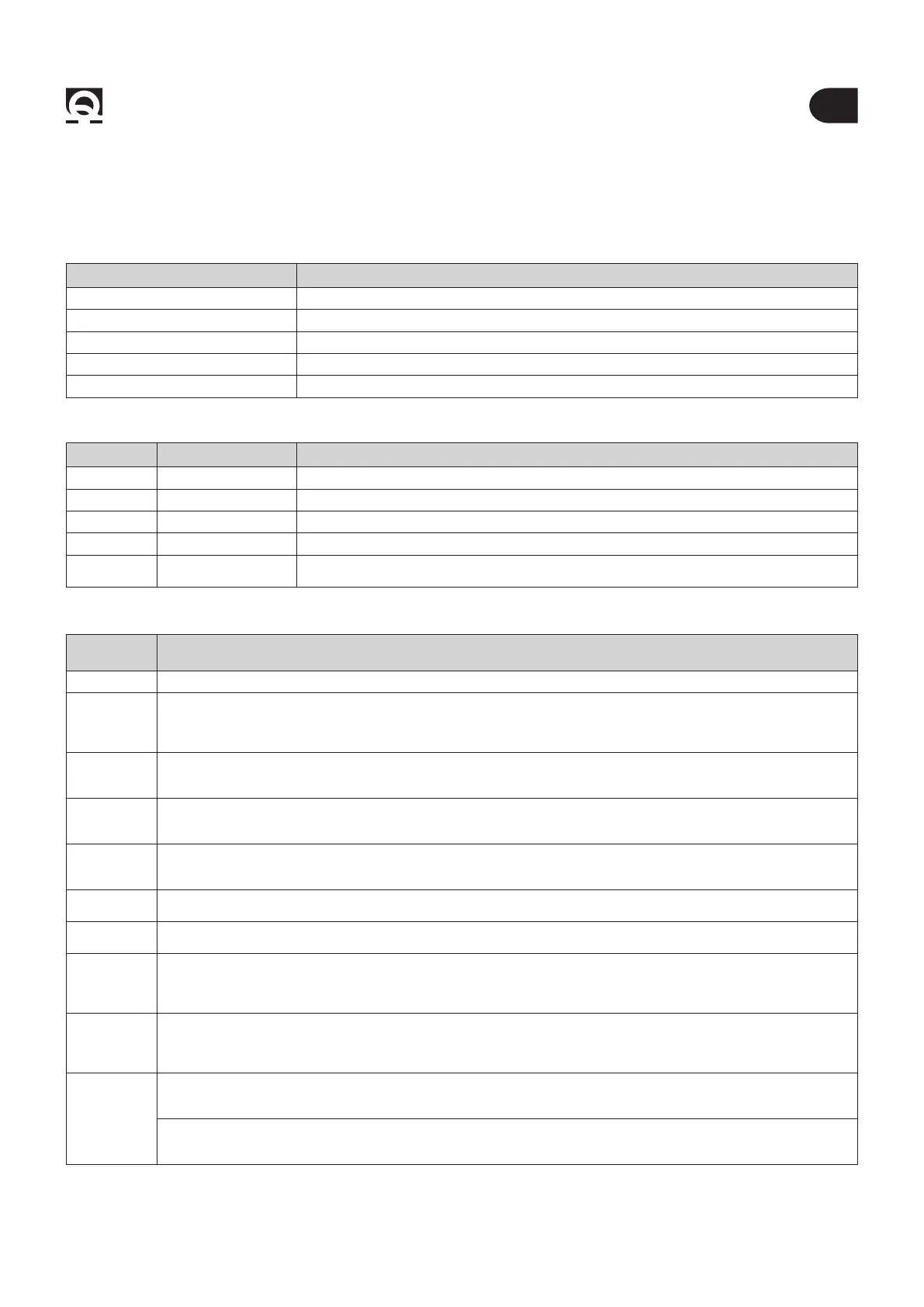

7.0 - Notification signs

At the end of the cyclical flashing sequence, the “ERROR” LED remains off for a short period.

LED ERROR (RED)

NUMBER OF

FLASHING

DESCRIPTION

NOTHING No anomaly present.

1

High absorption of the actuator during ascent (retractable thruster closing)

Signalling occurs after the system has attempted three ascents in the presence of mechanical friction exceeding the set threshold.

The problem can be caused by a foreign body that entered the mechanism, by the vessel navigating at sustained speed, or by me-

chanical problems of the retractable and relative hatch.

2

Open fuse.

A current absorption exceeding 10A has occurred. The problem can arise from a short circuit or an overload on the actuator power

line. Verify the wiring of the power lines from the board to the actuator or the absorption of the actuator itself.

3

Anomalous limit switch’s condition.

The problem is signalled when the board detects an anomaly on the limit switches (both activated). Verify the wiring of the power

lines from the board to the limit switches and their functionality.

4

Actuator command line interruption.

The problem is signalled when the board detects an interruption in the command power lines of the actuator. Verify the wiring of

the power lines from the board to the actuator.

5

Timeout of actuator’s movement intervention.

The problem is signalled when the movement command given to the actuator is not executed within 15 seconds.

6

Mistaken dip-switch setting.

The problem is signalled when the dip-switch positions have not been set correctly.

7

High absorption of the actuator during descent (retractable thruster opening).

Signalling occurs after the system has attempted three descents in the presence of mechanical friction exceeding the set thresh-

old. The problem can be caused by a foreign body that entered the mechanism, by the vessel navigating at sustained speed, or by

mechanical problems of the retractable thruster and relative hatch.

8

High absorption on motor reversing contactor unit control’s output.

The problem is signalled when the board detects a short circuit or an overload on the electric control line of the propeller.

Verify the wiring on the power lines from the board to the propeller and the absorption of the motor reversing contactor unit in-

stalled on the propeller.

9

Activation of the thermal protection on the motor

The problem is notified in case the thermal protection on the motor is tripped.

Wait for the thruster to cool off.

Interrupted connection on the motor reversing contactor unit control’s output.

The problem is signalled when the board detects an interruption on the electric control line of the propeller.

Verify the wiring of the power lines from the board to the motor reversing contactor unit installed on the propeller.

Legend of error notications concerning the RTC R1 board (see the board on page 38)

Loading...

Loading...