26

EN

RETRACTABLE THRUSTER BTR185 - IT EN - REV008B

Conversion from decimal to fractional inches

3 mm = 1/8” in 26 mm = 1” 1/32 in

5 mm = 3/16” in 35 mm = 1” 3/8 in

8 mm = 5/16” in 45 mm = 1” 49/64 in

8,5 mm = 21/64” in 80 mm = 3” 5/32 in

10 mm = 25/64” in 95 mm = 3” 3/4 in

15 mm = 19/32” in 100 mm = 3” 15/16 in

20 mm = 25/32” in 280 mm = 11” 1/32 in

350 mm = 13” 25/32 in

INSTALLATION

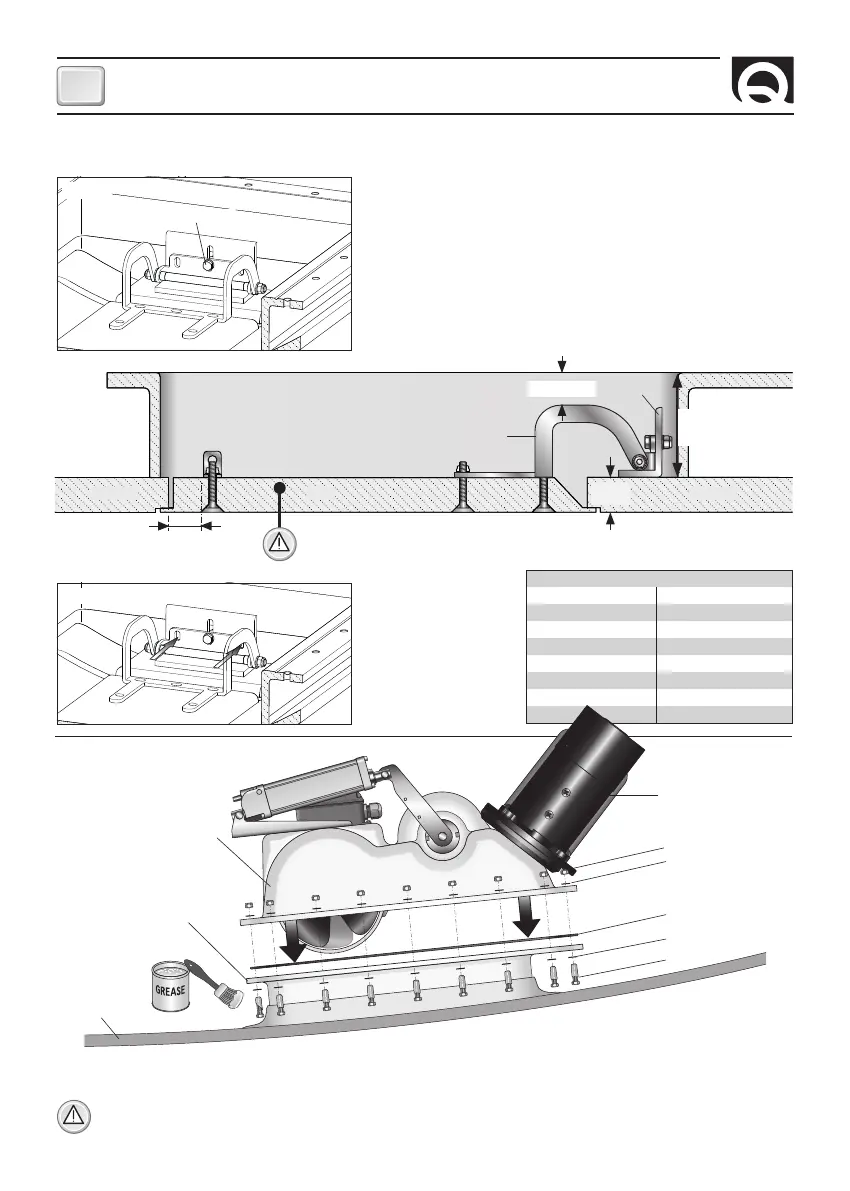

Fig. 14

• Assemble the thruster to the counter flange, which is now integral with the hull, by means of the bolts and screws provided

(spread some marine grease on the bolts’ thread), by verifying the correct positioning of the gasket on the counter flange (fig.14).

WARNING: about one week after installation, you should check that all screws are properly tightened in order to compen

-

sate for any potential O-ring settling.

Thruster’s installation

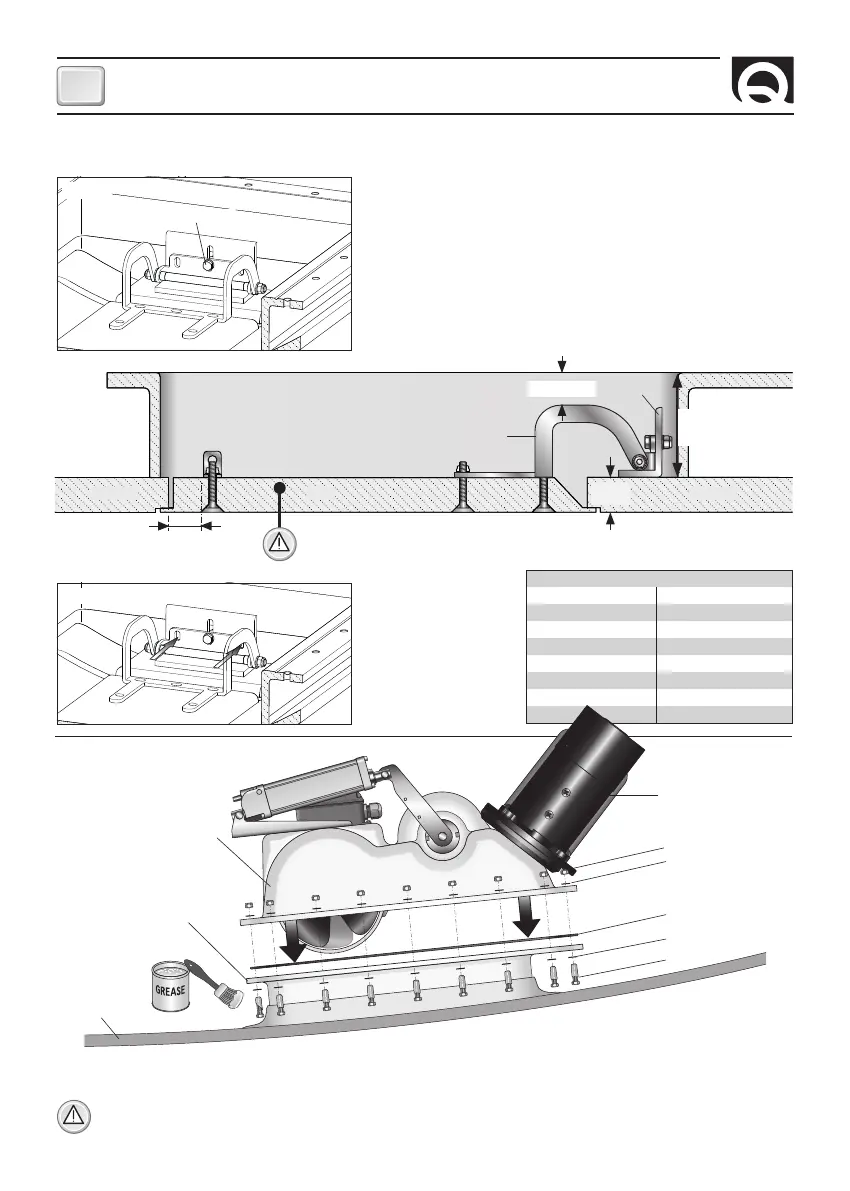

Fig. 12

15 mm

LID

Max

35 mm

COUNTER FLANGE

HINGE

LID BRACKET

HULLHULL

• Temporarily fasten the hinge bracket in its housing.

• Screw the hinge onto the lid bracket with the central screw only (fig. 11).

• Position the hinge and hinge bracket correctly in the correct positions.

Mark all the fastening points (fig. 12), remove the hinge and hinge bracket

and drill using the Ø 8.5 mm bit.

Fasten the hinge and hinge bracket in the positions marked with stainless

steel hardware suitable for the application.

Adjust the central screw of the hinge (fig. 11) and position it correctly so

that the hatch opens without any hindrance.

CENTRAL SCREW

Fig. 11

Closing lid’s preparation and installation

• Drill the angle bar and

fasten securely with

the other two M8

screws (fig. 13).

N. 2 SCREWS M8

Fig. 13

O-RING

BOLT

WASHER

MOTOR

WASHER

NUT

COUNTER FLANGE

HULL

THRUSTER

Min.

80 mm

WARNING: in order to allow a stable fixing of hinge and bracket, the lid must present

neither empty areas nor non-structural fillings inside (fig. 12).

Min. 5 mm

Loading...

Loading...