>-

Sedon 7- Service

Adjustments

*Differential Pilot Valve

*Vaauun Switch

*Water Temperature Regulating Valve

*Coupling Alignment

*Correcting Angular Mkaligoment

*Water-Cooled Heat Exchanger

Differential Pilot Valve

Open a manual vent valve on the inlet to the vacuum

pump and start the unit. By manual regulation slowly

close the valve, allowing the system pressure to reach

the desired vacuum level. Adjust the screw on the

bottom of the diEerential pilot valve so that a slight

vibration can be detected at the point of desired system

modulation. When this vibration is felt, air is

beginning to pass through the pilot valve to the air

cylinder on the inlet valve, causing the valve to

modulate toward its closed position, thereby, reducing

the volume of air being drawn in to the pump.

To raise pressure turn the adjusting screw in

(clockwise). To lower pressure, turn the screw out

(counter ckdcvvise). Maximum vacuum under

modulation is 29.6” HgV. for the QSVI vacuum pumps

(29.9” HgV without modulation).

Vactmm Switch

The pressure switch determines at what pressure the

vacuum pump will load and unload. Standard factory

settings are listed in the QSVI Specit%xtions. If a

lower setting is desird adjust the differential pilot

valve first and set the pressure switch cut-out point to

no less than 2“ HgV differential. That adjustment is

made by turning the wheel clockwise to increase the

eut-inknt-out pressure and counter clockwise to lower

Cut-irdcut-out pressure. The vacuum switch should

unload the vacuum pump by the time it reaches the 20°/0

load point.

Water Temperature Remdatin~ Valve (water-cooled

units)

The water temperature regulating valve senses fluid

temperature and opens or closes, regulating water flow

fkom the unit. It is factory set to maintain 160° F fluid

,.”..

injeetion temperature as shown by the fluid inlet

temperature gauge. Due to cMYerentincoming water

temperature andlor pressures at the customers location,

valve adjustment should be checked during start-up to

maintain 160”F fluid inlet temperature. To increase

fluid temperature, decrease water flow by turning the

adjusting screw clockwise. To decrease fluid

temperature, increase water flow by turning the

adjustment screw counter clockwise.

Cou~lin~ Ali@ment

Compressor and motor bearing life can be maximized

only when both components are in alignment to each

other. Prior to new unit start-up or after any vacuum

pump or motor change the drive alignment must be

checked. If the vacuum pump is ever accidentally

knocked out of place or relocated, the drive alignment

must be checked, Note! Some QSVI models are

permanently aligned and the above statement wiIl

not apply to those models. Check your machine for

alignment type.

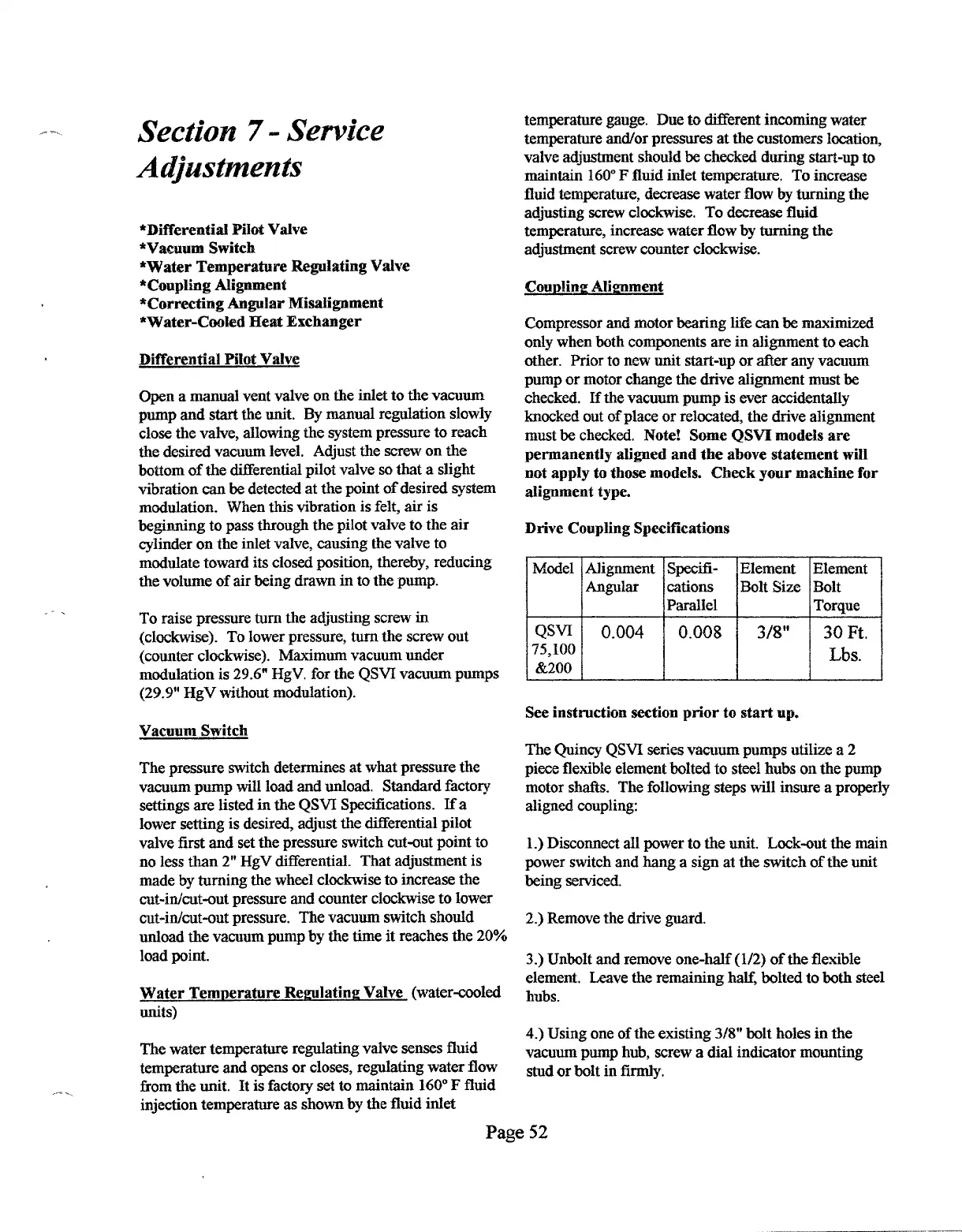

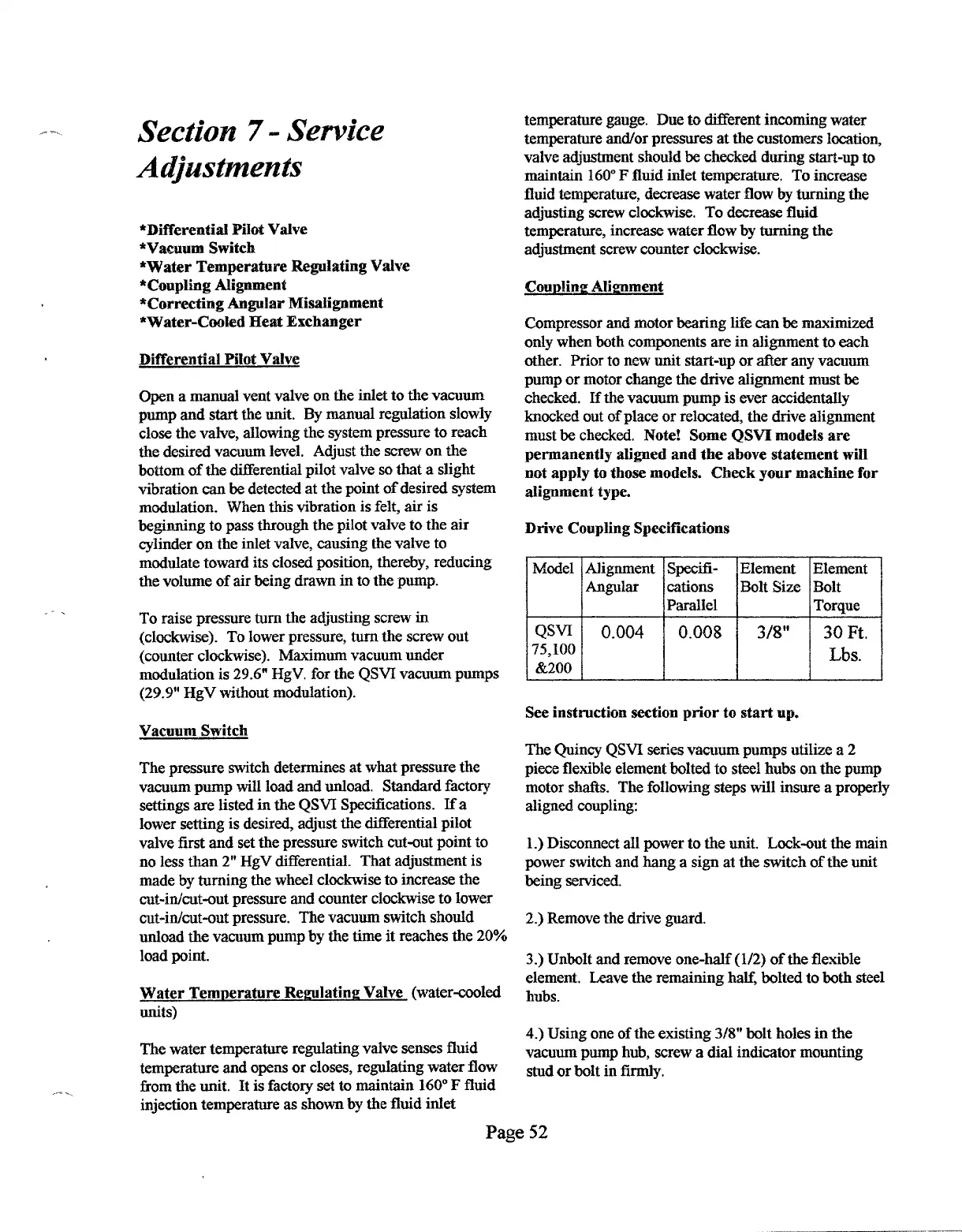

Drive Coupling Specifications

IModel IAlignment ]Specifi-

P

Element

Bolt Size

3/8”

3

Element

Bolt

Torque

30 Ft.

Lbs.

See instruction section prior to start up.

The Quiney QSVI series vacuum pumps utilize a 2

piece flexibIe element bolted to steel hubs on the pump

motor shatis. The following steps will insure a properly

aligned coupling:

1.) DiscoMeet aIl power to the tit. Leek-out the main

power switch and hang a sign at the switch of the unit

being serviced.

2.) Remove the drive guard.

3.) Unbolt and remove one-half (1/2) of the flexible

element, Leave the remaining half, bolted to both steel

hubs.

4,) Using one of the existing 3/8” bolt holes in the

vacuum pump hub, screw a dial indicator mounting

stud or bolt in firmly.

Page 52

Loading...

Loading...