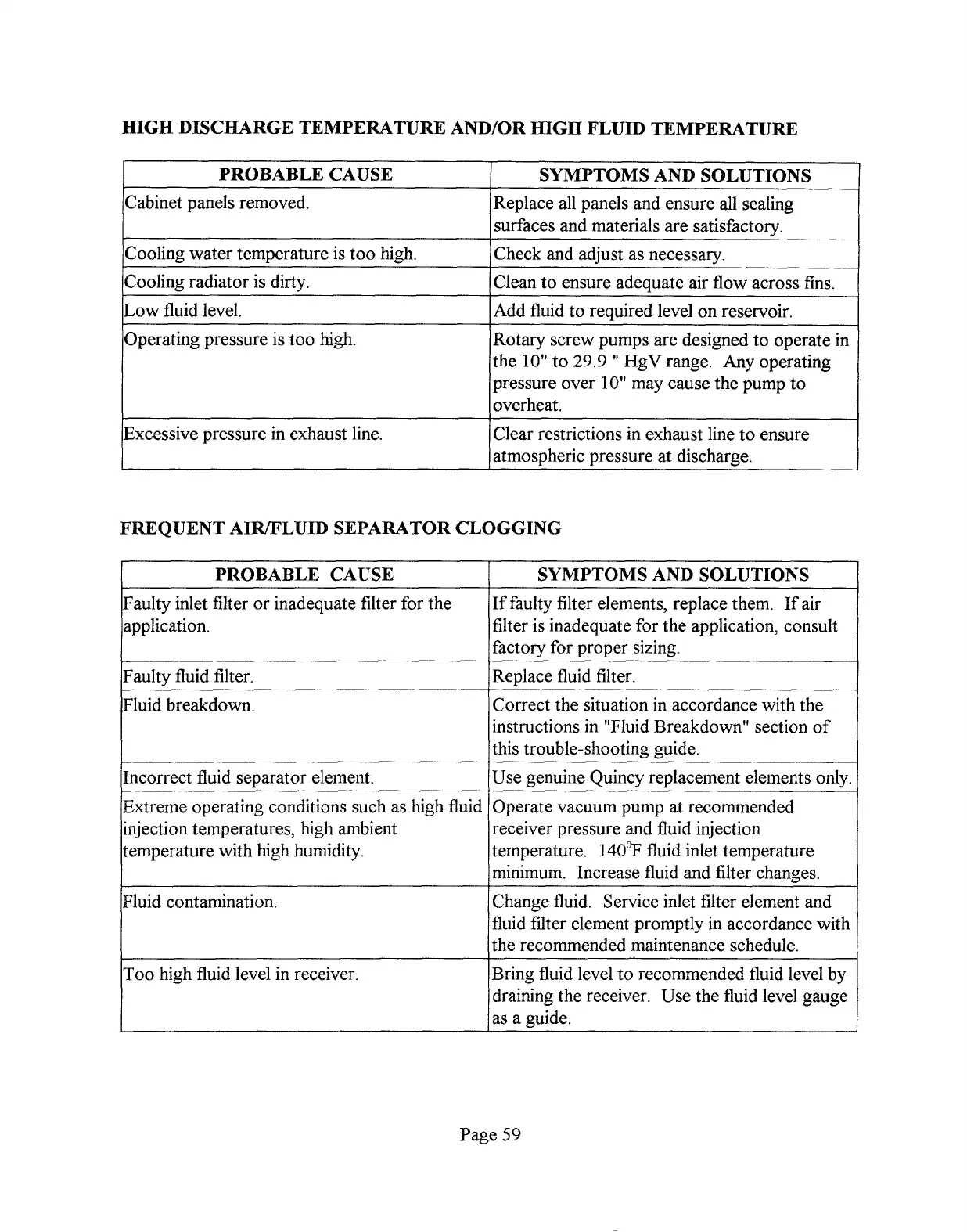

HIGH DISCHARGE TEMPERATURE AND/OR HIGH FLUID TEMPERATURE

PROBABLE CAUSE

SYMPTOMS AND SOLUTIONS

;abinet panels removed. Replace all panels and ensure all sealing

surilaces and materials are satisfacto~.

;ooling water temperature is too high. Check and adjust as necessary.

;ooling radiator is dirty. Clean to ensure adequate air flow across fins.

.OWfluid level.

Add fluid to required level on reservoir.

)perating pressure is too high. Rotary screw pumps are designed to operate in

the 10” to 29.9 “ HgV range. Any operating

pressure over 10” may cause the pump to

overheat.

Lxcessive pressure in exhaust line.

Clear restrictions in exhaust line to ensure

atmospheric pressure at discharge.

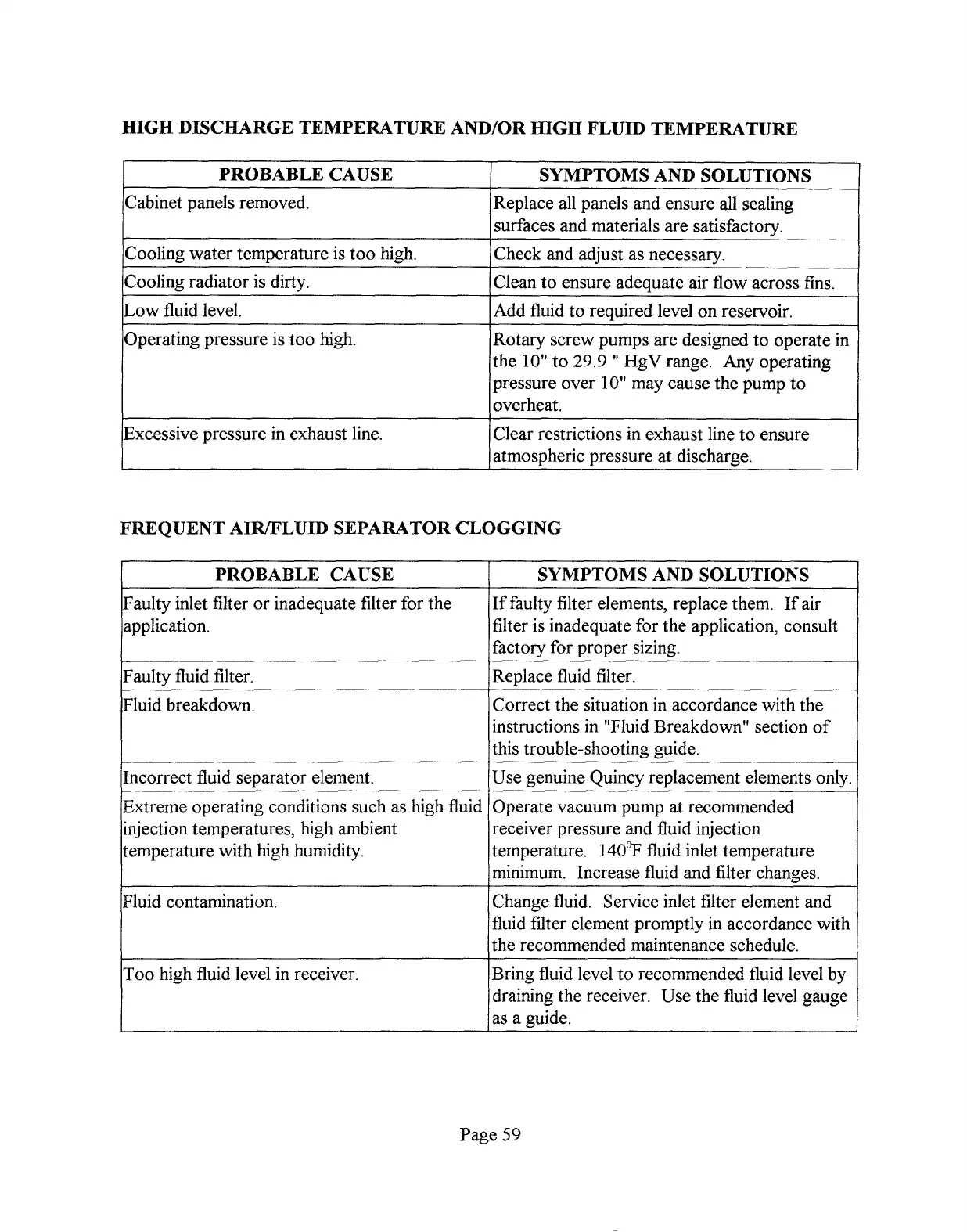

FREQUENT AHUFLUID SEPARATOR CLOGGING

I

PROBABLE CAUSE

I

SYMPTOMS AND SOLUTIONS

Faulty inlet filter or inadequate filter for the

If faulty filter elements, replace them. If air

application.

filter is inadequate for the application, consult

factory for proper sizing.

/Faulty fluid filter.

/Replace fluid filter.

Fluid breakdown.

Correct the situation in accordance with the

instructions in “Fluid Breakdown” section of

this trouble-shooting guide.

Incorrect fluid separator element.

Extreme operating conditions such as high fluid

injection temperatures, high ambient

temperature with high humidity.

Use genuine Quincy replacement elements only.

Operate vacuum pump at recommended

receiver pressure and fluid injection

temperature. 140!F fluid inlet temperature

minimum. Increase fluid and filter changes.

Fluid contamination.

I

Change fluid. Service inlet filter element and

fluid filter element promptly in accordance with

the recommended maintenance schedule.

Too high fluid level in receiver.

Bring fluid level to recommended fluid level by

draining the receiver. Use the fluid level gauge

as a guide.

Page 59

. ..- ..—

. ... -—.-. .—

. .. .. ..-—----

-—-

.. ...

Loading...

Loading...