3 OM-20000 SERIES LOW PROFILE EQUIPMENT TABLES

NOTE: Numbers on pressure control are pounds of pressure, not degrees F.

NOTE: Do not adjust the differential screw.

DRAWER REMOVAL

1. Fully extend the drawer that is to be removed.

2. Remove product pans from drawer.

3. Lift up the drawer stop tabs on each side of drawer track.

4. Pull drawer out while lifting the tabs.

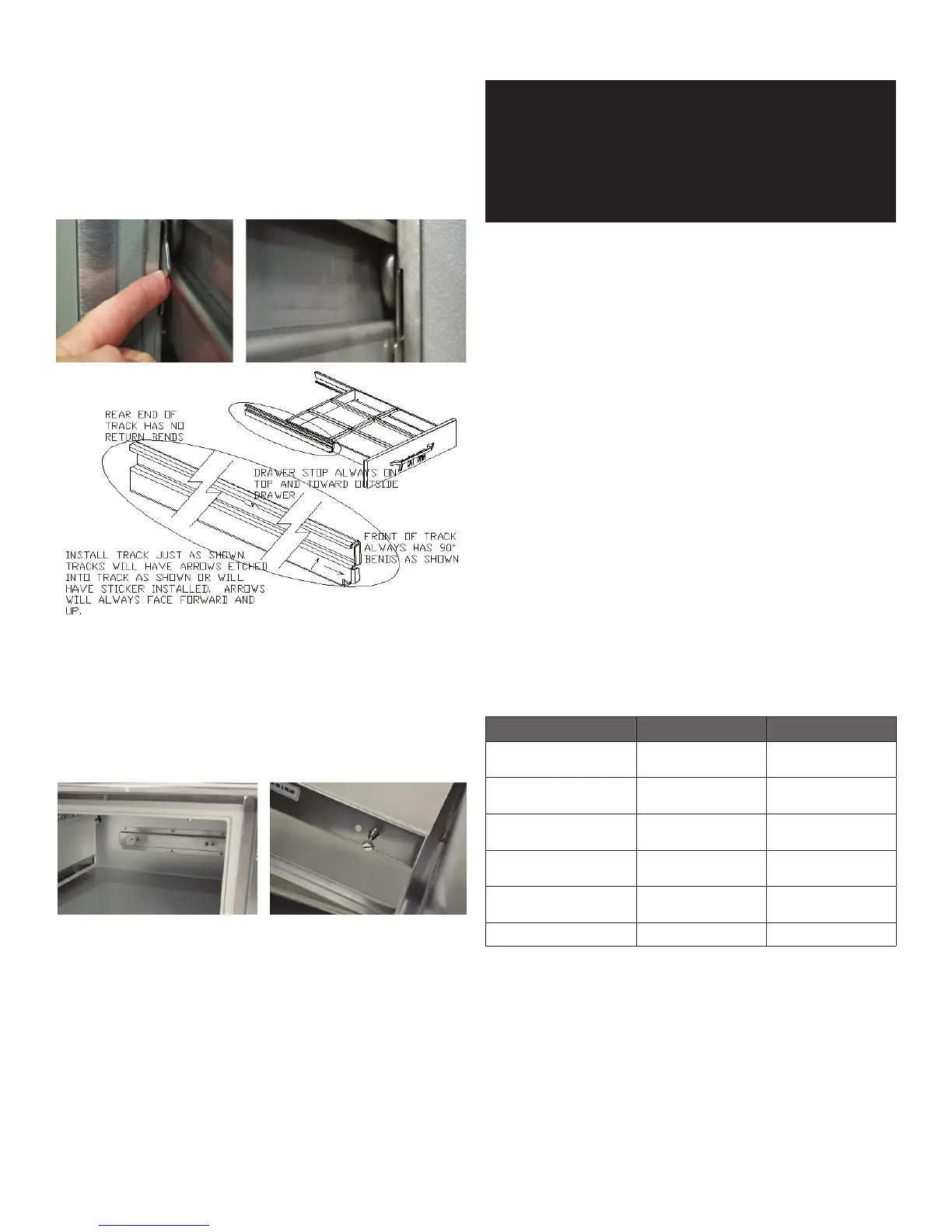

DRAWER INSTALLATION

To remove and re-install individual drawers and drawer tracks, please refer to the

figure above for proper installation instructions.

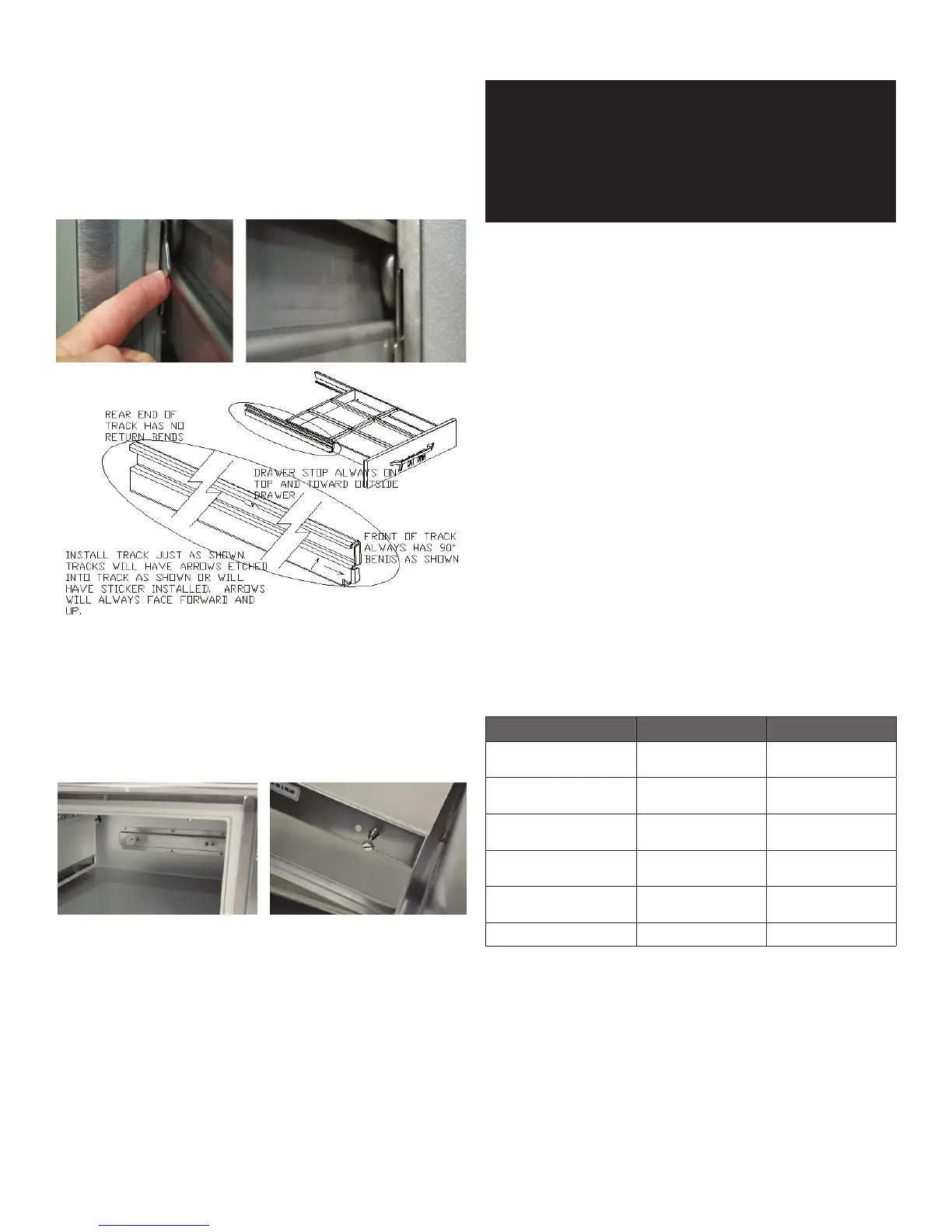

DRAWER CARTRIDGE SYSTEM REMOVAL

Drawer cartridge system has a single plate in rear to hold in place. To remove the

entire drawer system, unscrew the thumb screws on rear wall to detach system

from the plate. See figures below.

MAINTENANCE

WARNING: DO NOT USE SHARP UTENSILS AND/OR OBJECTS.

WARNING: DO NOT USE STEEL PADS, WIRE BRUSHES, SCRAPERS, OR CHLORIDE

CLEANERS TO CLEAN YOUR STAINLESS STEEL.

CAUTION: DO NOT USE ABRASIVE CLEANING SOLVENTS, AND NEVER USE

HYDROCHLORIC ACID (MURIATIC ACID) ON STAINLESS STEEL.

WARNING: DO NOT PRESSURE WASH EQUIPMENT AS DAMAGE TO ELECTRICAL

COMPONENTS MAY RESULT.

Unified Brands strongly suggests a preventive maintenance program which would

include the following monthly procedures:

If a failure of the equipment is a direct result of any of the Preventative Maintenance

guidelines being neglected, the repairs and parts replacements will not be covered

under warranty.

It is recommended that the customer contact the local Authorized Service Agent to

provide a quote to perform periodic Preventative Maintenance.

MONTHLY PM PROCEDURES

1. Cleaning of all condenser coils. Condenser coils are a critical component in

the life of the compressor and must remain clean to assure proper air flow and

heat transfer. Failure to maintain this heat transfer will affect unit performance

and eventually destroy the compressor. Clean the condenser coils with coil

cleaner and/or a vacuum, cleaner and brush. NOTE: Brush coil in direction of

fins, normally vertically as to not damage or restrict air from passing through

condenser.

2. Clean fan blade on the condensing unit.

3. Clean and disinfect drains with a solution of warm water and mild detergent

4. Clean and disinfect drain lines and evaporator pan with a solution of warm

water and mild detergent

5. Clean all gaskets on a weekly if not daily basis with a solution of warm water

and a mild detergent to extend gasket life.

6. Remove debris from drawer slides.

RECOMMENDED CLEANERS FOR YOUR STAINLESS STEEL INCLUDE THE

FOLLOWING:

JOB CLEANING AGENT COMMENTS

Routine cleaning

Soap, ammonia,

detergent Medallion

Apply with a sponge or

cloth

Fingerprints and smears

Arcal 20, Lac-O-Nu,

Ecoshine

Provides a barrier film

Stubborn stains and

discoloration

Cameo, Talc, Zud,

First Impression

Rub in the direction of

the polish lines

Greasy and fatty acids, blood,

burnt-on foods

Easy-Off, Degrease It,

Oven Aid

Excellent removal on all

finishes

Grease and Oil

Any good commercial

detergent

Apply with a sponge or

cloth

Restoration/Preservation Benefit, Super Sheen Good idea monthly

Reference: Nickel Development Institute, Diversey Lever, Savin, Ecolab, NAFEM

Proper maintenance of equipment is the ultimate necessity in preventing costly

repairs. By evaluating each unit on a regular schedule, you can often catch

and repair minor problems before they completely disable the unit and become

burdensome on your entire operation.

For more information on preventive maintenance, consult your local service

company or CFESA member. Most repair companies offer this service at very

reasonable rates to allow you the time you need to run your business along with

the peace of mind that all your equipment will last throughout its expected life.

These services often offer guarantees as well as the flexibility in scheduling or

maintenance for your convenience. For a complete listing of current Unified Brands

ASA please visit www.unifiedbrands.net.

Loading...

Loading...