8

A

WARNING: Blockage of suction ttings can cause

serious or fatal injury due to drowning. To reduce the

risk of injury, do not permit children to use this product.

5. INSTALLATION

A

WARNING: Chemical fumes and/or spills can cause

serious corrosion to the lter and pump structural

components. Structurally-weakened components can

cause lter, pump or valve attachments to separate and

could cause serious bodily injury or property damage.

A

WARNING: The system's centrifugal pump operates

with electrical voltage, and can generate both vacuum

and pressure in the water system. When properly wired

and plumbed, this pump will operate in a safe manner.

A

WARNING: Never work on the pump while it is

running or power is still connected. High voltage can

cause serious or fatal injury. A suitable ground fault

interrupter (GFCI) should always be installed at the

power supply source of this unit. Article 681-31 of the

NEC requires that a GFCI be used if this pump is used

with a storage pool. Be sure to ground the motor before

connecting to electrical AC power source. Failure to

ground the motor can cause serious or fatal electrical

shock hazard. DO NOT ground to a gas supply pipe line.

A

DANGER: High-pressure release

from the sand lter can cause severe

injury or major property damage due

to parts ying open or apart. Release

all pressure in the sand lter before

doing any work on it. For example, avoid

adjusting the lter clamp under pressure

as that can cause it to separate resulting

in serious injury or property damage.

Pump

1. Only qualified, licensed personnel should install

pump and wiring.

2. Electrical Contractors Please Note: All 115VAC 60Hz

pumps must be wired to the main power supply

through an approved and correctly-rated contactor.

3. Allow for gate valve in suction piping.

Pump suction and discharge connections have molded

in thread stops,do not try to screw pipe in beyond these

stops.

Pump Mount

• Must be on a solid, level, rigid and vibration-free

surface.

• Ensure pump suction inlet height to be as close to

pool water level as possible. Ensure the use of a

short, direct suction pipe, to reduce friction losses.

• Avoid installing the pump above the water level.

Suction lifts of more than 6" (152 mm) will cause

very long priming times, and potentially damage the

pump.

• Allow for gate valves in the suction and discharge

piping. Ensure adequate floor drainage to prevent

flooding.

• Protect from excess moisture.

• Ensure adequate access for servicing the pump,

filter, and piping.

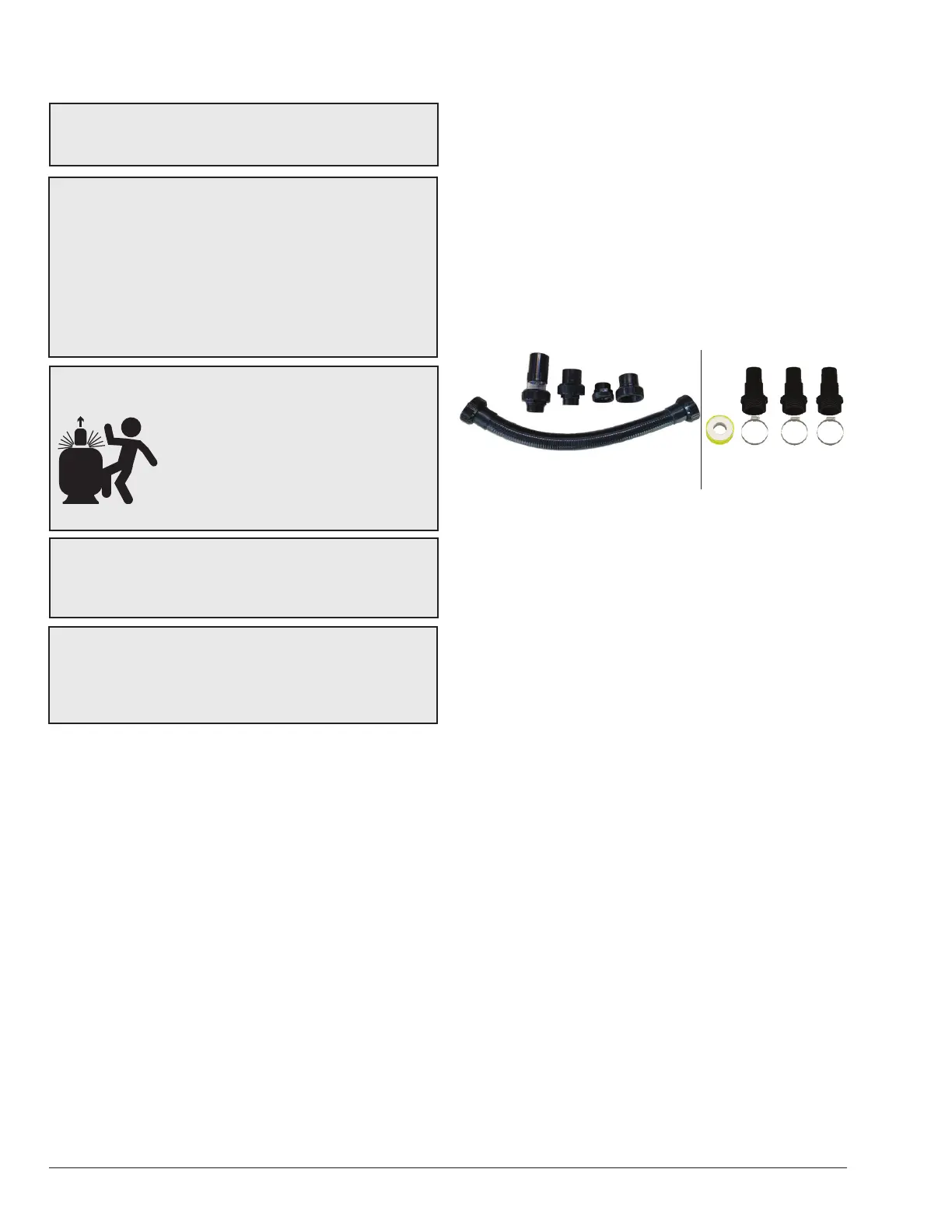

Packaging

A hose barb kit and union kit are included and needed to

make the connections.

UNION KIT HOSE BARB KIT

Figure 1. Connection Kits

Pump Assembly Steps

1. The system should be installed as close as possible

to the swimming pool and preferably at a level of 20"

(0.5 m) below the level of the water in the swimming

pool. It should be preferably in a dry, well-ventilated

area away from direct sunlight and on a hard, level

surface. Make sure there is drainage available at

the place where the filter is to be installed. Give

consideration to:

a. Drainage far away from pump.

b. Ventilation of the pump motor.

c. Access for future servicing and winterizing.

2. Bolt the pump onto the platform.

3. Connect the suction and discharge pipes to the outlet

and inlet of the swimming pool.

4. The pump motor must be wired in accordance with

the wiring diagram supplied with the motor using

the right voltage. Wiring the motor with the incorrect

voltage will cause damage to the motor. Such

damage will not be covered under warranty.

5. Install, ground and bond wire according to local or

National Electrical Code requirements.

6. Permanently ground the motor. Locate the ground

terminal located on the rear side of the motor and

use the wire gauge and type required by code to

connect the motor ground terminal to the electrical

service ground. On cord-connected circuits, check

for proper grounding.

Loading...

Loading...