❑ mmm THE OVENBURHEROR9F9CES

oven Bu8’ner

1. Remove oven door, storage drawer or broiler

drawer and oven bottom..The lower burner

orifice spud is located behind the storage drawer,

broiler drawer or kick panel. (On some models, a

metal shield must be removed to access the

orifice.)

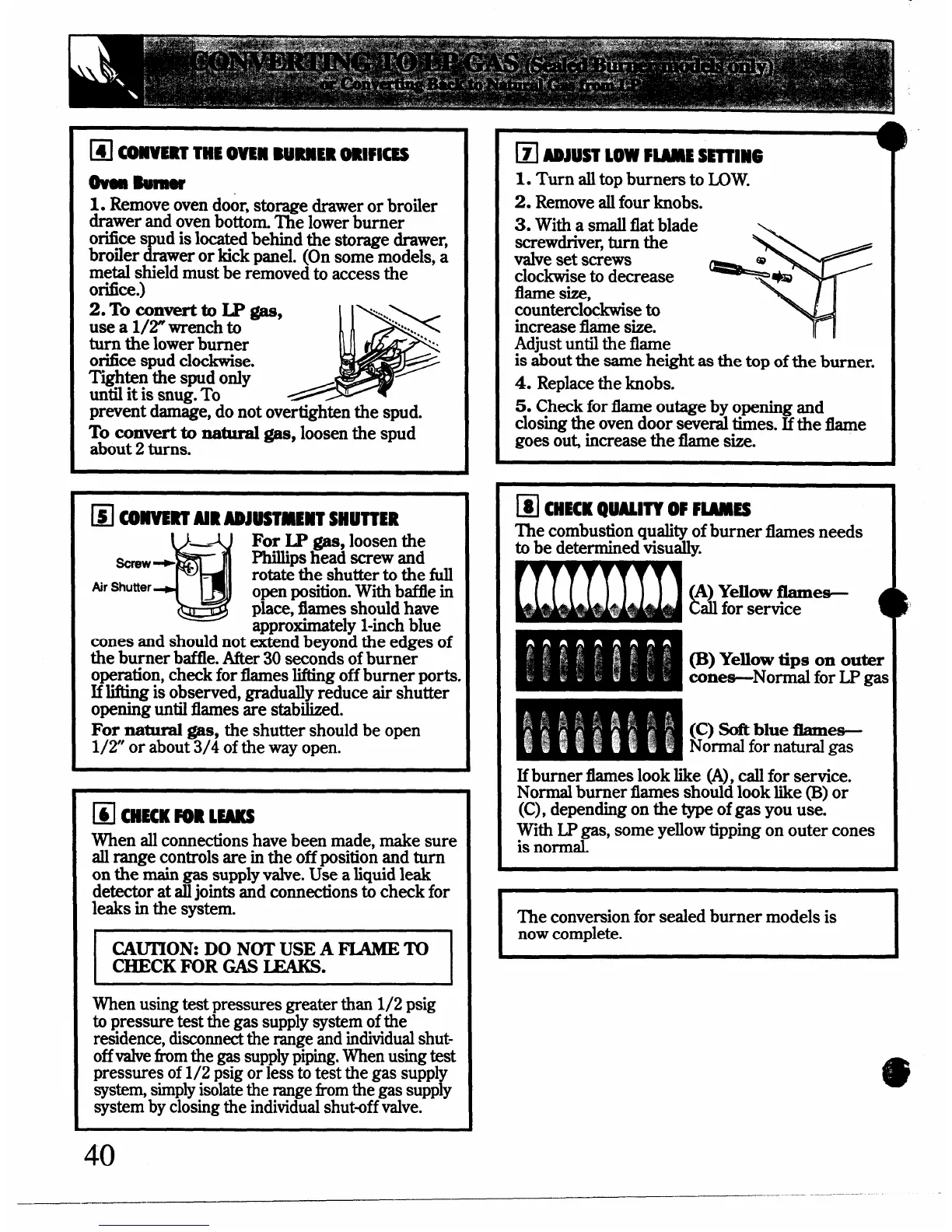

2. To convert ti LP gas,

use a 1/2” wrench to

turn the

lower burner

orifice spud cloclmise.

Tighten the spud only

until it is snug. To

prevent damage, do not overtighten the spud.

To

convertto naturalgas, loosen the spud

about 2 turns.

E

CMVERTAIRADJUSTMEHT SHUTTER

For LP gas, loosen the

screw

~PS

head screw and

rotate the shutter to the full

Air Shutter

open position.W~thbaffle in

place, flames should have

approximately l-inch blue

cones and should not extend beyond the edges of

the burner bathe. After 30 seconds of burner

operation, check for flames lifting offburner ports.

Iflifting is observed, gradually reduce air shutter

opening until flames are stabilized.

For natural gas, the shutter should be open

1/2” or about 3/4 ofthe way open.

❑ CHECKFOR LEAKS

When all comections have been made, make sure

all range controls are in the offposition and turn

on the main gas supply valve. Use a liquid leak

detector at alljoints and connections to check for

leaks in the system.

CAUTION: DO NOT USE A I?MME ‘IT)

CHECK FOR GAS IJMKS.

When using test pressures greater than 1/2 psig

to pressure test the gas supply system ofthe

residence, discomect the range and individualshut-

offvalvefromthe gas supplypiping.When using test

pressures of 1/2 psig or less to test the gas supply

system, simplyisolatethe range fromthe gas supply

system by closing the individualshut~ff valve.

2. Remove all four knobs.

3. With a small flat blade

screwdriver, turn the

valve set screws

clockwise to decrease

%

<*

flame size,

counterclockwise to

increase flame size.

Adjust until the flame

is about the same height as the top of the burner.

4. Replace the knobs.

5. Check for flame outage by opening and

closing the oven door several times. If the flame

goes out increase the flame size.

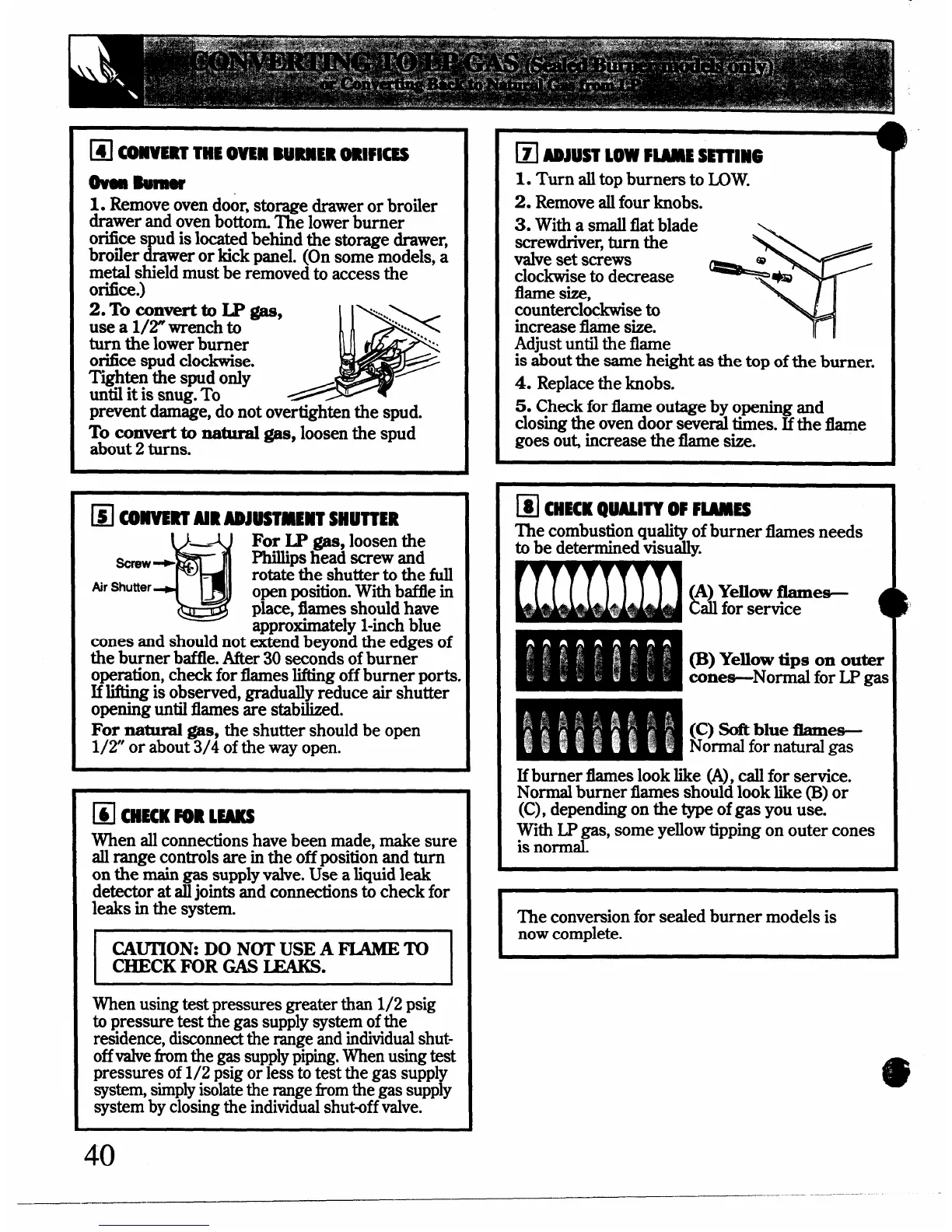

❑ CHECKQUALITY OF FLAMES

The combustion qwdity of burner flames needs

to be determined visually

A Yellow flatnes-

&)

all for service

1

(B) Yellow tips on outer

cones-Normal for LP gas

(C) Soft blue fiames-

Normal

for natural gas

Ifbumer flames look like (A),call for service.

Normal burner flames should look like (B)or

(C), depending on the type of gas you use.

~n~m~das, some yellow tipping on outer cones

.

)“

k’

The conversion for sealed burner models is

now complete.

I

40

—...——-

..—

Loading...

Loading...