I

b&

owaBu9’ner

1.

Remove oven door, storage drawer or broiler

drawer and oven bottom. The lower burner

orifice spud is located behind the storage drawer,

broiler drawer or kick panel. (On some models, a

metal shield must be removed to access the

orifice.)

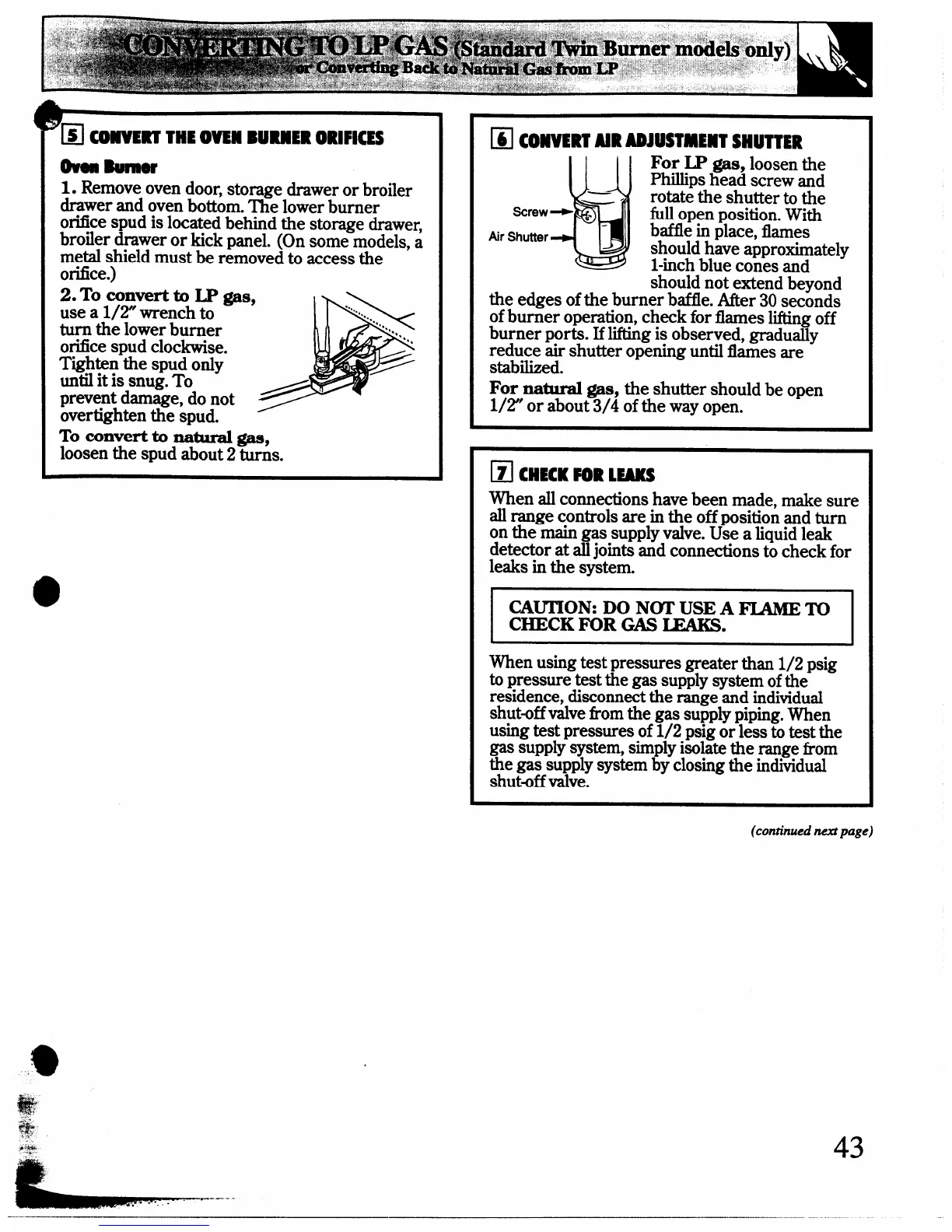

2. To

convertto LP gas,

use a 1/2” wrench to

turn the lower burner

orifice spud clockwise.

T~hten the spud only

until it is snug. To

prevent damage, do not

overtighten the spud. ‘

To

convertto naturalgas,

loosen the spud about 2 turns.

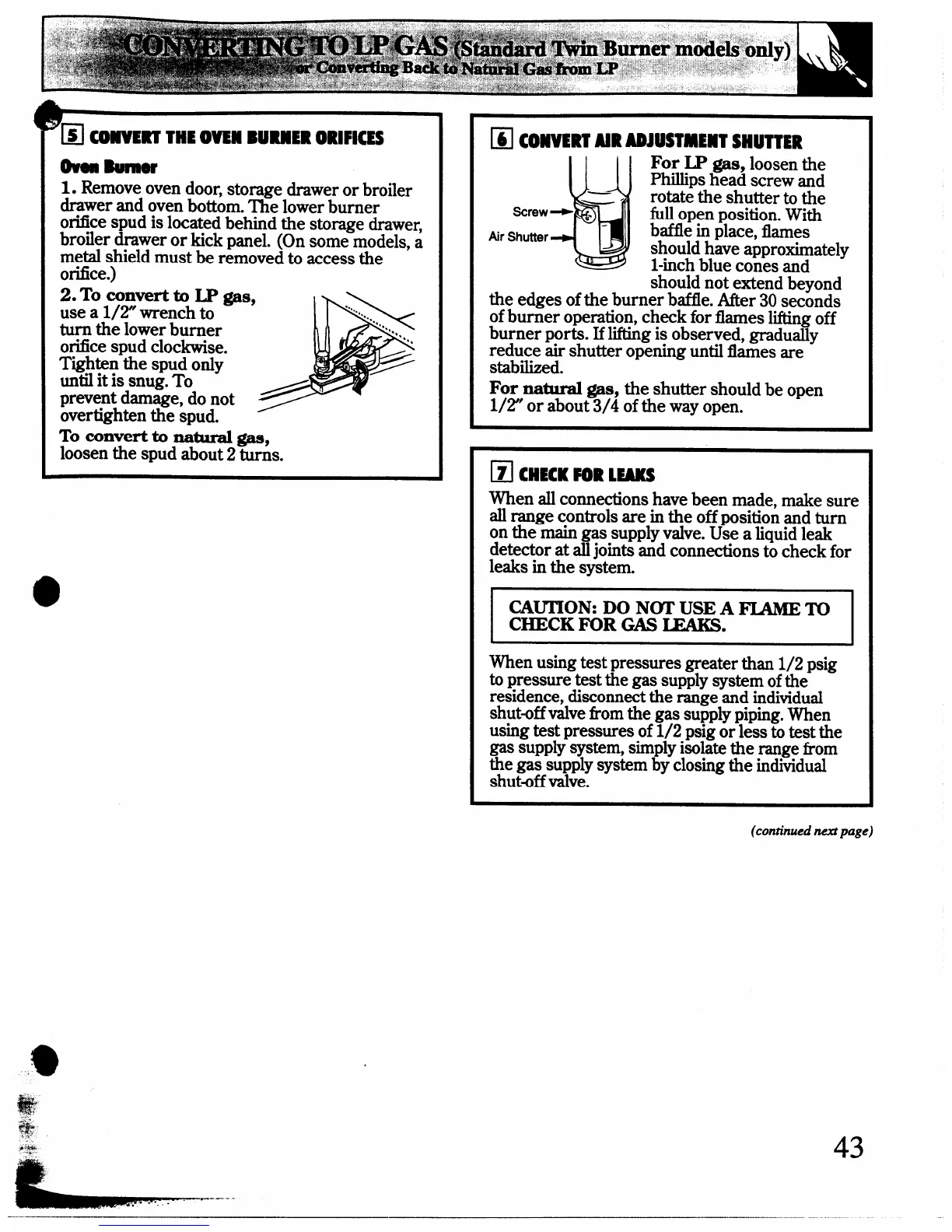

❑ CONVERT NR~JusTmEMl SHUTTER

For LP gas, loosen the

Phillips head screw and

rotate the shutter to the

Screw

fill

open position. With

Air Shutter

baffle in place, flames

should have approximately

l-iich blue cones and

should not extend beyond

the edges of the burner baffle. After 30 seconds

of burner operation, check for flames lifting off

burner ports. Iflifti.ngis observed, gradually

reduce air shutter opening until flames are

stabilized.

For natural gas, the shutter should be open

1/2” or about 3/4 ofthe way open.

❑ CHECKFOR LEAKS

When all connections have been made, make sure

all range controls are in the off position and turn

on the main gas supply valve. Use a liquid leak

detector at alljoints and connections to check for

leaks in the system.

CAUTION: DO N(YI’USE A FIAME TO

CHECK FOR GAS IEAKS.

When using test pressures greater than 1/2 psig

to pressure test the gas supply system ofthe

residence, disconnect the range and individual

shutdt valvefrom the gas supply piping.When

using test pressures of 1/2 psig or less to test the

gas supply system, simply isolate the range from

the gas supplysystem by closing the individual

shut-offvalve.

(continued next page)

e

$.,

Loading...

Loading...