13

9. Adjustments & Maintenance

Checking the Belt Tension

Before attempting to use the machine, check that the correct speed is

selected in relation to the size and type of drill bit and type of material

being machined. It is important to apply the correct level of tension. Over-

tensioning the belt will apply excessive load to the motor and spindle

bearings and may cause damage to the machine. Insufficient tensioning of

the belt will cause the machine to be noisy as there will be excess movement

of the belt as it runs between the pulleys and the spindle may stall when

machining as pressure is applied to the work piece. Periodically check the

belt tension to maintain optimum performance of the machine.

Before attempting any maintenance or adjustment ALWAYS

ensure that the machine is disconnected from the power supply.

Changing the Speed Setting

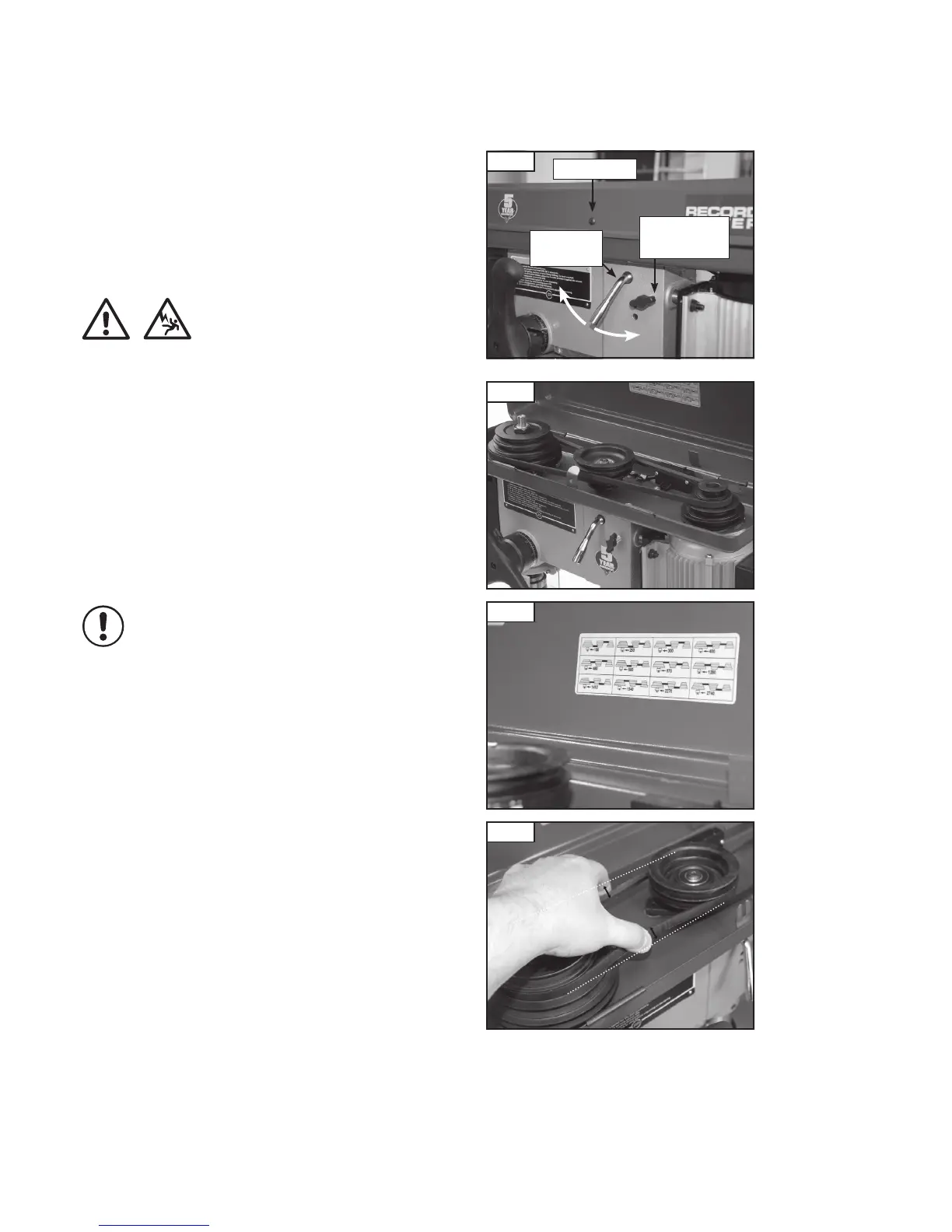

1. Remove the locking screw from the belt guard, (Fig 9.1).

2. Unscrew the belt tension locking handles (Fig 9.1) located at each side

of the head unit.

3. Use the belt tension cam handle to release tension on the drive belt by

turning it anti-clockwise.

4. Re-position the drive belts (Fig. 9.2) to correspond with the appropriate

speed as shown on the speed chart inside the belt guard (Fig. 9.3).

5. Reapply tension to the drive belt by turning the belt tension cam handle

clockwise. Whilst holding the belt tension cam handle to maintain tension,

tighten the tension locking handles at each side of the head unit.

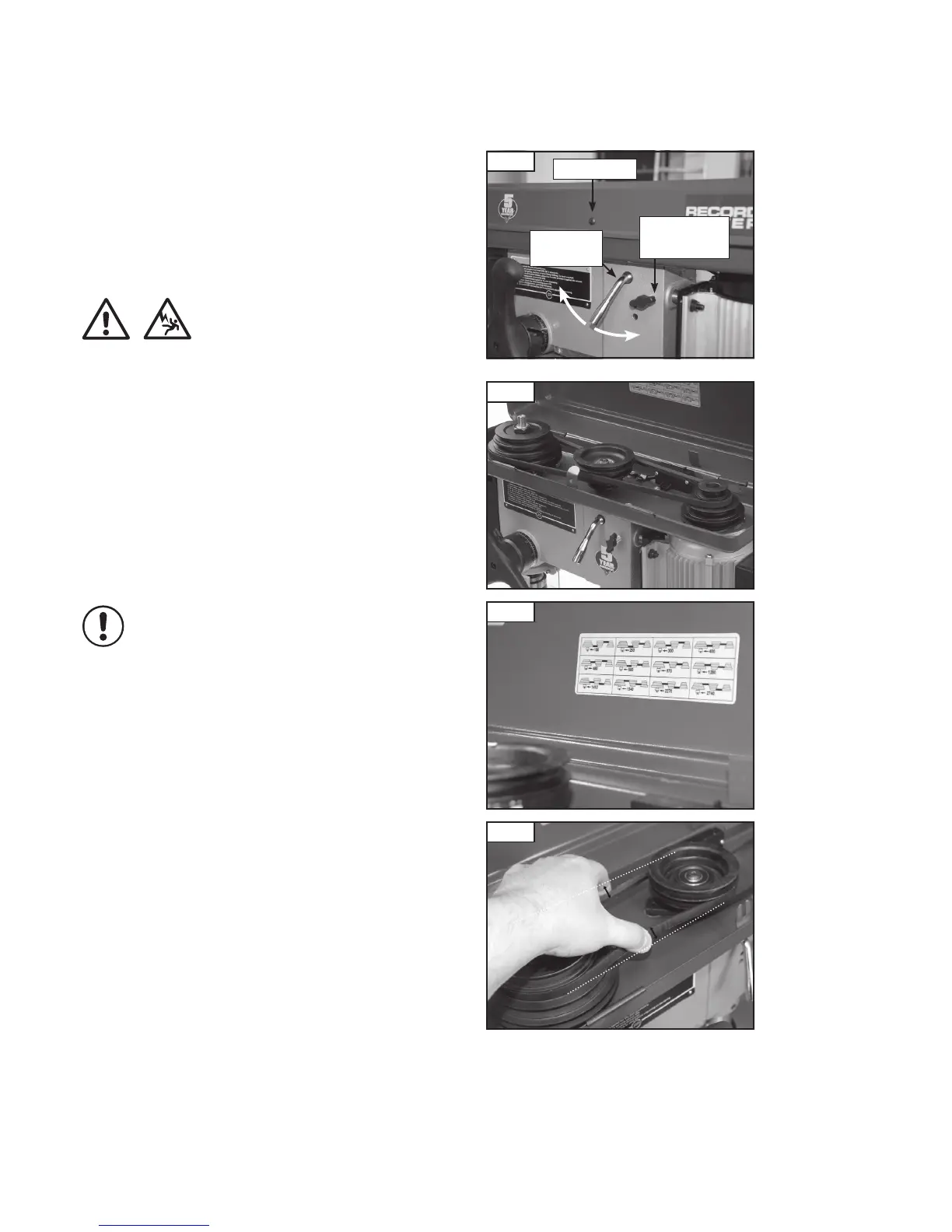

An indication of the correct tension is that when one of the belts is pinched

with reasonable force, each side moves no more than approximately 13 mm

(Fig. 9.4).

Lubrication

This machine uses sealed bearing units which require no maintenance for

the life of the product.

The table elevation mechanism and the splines (grooves) in the spindle

pulley system may need to lubricated periodically.

Fig. 9.2

Fig. 9.4

13 mm

maximum

13 mm

maximum

Fig. 9.3

Fig. 9.1

Loading...

Loading...