INSTALLATION

1. Inspection of Valve

Check inside diameter of pipe section for rough or damaged

areas. Surface should be uniform and relatively smooth. Long

gouges or cracks may allow water to pass and should be lled

prior to installation. The exterior of the Series 37G should

have a rough texture resembling a cloth pattern. This will help

the valve grip the walls of the pipe.

2. Valve Orientation

The valve shall be installed with the bill in the vertical position.

Valves to 18" (nominal) are supplied with a single clamp. The

clamp turnbuckle should be oriented at top dead center.

Valves 24"—48" (nominal) are supplied with two clamps. The

turnbuckles should be oriented 180˚ apart. Valves 60"—72"

(nominal) are supplied with three clamps. Turnbuckles should

be oriented 120˚ apart.

3. Pipe Dimensions

Every Series 37G is designed and built to t into a specic

pipe inside diameter. Different pipe materials such as

concrete, HDPE, steel, and PVC have different. I.D.

dimensions for the same nominal pipe size. Do not attempt

to install a Series 37G into a pipeline for which it was not

intended.

4. Preparation

The Series 37G uses expanding clamp(s) to exert pressure

outwards on the walls of the valve to "wedge" it in place within

the pipe. The walls of the pipe should be clean and free of

debris prior to installation.

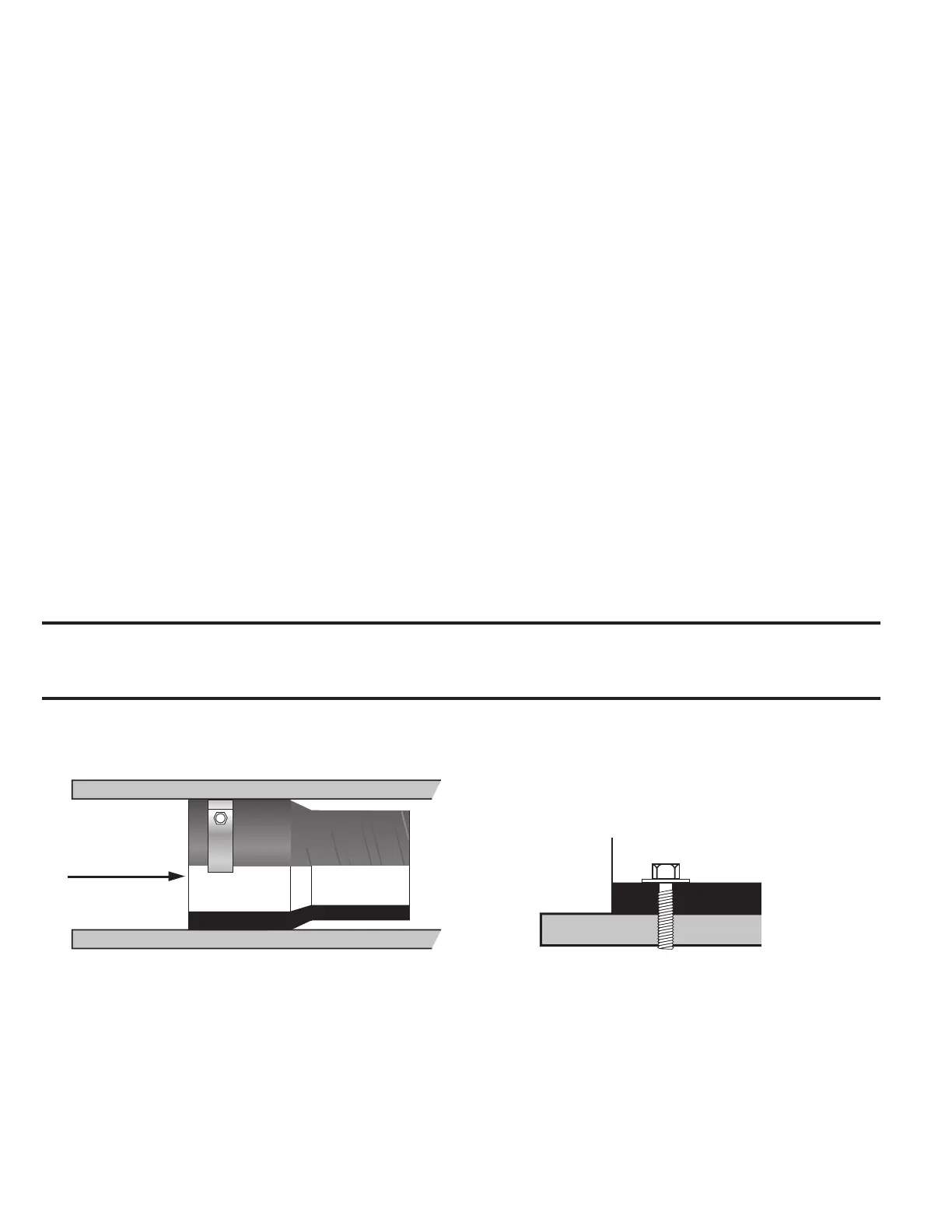

5. Securing

The valve should be inserted fully into the pipe so that no

part of the cuff or bill extends outside the pipe. Ensure that

the valve is not "slanted" at an angle, with the bill pointing

upwards or downwards. The valve centerline should be

parallel to the pipe centerline.

Tideex

®

recommends pinning the Series 37G on all

installations. See below.

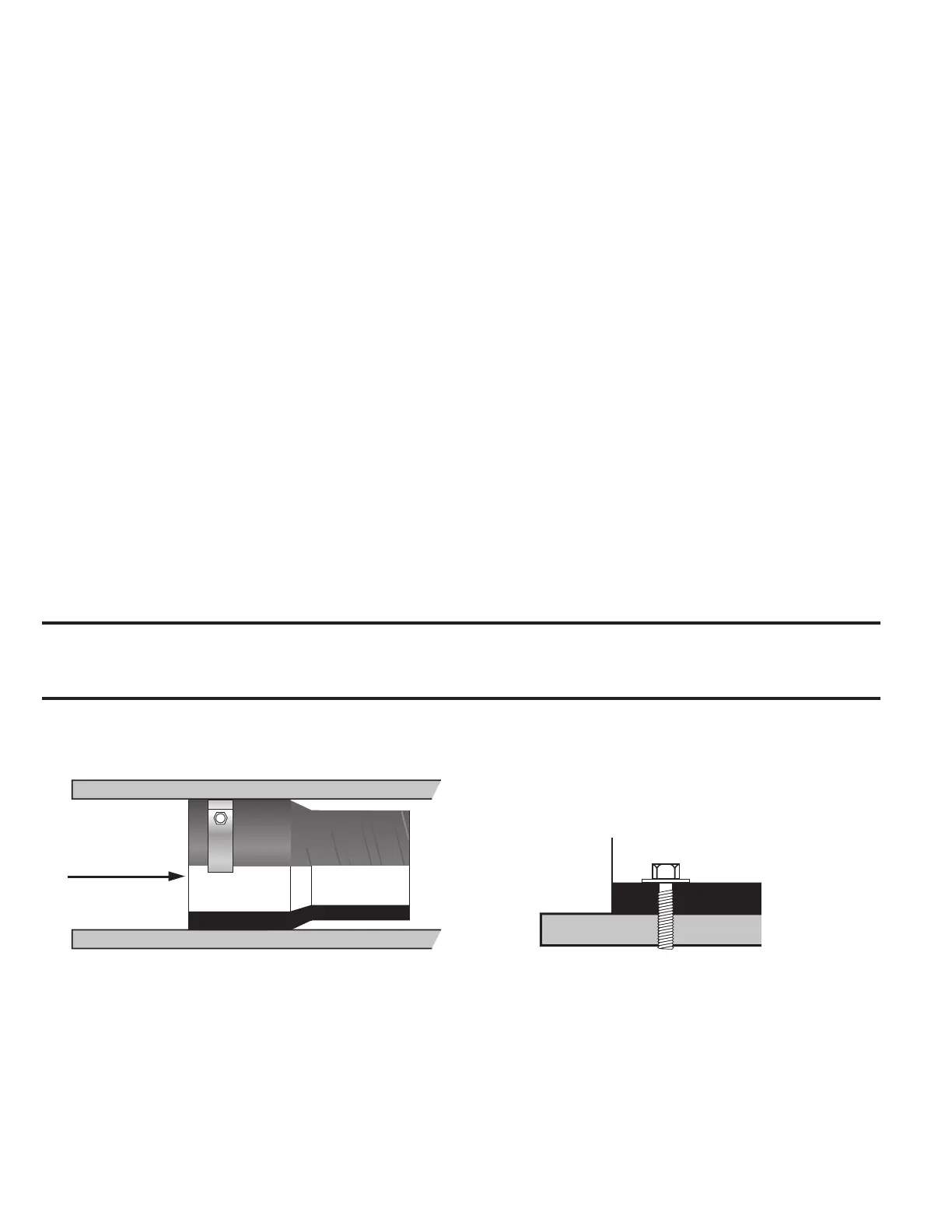

Four pre-drilled holes are provided in each expansion clamp.

At least one clamp should be pinned. On exposed pipe, holes

can be drilled through the valve and pipe, and a bolt run

through secured with a nut. For buried pipe, silicon or similar

sealant should be used to seal bolts.

NEVER...

Install the Valve at

An Angle

NEVER...

Install the Valve

Backwards

NEVER...

Use Sharp Tools on

Rubber

NEVER...

Exceed Design Back Pres-

sure

Loading...

Loading...