166

3. Periodically remove vessel from water and clean/

pressure wash all drive, anode and hull bottom ar-

eas to remove growth.

4. Ensure vessel is using the correct anode metal

for the body of water that it is moored. See the en-

gine manufacturer’s manual for more information

or contact an authorized dealer.

5. Ensure that the drive is completely “in” down

to provide more complete anode protection when

vessel is moored.

6. Do not attempt to use magnesium anodes in

saltwater. They will provide over protection.

7. If marina moored, contact appropriate person-

nel if signs of galvanic corrosion appear on your

drive system. Ask them to check for stray electri-

cal current which may be originating from a nearby

vessel’s faulty DC wiring or from a marina pier, pil-

ing or dock carrying leaking marina ground wiring

such as a dock side cord partially submerged.

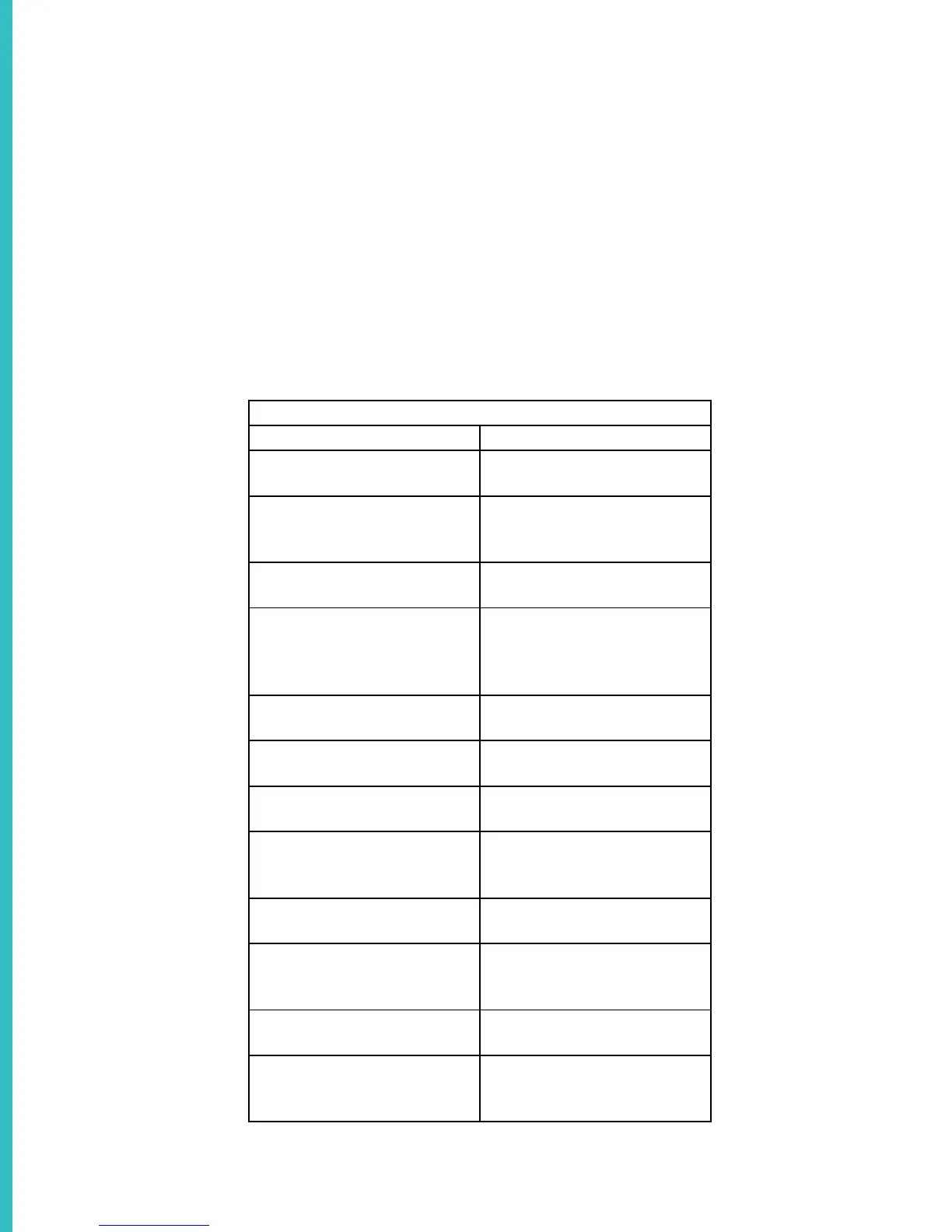

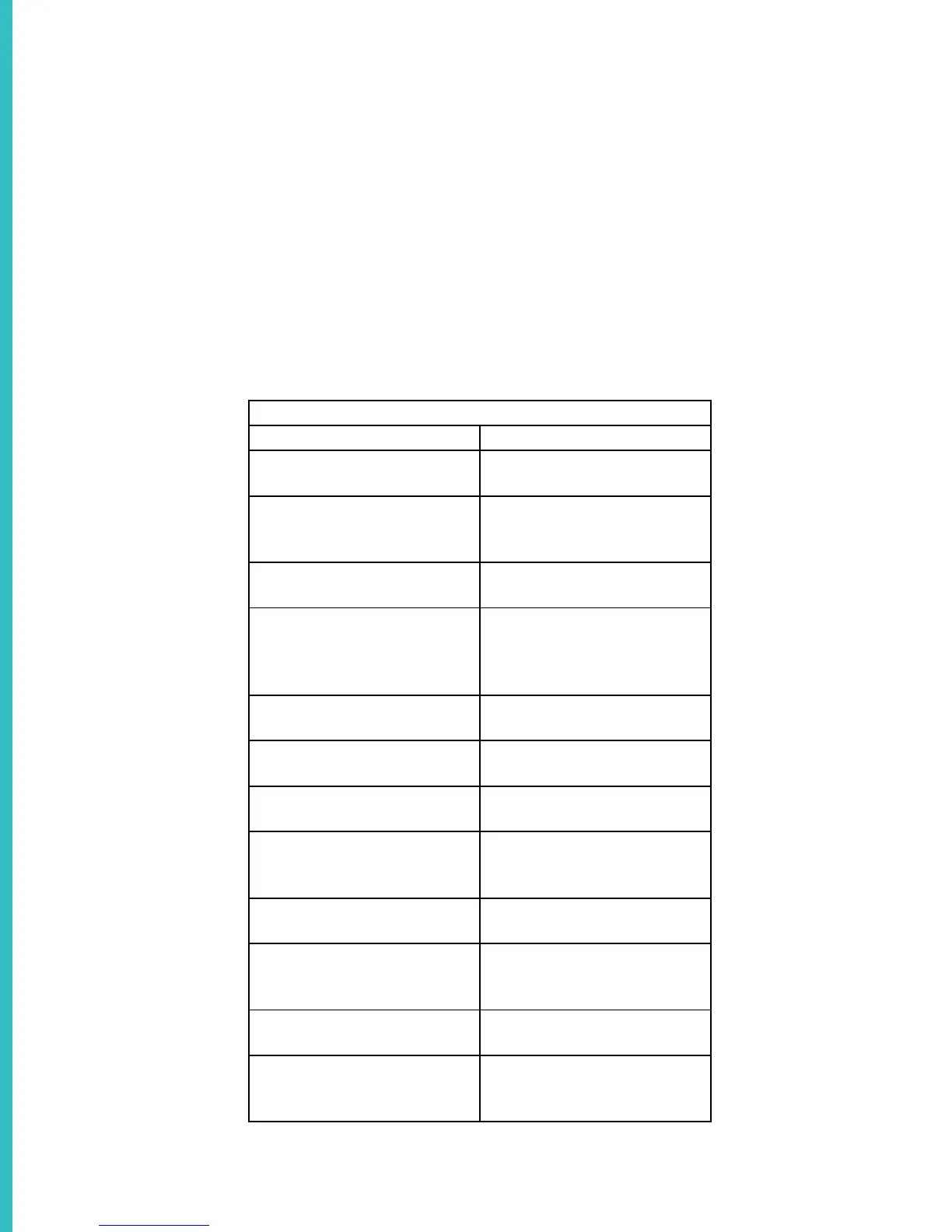

GALVANIC/STRAY CURRENT CORROSION

Cause/Observed Condition Corrective Action

Sacrificial anodes consumed Replace anodes when 30%

consumed

Sacrificial anodes not

grounded to drive

Remove anodes, clean con

-

tact surface, reinstall, check

for continuity

Loss of continuity between

underwater parts & ground

Provide good ground

connections

Nearby vessel with stray

current

Contact appropriate person

-

nel

Remove your vessel from

water

Paint on drive heavily worn,

exposing more metal

Prime and repaint or install

additional anodes

Sacrificial anodes painted Remove paint or replace

anodes

Drive tilted/anodes out of

water

Leave drive down, install ad

-

ditional anodes below water

Power trim cylinders only

corroded

Provide a good ground

to drive, all parts must be

grounded

Corrosion in area of exhaust

outlets

Remove deposits

Corrosion occurring after

vessel is removed from

saltwater

Wash exterior and flush inte

-

rior with freshwater

Stainless steel parts

corroding

Clean parts, remove foreign

material, ensure continuity

Underwater drive parts cor

-

roded, sacrificial anodes OK

Oxide film on anode (fresh

water only) Replace anode

Poor ground. Scrape anode

Loading...

Loading...