NOTE:

There is an

"0"

ring installed in the bearing bore

of

the bearing bracket. Inspect this 0 ring

for wear

or

damage, and replace

if

necessary.

B.

Bearing

Removal

Procedure.

Visually inspect the bearing for obvious wear

or

damage

before removing.

Using a bearing puller, remove

the

bearing.

If

possible, insure that

the

puller is

against the inner race

of

the bearing

to

prevent damaging the bearing.

C.

Bearing

Replacement.

ALWAYS

install the same type and size bearing that was supplied

as original equipment. Order by part number from the parts list, and include the unit serial number

and

part number when ordering. Heat the bearing

to

a maximum

of

212°F in an oven. Apply a thin

coat

of

clean lubricating oil

to

the press-fit area

of

the rotor shaft. Using suitable heat resistant

gloves, install the bearing over the end

of

the shaft until it seats against the shaft shoulder. The

bearing should slide

on

the shaft and

be

seated without excessive force. Should the bearing bind

on

the shaft prior

to

being seated against the shoulder, a piece

of

tubing slightly larger than

the

press-fit

area can

be

used

to

drive the bearing home. Using light taps with a soft mallet, apply pressure

to

the

inner race only.

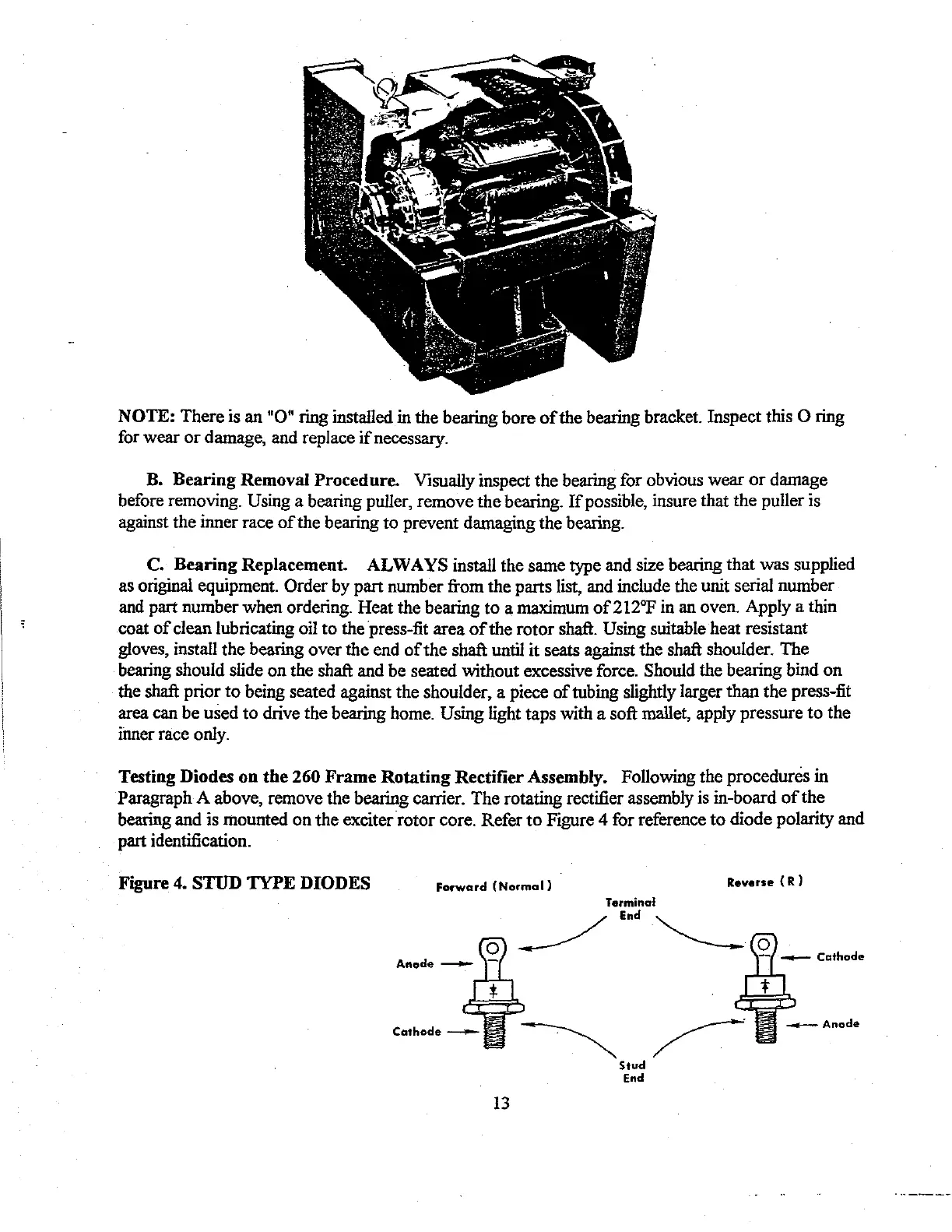

Testing Diodes

on

the

260

Frame

Rotating

Rectifier

Assembly. Following the procedures in

Paragraph A above, remove the

bearing carrier. The rotating rectifier assembly is in-board

of

the

bearing and is mounted

on

the exciter rotor core. Refer

to

Figure 4 for reference

to

diode polarity and

part identification.

Figure 4.

STUD

TYPE

DIODES

Forward

(Normal)

Reverse {

R)

Anode -

Terminal

Q

__/

End

."'----

13

~~

Stud

End

Loading...

Loading...