Maintenance & Trouble Shooting (refer to Fig. 1)

The following table provides a simplified, trouble-shooting guide which indicates the necessary corrective maintenance for the

more common problems, which may occur.

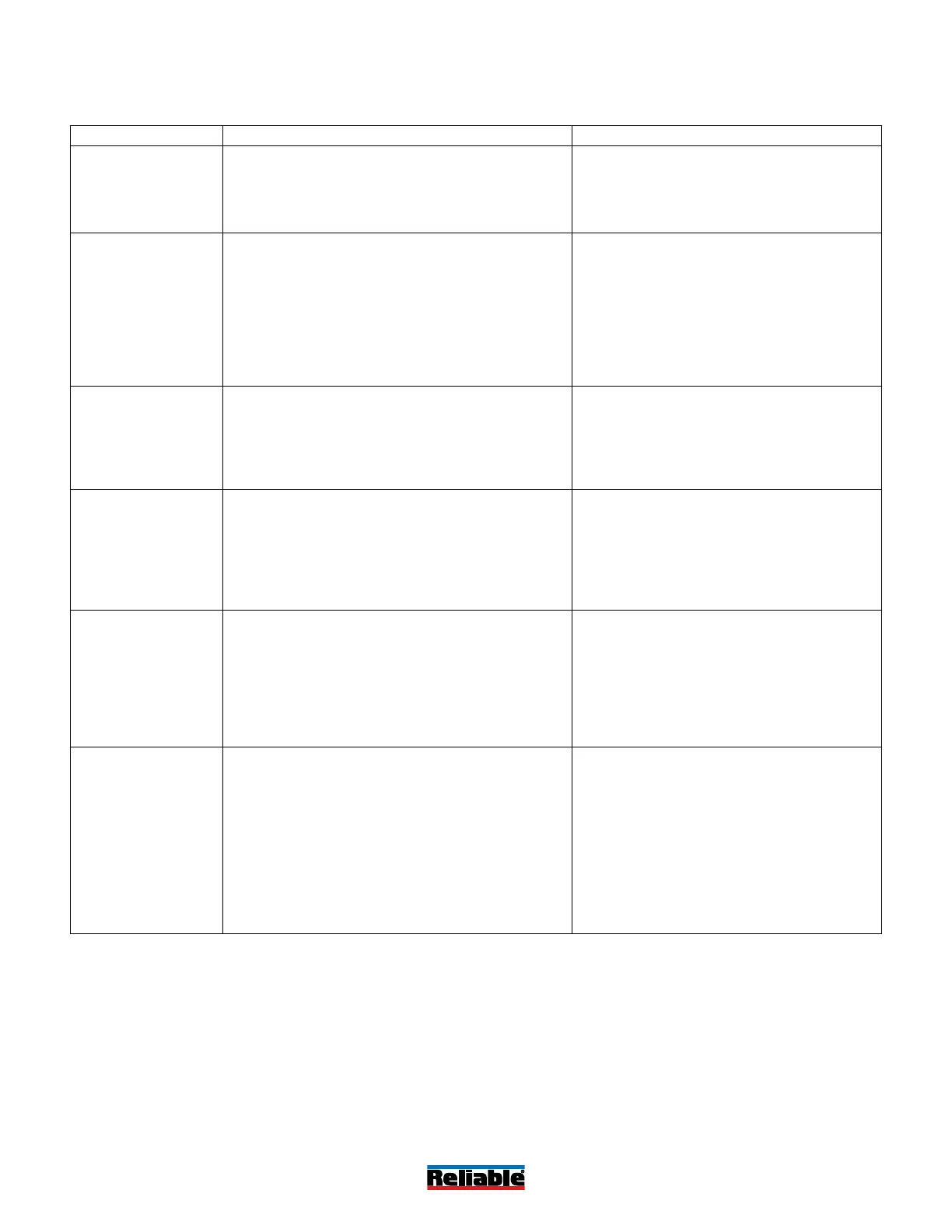

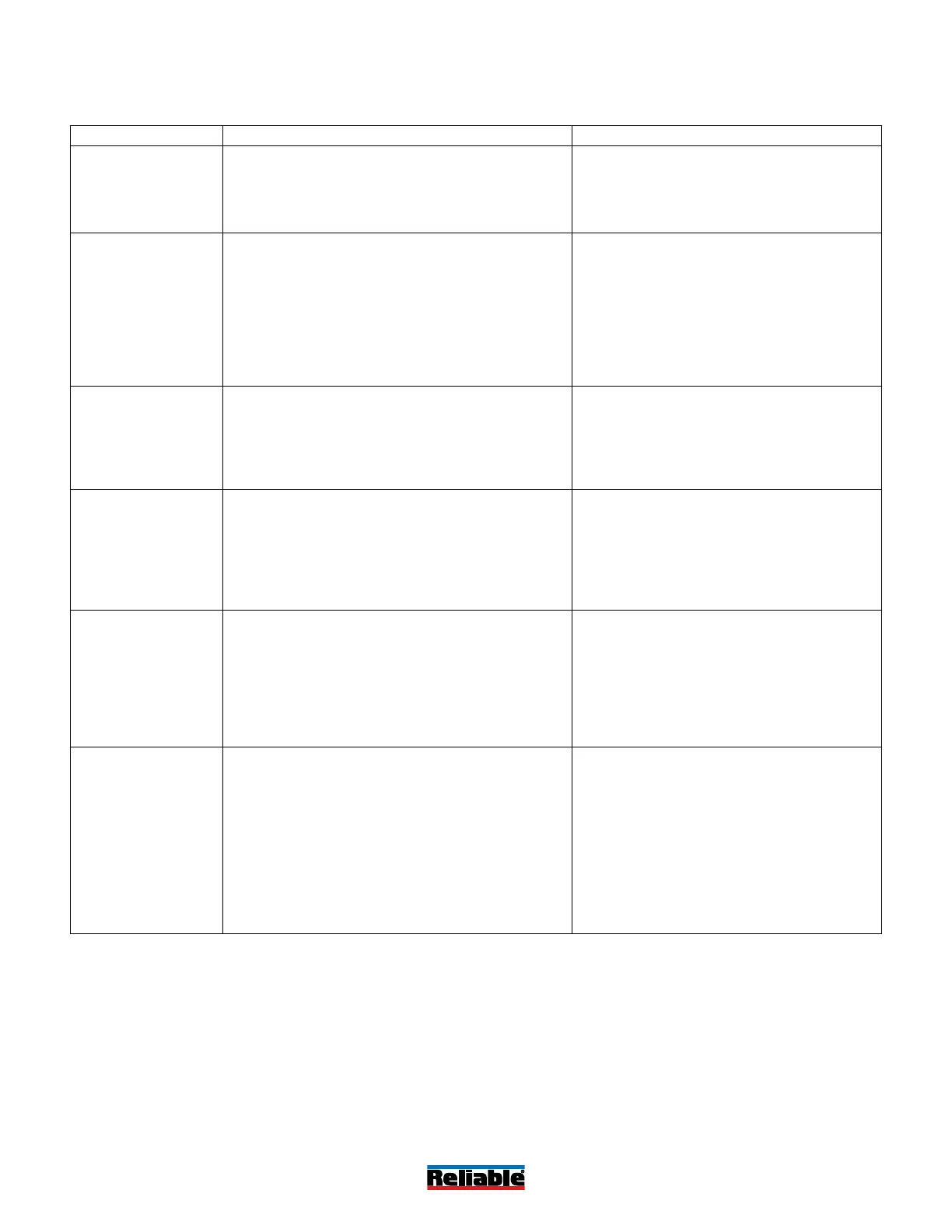

Symptom

Probable Cause Correction

Air flows rapidly

through the

Accelerator and

into the outlet port

when resetting.

The Push-Rod is in the held down position by

contamination, the Push-Rod is bent or the Push-Rod

guide is too tight.

Clean or replace as needed.

Minor air flow or

leakage through

the Accelerator.

1. Contamination in the poppet area.

2. The Poppet “O”-Ring has blown off the Poppet,

or is cut.

3. The Accelo-Check diaphragm has a hole or

rip allowing air to reach the outlet through

passageway (F).

4. Leakage past the Push-Rod Guide “O”-Ring.

5. The Push Rod or Push-Rod Guides damaged

causing leakage.

1. Clean.

2. Install new “O”-Ring.

3. Replace.

4. Replace.

5. Replace.

No or low air pressure

in the top chamber

(gauge pressure

does not increase,

and no air pressure

in the outlet).

1. Filter assembly is clogged.

2. Restriction area (Passageway G) is clogged or

the filter on the diaphragm nut is clogged.

1. Replace

2. Replace.

Accelerator will not trip

during a system test.

1. The top chamber air pressure is bleeding back to

the system too fast through restriction area.

2. The top chamber air pressure is bleeding back to

the system through the ripped diaphragm.

3. External leak in top chamber.

4. Filter assembly restricted.

1. Clean the top of the Push-Rod and mating

surface in diaphragm nut, or replace.

2. Replace

3. Check the gauge and the drain plug for

tightness-use new PTFE tape on the plug

after each resetting.

4. Replace.

Accelerator floods with

water.

1. Inspect check valve for leakage when system is

filled with water.

2. The Accelo-Check “O”-Ring is missing or cut.

3. Leakage past the Push-Rod Guide “O”-Ring.

4. Push rod or Push-Rod Guide is

damaged allowing leakage.

5. Condensate from the compressor

has not been drained.

1. Wipe off the clapper facing and seat

clean.

2. Replace if necessary.

3. Replace.

4. Replace.

5. Drain water from compressor and air

supply line.

Accelerator operates

prematurely.

1. Water or dirt in the restriction area.

2. Air is not bleeding back through the restriction

area to compensate for minor pressure

fluctuations.

3. Dry pipe valve is operating prematurely - not the

accelerator.

4. On-Off is setting of the compressor’s pressure

switch allowing the system pressure to decay

too far.

1. Clean top of the Push-Rod and mating

surface-perform sensitivity test.

2. Replace Push-Rod and / or diaphragm

nut. In “Test” section of this Technical

Bulletin - perform sensitivity test.

3. Review the correct pressure settings from

the corresponding system’s technical

bulletin.

4. Readjust the differential of pressure

switch to minimum (6-8 psi) when using

an accelerator.

Bulletin 323

May 2019

Page 5 of 7

www.reliablesprinkler.com

Loading...

Loading...