7.

Hydrostatically testing the valve and trim to pressures

higher than their rating is limited to the hydrostatic

test as referenced by NFPA 13. It does not address the

occurrence(s) of a “water hammer” effect, which can in-

deed damage the valve. A “water hammer” in the water

supply piping of the valve can create pressures in ex-

cess of the rated pressure and should be avoided by all

necessary means. This condition may be created from

improper re pump settings, underground construction

work, or an improper venting of trapped air in the water

supply piping.

System Design Considerations

The automatic sprinklers, wet pilot line detectors, and sig-

naling devices which are utilized with the Wet Pilot Line Single

Interlock Preaction System must be UL or ULC Listed, as ap-

plicable.

The automatic sprinklers, air compressor, releasing devices,

electric releasing control equipment, re detection devices,

manual pull stations, and signaling devices which are utilized

with the Electric Actuation Single Interlock Preaction System

must be UL or ULC Listed or FM Approved, as applicable.

The automatic sprinklers, air compressor, releasing devices,

electric releasing control equipment, re detection devices,

manual pull stations, and signaling devices which are utilized

with the Dry Pilot Line Single Interlock Preaction System must

be UL or ULC Listed, as applicable.

The Deluge Valve, and all interconnecting piping must be

located in a readily visible and accessible location and in an

area that can be maintained at a minimum temperature of 40°F

(4°C). Note: Heat tracing is not permitted.

Pendent sprinklers, other than dry pendents, used on preaction

systems shall be installed on return bends per NFPA 13.

For Electric Actuation Single Interlock Preaction Systems, the

solenoid valve must be operated and the system supervised by

a listed releasing control panel.

In Wet Pilot Line Single Interlock Preaction Systems, the wet

pilot line is only a detection system and does not contribute to

controlling the re. Wet pilot line installation is subject to the fol-

lowing restrictions:

a. It is not to be installed in an area subject to freezing.

b. It is not to be installed in an area where temperatures

in excess of 150°F (65°C) are anticipated.

c. NFPA 72 or the authority having jurisdiction should be

consulted for spacing and elevation requirements.

d. Maximum wet pilot line length and height must comply

with data provided in Fig. 2.

For Dry Pilot Line Single Interlock Preaction Systems, the

detector must be installed only in an upright position.

System Air Pressure Requirements

For Wet Pilot Single Interlock Preaction Systems and

Electric Actuation Single Interlock Preaction Systems, a

Reliable Model B-SI Air Compressor Panel or Reliable Model

C-SI Air Compressor Panel can be used to maintain the system

air pressure at approximately 7 psi (0.5 bar). The air compres-

sor panels contain an integral low air pressure warning light.

In some circumstances, such as when dry sprinklers are be-

ing used in a preaction system, it may be desirable to super-

vise the preaction system at air pressures higher than 7 psi

(0.5 bar). For such cases, Reliable recommends the use of a

tank-mounted compressor and the Reliable Model A Pressure

Maintenance Device. Supervising pressure may be between 7

psi and 20 psi (0.5 and 1.4 bar).

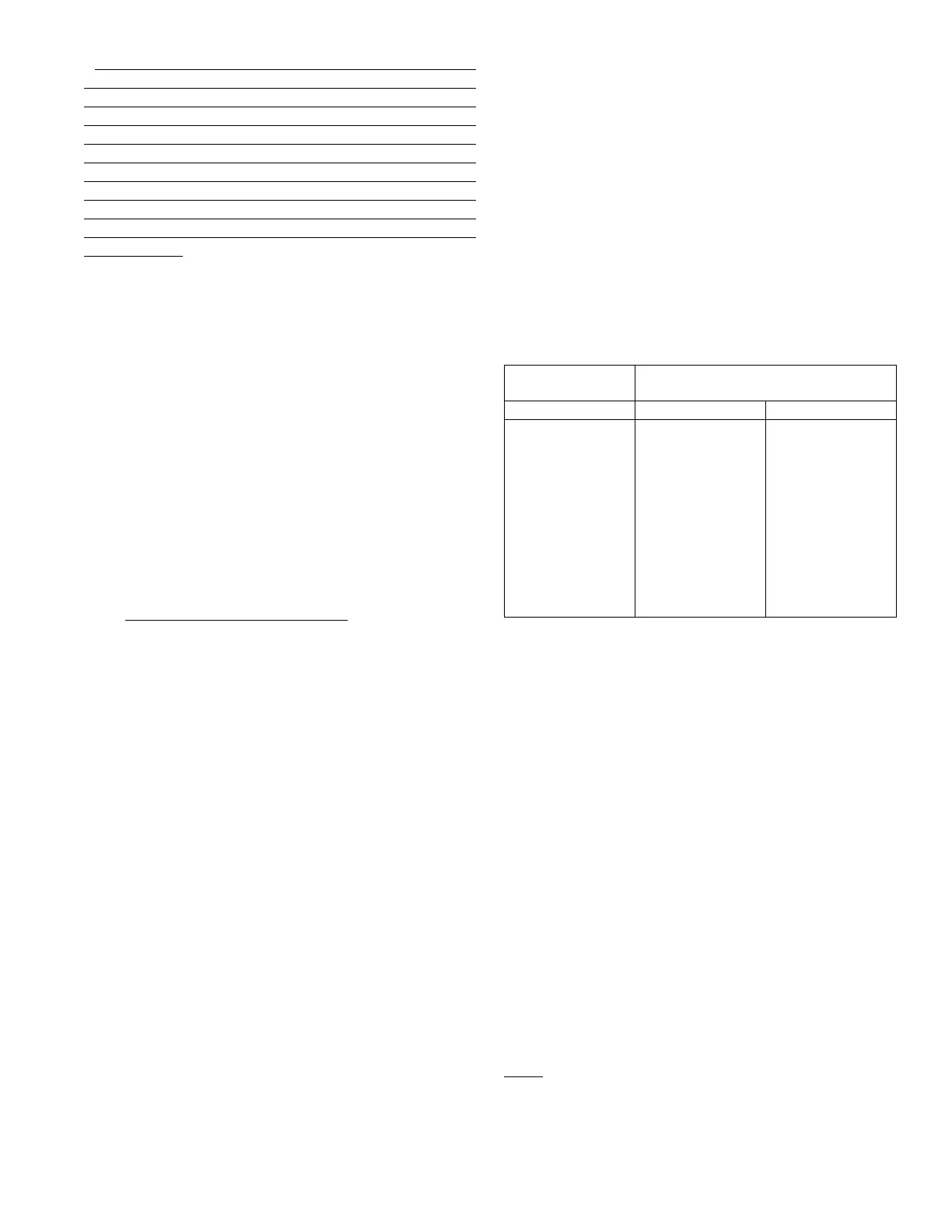

For Dry Pilot Line Single Interlock Preaction Systems, a

Reliable Model A Pressure Maintenance Device can be used

to maintain the pneumatic pressure of both the Dry Pilot Line

of detectors and the re sprinklers to the values shown in Table

A. The values listed in the table represent the necessary ranges

of pneumatic pressure required to keep the Model LP Dry Pilot

Line Actuator in the closed position for a given water supply

pressure.

Table A

Water Pressure

psi (bar)

Pneumatic Pressure to be Pumped

into Sprinkler System psi (bar)

Maximum Not Less Than Not More Than

20 (1.4)

30 (2.1)

50 (3.4)

75 (5.2)

100 (6.9)

125 (8.6)

150 (10.3)

175 (12.1)

200 (13.8)

225 (15.5)

250 (17.2)

275 (19.0)

300 (20.7)

8 (0.6)

10 (0.7)

12 (0.8)

13 (0.9)

15 (1.0)

16 (1.1)

17 (1.2)

18 (1.2)

19 (1.3)

21 (1.4)

22 (1.5)

23 (1.6)

24 (1.7)

10 (.7)

14 (1.0)

16 (1.1)

17 (1.2)

19 (1.3)

20 (1.4)

21 (1.4)

22 (1.5)

23 (1.6)

25 (1.7)

26 (1.8)

27 (1.9)

28 (1.9)

Note: During system set-up, a higher pneumatic pressure

may be required in order to properly set the Model LP Dry

Pilot Line Actuator.

Whenever multiple systems area supplied by a common air

or nitrogen source, each system must have its own pressure

maintenance device for individual maintenance of pressure

(NFPA 13, 7.2.6.5).

System Electrical Requirements

When Using the Electric Actuation Single Interlock Preaction

System, all releasing, alarm and detection devices in the Single

Interlock Preaction System may be supervised by the Potter

PFC-4410-RC Releasing Control Panel. The panel should be

set to use Program #6 for single zone detection or Program

#7 for cross-zone detection (See Potter Instruction Manual

#5403550).

The power supply, the standby emergency power supply, bat-

tery charger, and the rectier circuitry are all contained within

the Potter PFC-4410-RC Releasing Control Panel. The solenoid

valve is operated and supervised by the Potter PFC-4410-RC

Releasing Control Panel. Potter PFC-4410-RC Releasing Con-

trol Panel requires 120 VAC. Batteries that provide ninety hours

of standby power are required for Factory Mutual Approved

systems.

Note:

In order for the solenoid valve to maintain Reliable’s warranty

it must remain sealed as it came from the factory. If there are

concerns about the valve’s internal components, immediate

replacement is recommended.

Loading...

Loading...