11.

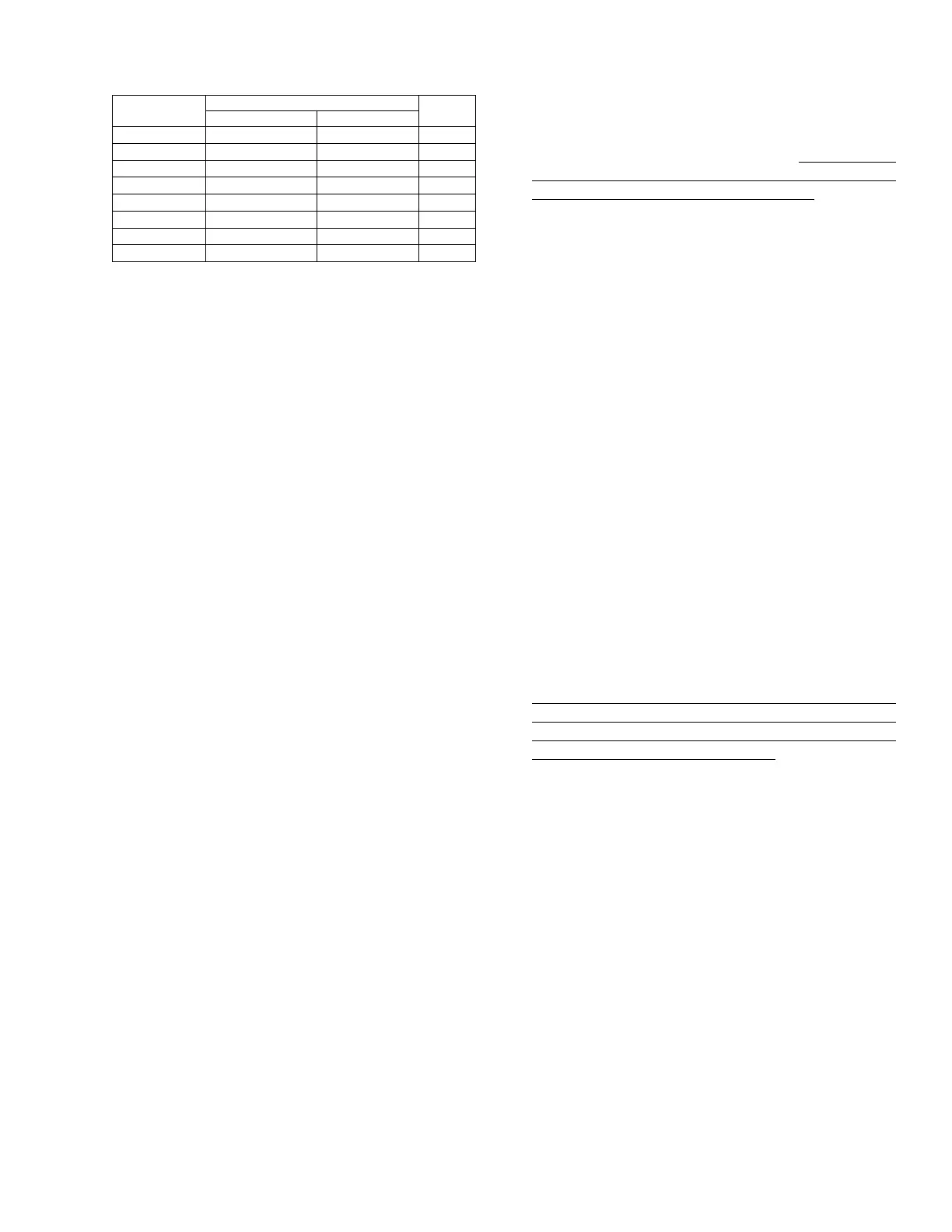

8. Friction loss (Expressed in equivalent length of Schedule

40 pipe, based on Hazen & Williams formula:

Valve Size:

Equivalent Length:

Cv

C = 120 C = 100

2" (50mm) 4.4 ft (1,3 m) 3.1 ft (1,0 m) 101

2½" (65mm) 6.0 ft (1,8 m) 4.3 ft (1,3 m) 236

76mm 7.7 ft (2,3 m) 5.5 ft (1,7 m) 241

3" (80mm) 12.6 ft (3,8 m) 9.0 ft (2,7 m) 254

4" (100mm) 14 ft (4,3 m) 10 ft (3,0 m) 469

165mm 29.4 ft (9,0 m) 20.9 ft (6,4 m) 886

6" (150mm) 29.4 ft (9,0 m) 20.9 ft (6,4 m) 886

8" (200mm) 53.5 ft (16,3 m) 38.1 ft (11,6 m) 1516

9. Installation position: Vertical ONLY.

Trim Descriptions

The Single Interlock Preaction Trims for the Reliable Model

DDX Deluge Valve are arranged for rapid, easy, and compact

attachment, and serve as connection points to Reliable Model

C Mechanical Alarms and other devices.

The available Model DDX Single Interlock Preaction System

trim sets are:

• Wet Pilot Line Single Interlock Preaction Trim

• Dry Pilot Line Single Interlock Preaction Trim

• Electric Actuation Single Interlock Preaction Trim

All three trim congurations can be ordered as individual

parts, in time-saving segmentally assembled kit forms, or fully

assembled to the Model DDX Deluge Valve (with or without a

control valve).

The Model B Hydraulic Manual Emergency Station is a stan-

dard item of all Deluge Valve trim sets. It consists of an alumi-

num nameplate mechanically attached to a ball valve. The valve

handle in its OFF position is guarded against accidental turning

to the ON position (and system discharge) by a nylon cable tie

provided with each trim kit. The cable tie is inserted, after the

system has been restored for operation. The nylon cable tie is

designed to allow, in case of an emergency, forceful turning of

the valve handle to the ON position. As an alternative to the

Model B Hydraulic Manual Emergency Station, the Model A

Hydraulic Manual Emergency Pull Box (see Bulletin 506) is also

available and can be provided as an option.

Model F1-FTR xed temperature pilot line detectors and

spacing requirements are described in Bulletin 180.

Maintenance

Reliable Single Interlock Preaction Systems and associated

equipment shall periodically be given a thorough inspection

and test. NFPA 25, Inspection, Testing and Maintenance of

Water Based Fire Protection Systems, provides minimum main-

tenance requirements. System components shall be tested,

operated, cleaned, and inspected at least annually, and parts

replaced as required.

Resetting Model DDX Single Interlock

Preaction Systems

1. Close the valve controlling water supply to the Deluge Valve

and close the air or nitrogen supply to the sprinkler system.

2. Close the pushrod chamber supply valve.

3. Open main drain valve and drain system.

4. Open all drain valves and vents at low points throughout the

system, closing them when flow of water has stopped. Open

the Model B Manual Emergency Station to relieve pressure in

the pushrod chamber of the Deluge Valve.

5. With the alarm line valve open, push in the plunger of ball drip

valve, forcing the ball from its seat, and drain the alarm line.

6. With the Model B Manual Emergency Station open, push in

and rotate the Deluge Valve’s external reset knob counter-

clockwise (when facing the valve), until you hear a distinct

noise indicating that the clapper has reset. Note: The reset

knob can be rotated only while pressure in the pushrod cham-

ber is vented to atmospheric conditions (0 psig).

7. Inspect and replace any portion of the detection system and/or

sprinkler system subjected to re conditions.

8. Open the pushrod chamber supply valve and allow water to ll

the pushrod chamber. Close the Model B Manual Emergency

Station .

9. Bleed all air from the actuation piping:

A. Wet Pilot Line Single Interlock Preaction Trim—bleed the

entire wet pilot line until all air is removed at the most

remote sprinkler.

B. Electric Actuation Single Interlock Preaction Trim—open

the solenoid valve by operating a detector or an elec-

tric manual emergency station. While water is flowing

through the solenoid valve, cause it to close using the

release control panel reset.

C. Dry Pilot Line Single Interlock Preaction Trim— If pres-

surized, remove pneumatic pressure from Model LP Dry

Pilot Actuator, allowing water to flow through the actua-

tor. When all air has been expelled from the release line,

and there is a solid flow of water into the drain cup , apply

compressed air or nitrogen through the pressure main-

tenance device to close the pilot line actuator. Adjust the

air or nitrogen pressure to the appropriate value in Table

A as indicated on air pressure gauge.

10. Close the alarm line valve. Open the air or nitrogen supply

quick ll valve to restore supervisory pressure in the sprinkler

system, then set the pneumatic supply to automatic operation.

Note: To build supervisory air pressure in the sprinkler

system, it may be necessary to temporarily close the

main drain valve until air pressure has built up to the

manufacturers recommended levels.

11. Open the alarm line valve. Verify the main drain valve is open.

Open slightly the main valve controlling water supply to the

Model DDX Deluge Valve, closing the main drain valve when

water flows. Observe if water leaks through the ball drip valve

into the drip cup . If no leak occurs, the Deluge Valve clapper is

sealed. Open slowly and verify the main valve controlling water

supply is fully opened and properly monitored.

12. Verify that the pushrod chamber supply valve and alarm line

valve are open. The pushrod chamber supply valve must

remain open when the Deluge Valve has been reset, to

maintain water pressure in the pushrod chamber.

13. Verify that the Model B Manual Emergency Station is secured

in the OFF position with the appropriate nylon tie.

Inspection and Testing

1. Water supply — Conrm that valves controlling water supply

to the Deluge Valve are opened fully and properly monitored.

2. Alarm line — Conrm that the alarm line valve is open and

remains in this position.

Loading...

Loading...