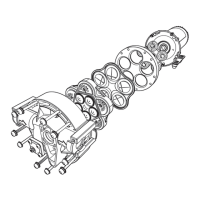

55AQUAJET-AES – 3.4 GPM/12VDC, WITH FUSE

55AQUAJET-OES – 3.4 GPM/12VDC, NO FUSE

55AQUAJET-ARV – 5.0 GPM/12VDC, WITH FUSE

55AQUAJET-ORV – 5.0 GPM/12VDC, NO FUSE

RV Water System Pumps

1. Never operate the pump in an atmosphere where flammable gases may be present, since arcing at the motor brushes or

switch contacts may cause an explosion.

2. After extended operation, or if malfunctioning, metal surfaces of the pump may become hot and cause burns if touched. If this

occurs, disconnect electrical power and wait 30 minutes before touching pump.

3. Never mount the pump where the surface temperature of the motor or the controller (200° F maximum) may cause ignition of

the surrounding materials.

4. Do not wrap the pump with an insulating material or enclose it so tightly that air circulation around the pump is prevented. The

pump will generate approximately the same amount of heat as a 75 watt light bulb.

5. The pump should be mounted in a dry location away from any heat and water source(s).

6. Pumphead materials are designed for use with water only and should never be used with petroleum products. Chlorine will

deteriorate the parts in the pump. Always rinse the system with fresh water after sanitizing to help prolong the life of the parts.

7. The pump is equipped with a pressure sensing demand switch which controls the maximum operating pressure as set at the

factory. Never subject the pump to pressures above 90 PSI maximum. This switch should never be adjusted without consulting

factory.

8. Always consider electrical shock hazards when working with and handling electrical equipment. If uncertain in your abilities,

please consult an electrician.

9. 55Aquajet ORV, OES, ARV and AES Series pumps are equipped with an automatically resetting thermal protector. If a pump is

not running, it may restart at any time.

10. Both the 55Aquajet ARV and AES Series include a fuse-holder. It is important to use only a 15 amp AGC automotive type fuse

for the Aquajet RV Series and a 10 amp AGC fuse for the Aquajet ES Series. Once again, use only these types of fuses with

these specific pumps.

11. It is necessary to use a screen filter between the water holding tank and the pump to prevent debris from entering the pump.

Particulate matter may cause the valves inside the pump to stick open. This filter needs to be cleaned on a regular basis, or it

will restrict water to the pump.

12. Winterizing the pump: If water is not drained from the system during freezing temperatures, damage to the pump and the

plumbing is likely:

a. Drain the water holding tank.

b. Chlorine will deteriorate the parts in the pump. Always rinse the system with fresh water after sanitizing to help prolong

the life of the parts.

c. Open all faucets and run the pump to expel all water.

d. Disconnect inlet and outlet fittings and run pump to remove residual water from the pump.

e. Leave fittings disconnected from pump.

Installer qualifications

If you intend to install an Aquajet Series pump without professional assistance, you should clearly be “handyman” competent

enough to do simple low voltage electrical wiring, crimp connectors, obtain voltage measurements, understand polarity as well as

schematics which illustrate relay connections. Additionally, you should be comfortable with water system plumbing, installing hose

clamps, using Teflon tape, and removing/re-tightening compression fittings.

The 5-chamber Aquajet Series pumps are more powerful than most existing RV water pumps and, as a result, may draw more

current (Amps) than the pump(s) they replace. It is imperative that any power supply, fuses/circuit breakers, wiring, switches,

connectors, or controllers that are used to supply 12 VDC to the pump are adequately sized. Inadequately sized components may

overheat, causing an electrical fire.

When installing an Aquajet Series pump, positive voltage (+12VDC) must be connected to the Aquajet’s red fused leadwire.

Reversing polarity will instantly blow the fuse and may permanently damage the controller.

If you are uncertain with respect to any of this information, Remco highly recommends that a qualified technician perform your

installation and determine the existing polarity of your current wiring.

Please read the following instructions before attempting an installation. When properly installed, Aquajet Series pumps can

be used in virtually any existing RV.

If you prefer to have the pump professionally installed, contact Remco (1-800-228-2481) to locate your nearest authorized

service center.

AQUAJET™ SERIES PUMPS

Operational and Installation Guidelines

www.remcoindustries.com Aquajet Manual - 2022

Warning

Maintenance Tips