21

The following electrical connections must be made:

◊ Connecting the power supply

◊ Connecting the cable remote control if applicable

Please follow the instructions below to install the electri-

cal connections:

◊ The inner units function independently of the chiller.

An electrical control line is hence not necessary.

◊ The electrical connections are to be performed as

fixed connections in accordance with the relevant

regulations.

◊ An all-polo separating switch is to be installed in the

power line in front of the unit.

◊ The power line must be insulated adequately by the

customer and the line drop may not fall below the

permissible values.

◊ Make sure that the electrical system is suitable to

supply the required operating current for operating

the unit and any other units that are already in opera-

tion.

◊ Prior to installation, if connections are made to exist-

ing system parts, you must check that the line has

the right dimensions for unit consumption.

◊ The units must always be connected with low-ohm

protection conductors with sufficient dimensions. In

certain circumstances, the module must be grounded

as a measure to protect against lightning in several

places (especially when plastic pipes are used).

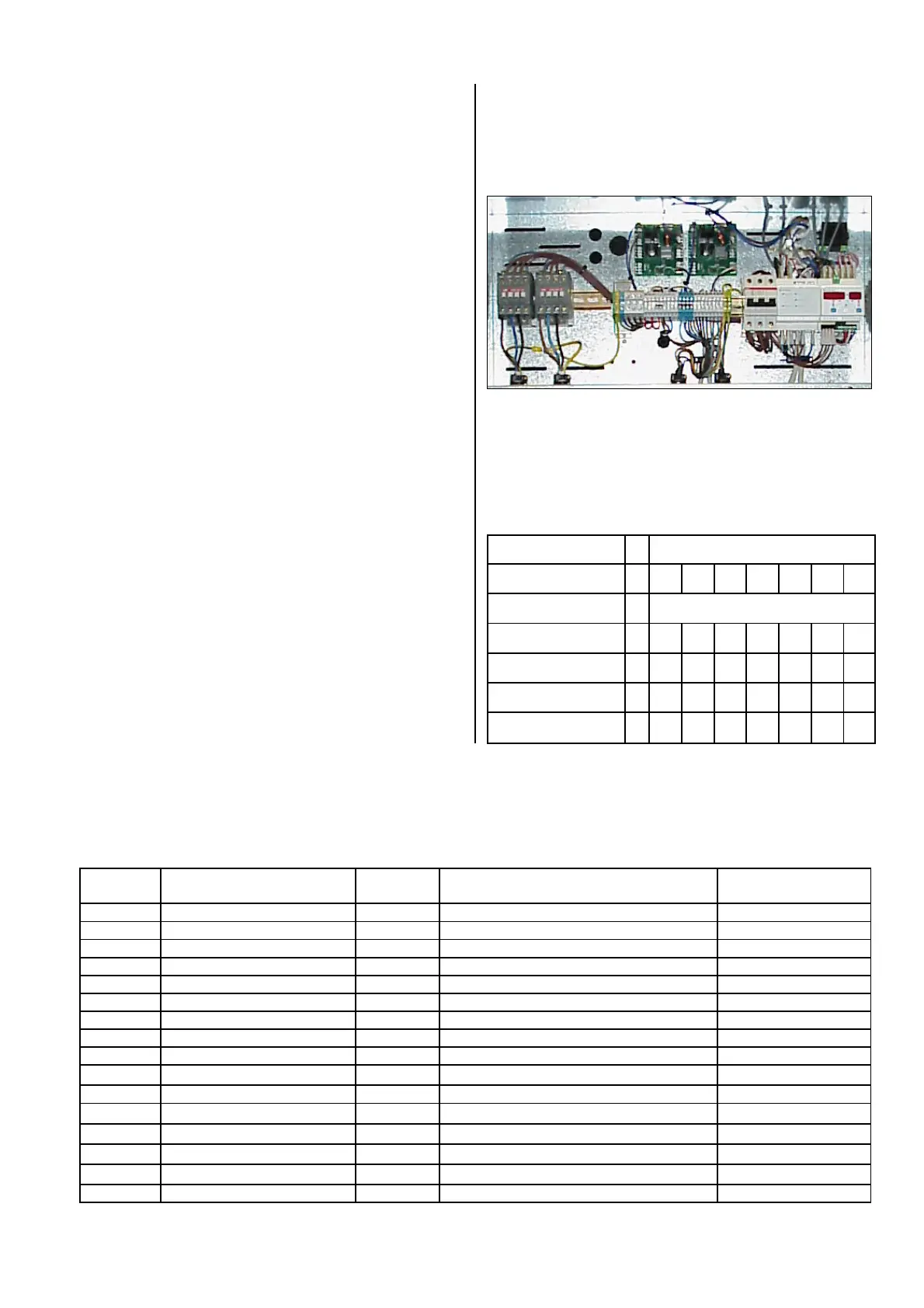

Terminal

strip

Normal status

Input /

Output

Function Connections

01 – 02

ST 1 Incoming water - Sensor PTC - input

03 – 04

ST 2 Outgoing water – Sensor PTC - input

05 – 06

ST 5 Condenser – Sensor PTC - input

07 – 08

closed AT 1 High pressure switch Neutral contact

09 – 10

closed AT 3 Low pressure switch Neutral contact

11 – 12

closed AT 5 Not in use Neutral contact

13 – 14

12 V ~ Tr Current supply 12 V ~, 50 Hz

15 – 16

Closed when pump is in operation AT 9 Differential pressure monitor Neutral contact

15 – 17

AT 7 Heating-cooling removed Neutral contact

15 – 18

closed AT 10 On Off, remote control contact for heating pump Neutral contact

19 – 20

RL 1 Global shut-off Max. 48 V ~, 200 mA

22 – 23

RL 2 Defrost heating / Boiler signal 230 V ~, 50 Hz, 4,0 A

22 – 24

RL 4 Compressor 230 V ~, 50 Hz, 0,4 A

22 – 25

RL 8 Circulation valve (heating pump only) 230 V ~, 50 Hz, 0,4 A,

21 – 22

RL 10 Pump switch contact 230 V ~, 50 Hz, 4,0 A

42 – 43

TK 1 Fan regulation - output Phase regulation

Description of the CH-DIN inputs and outputs

All electrical connections such as power input, cable re-

mote control, etc., are to be made in the switch box of

the unit. The lines to be laid must be guided through the

appropriate cable penetrations on the back of the unit

into the housing.

All units require a three-phase alternating current con-

nection. The power line is to be guided through the L1,

L2, L3, N and PE terminal strips.

The line dimensions are based on the local conditions.

The connection capacity of units can be found in the ta-

ble below:

Type

RKW INOX

1000 1600 2600 3600 4500 8000 9800

Electrical connection

400 V /3~, N. PE / 50 Hz

Power consumption kW

4.4 7.1 11.2 15.7 19.4 36.0 45.2

Cur. Consumption max. A

8 12.8 18.8 26.3 32.6 58.5 73.5

Start-up current A

49 101 167 2x90 2x120 2x116 2x127

Fuse protection

customer-side

A

20 20 25 35 50 80 100

Electrical Connection

G

Warning! The units are equipped with a phase-sequencer relay that prevents the unit from operating if the ro-

tational direction of the electrical connection is wrong. If the chiller remains neutral (i.e. no current) when be-

ing put into operation, the rotational field must be switched.

G

Electrical installations may only be performed by

authorised service personnel. Prior to performing

any work on the unit, it must be unplugged from

the power supply.

Loading...

Loading...