2/25/2013 Retsch GmbH 21 0002

General

Cleaning

TG200

The TG200 should be cleaned only with brushes, and possibly

with an industrial vacuum cleaner or with compressed air.

The system of protection for the TG200 with drying vessel

and clamping lid is IP43.

Without vessel and lid this is reduced to IP22.

Do not clean the TG200 with running water.

Danger to life through current surge.

Filter bags

The filter bags can be washed out under running water.

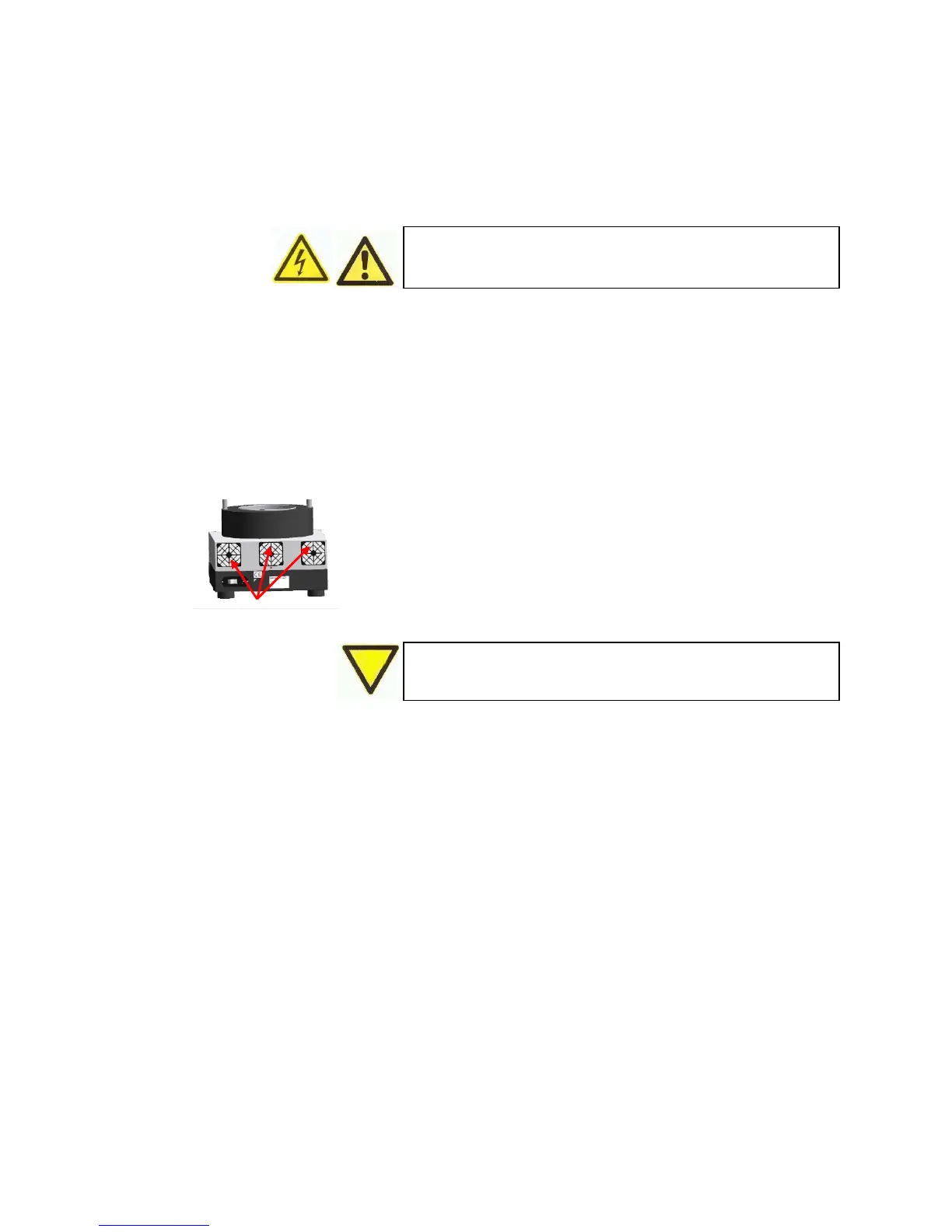

Filter elements and filter on the machine rear side

These must be replaced when contaminated.

Drying vessels 6 and 0.3 litres

These can be cleaned under running water or in an ultrasonic

bath.

Maintenance

The 3 filters F1 on the rear side of the machine must be

replaced after approx. 100 hrs. The maintenance interval is

shortened depending on the dustiness of the surroundings. This

must be assessed empirically by the operator.

If the filter elements and bags are contaminated too much the

efficiency of the TG200 will be reduced to an unknown extent.

Loading...

Loading...