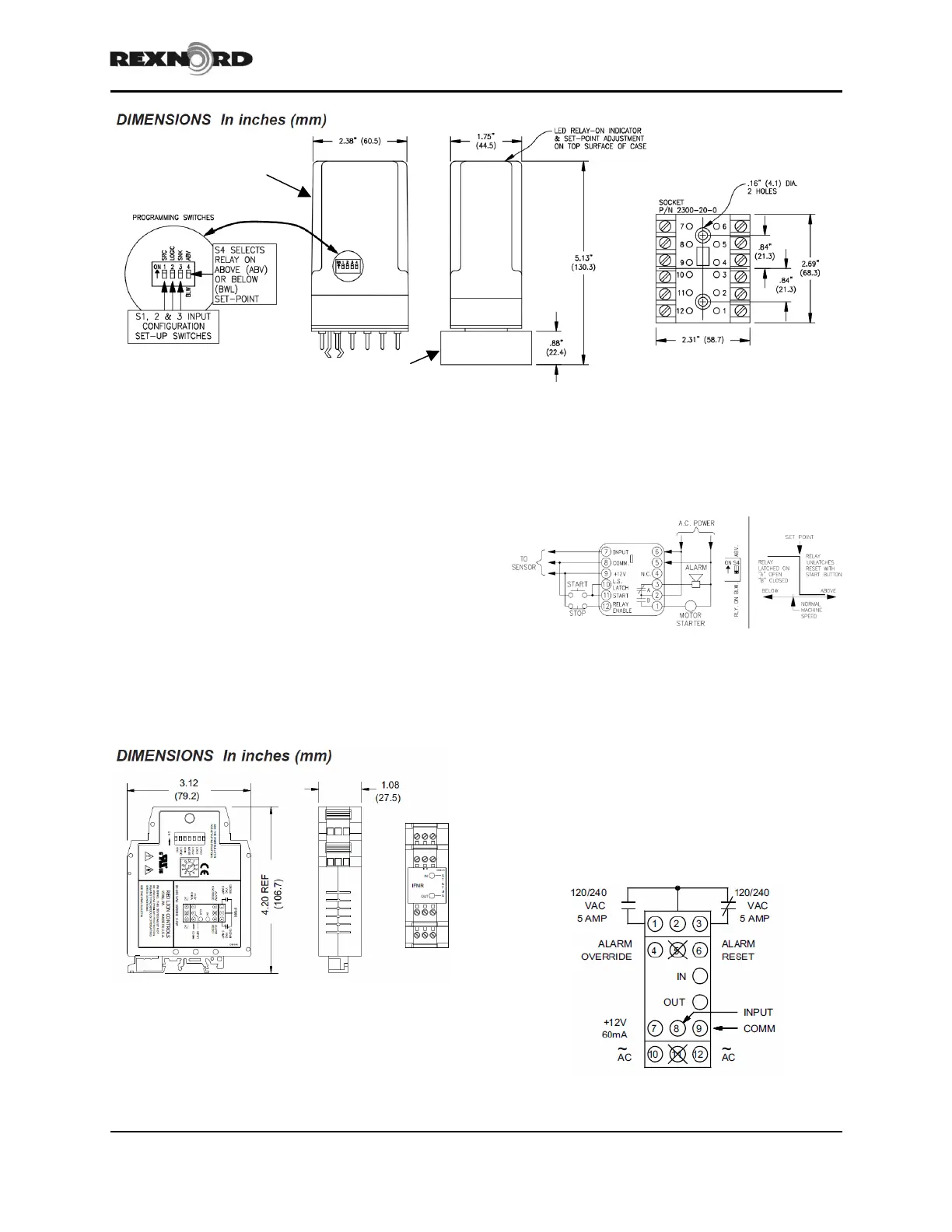

Figure 2 – PRS1 Speed switch mounting dimensions

Rexnord’s over-speed protection system includes the

following components: speed switch (either model

PRS1 or IFMR), magnetic pick-up, and target. The

target is mounted to the clutch hub. A magnetic

pickup is used as the speed sensor and is mounted on

the clutch housing to sense the speed of the target as

it rotates. The speed switch should be mounted in the

motor starter cabinet. Mounting dimensions are

shown in Figure 2 & 3. A 12-pin socket will be

provided with the PRS1 speed switch. The IFMR

switch is equipped with a universal mounting foot for

attachment to standard DIN style mounting rails,

including top hat profile rail according to EN 50 022

– 35x7.5 and 35x15 and G profile rail according to

EN 50 035 – G32.

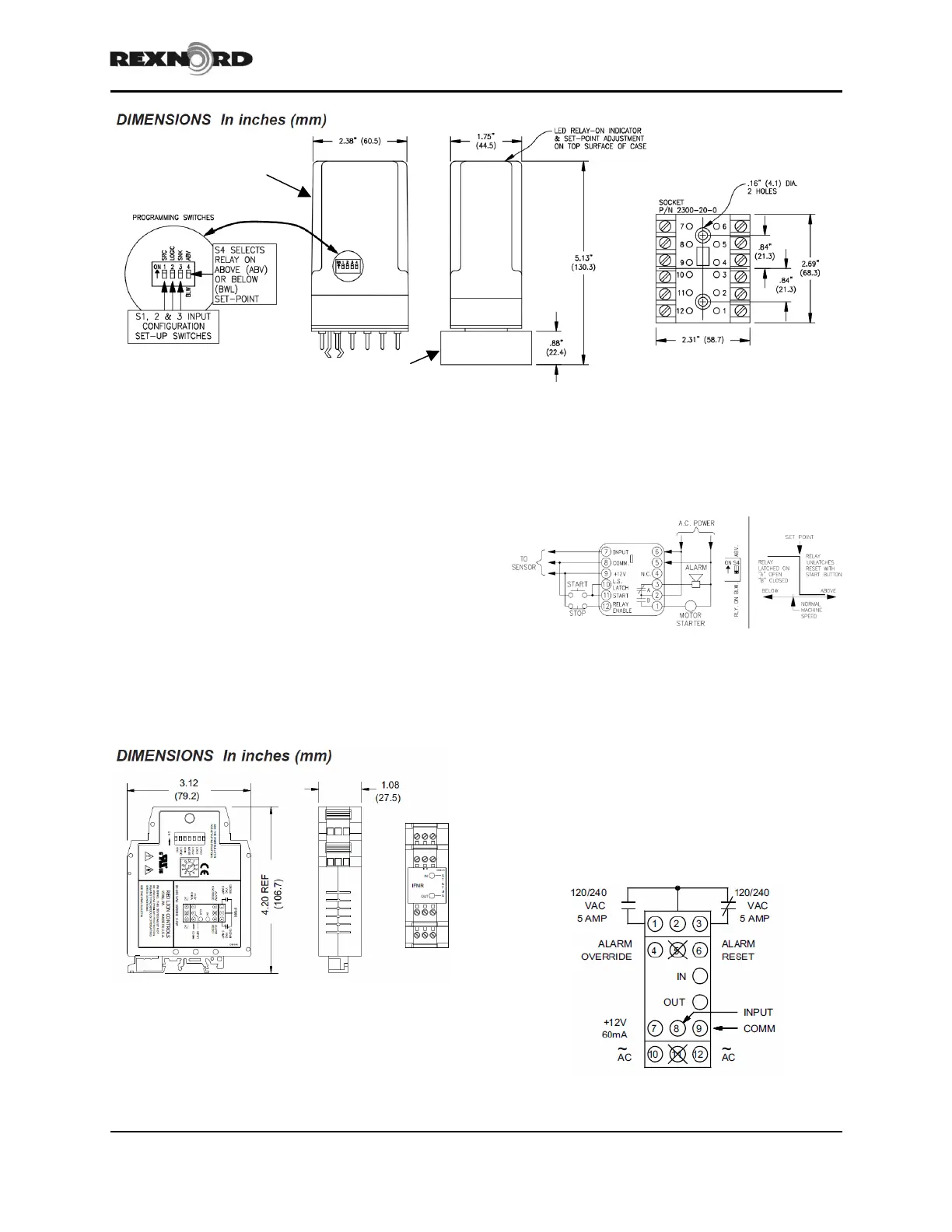

Figure 3 – IFMR Speed Switch

After all components are installed, the speed switch

can be wired per Figure 4 for PRS1 models or Figure

5 for IFMR models.

!

LATCH,!LOW!SPEED!OPERAT E,!OVER SPEED !DRO POU T!

Pushing the start button energizes and latches the relay and starts the

machine. The relay stays latched as long as machine operates below

set-point speed. If the machine exceeds the set-point speed, the relay

unlatches, sounding the alarm and stopping the machine.

Figure 4 – Wiring diagram – PRS1 speed switch

Model IFMR speed switches should have the primary

power connected to terminals 10 and 12 (labeled

AC). For best results, the AC power should be

relatively “clean” and within 85 to 250 VAC, 48 to

62 HZ and 5.5VA. Drawing power from heavily

loaded circuits or from circuits that also power loads

that cycle on and off, should be avoided. Terminals

1, 2 and 3 are used to connect to the relay output.

Terminal 3 is normally closed contact and terminal 2

is the output relay common.

Figure 5 – Wiring diagram – IFMR speed switch

Loading...

Loading...