12

Contact Rexnord Application Engineering if you need assistance.

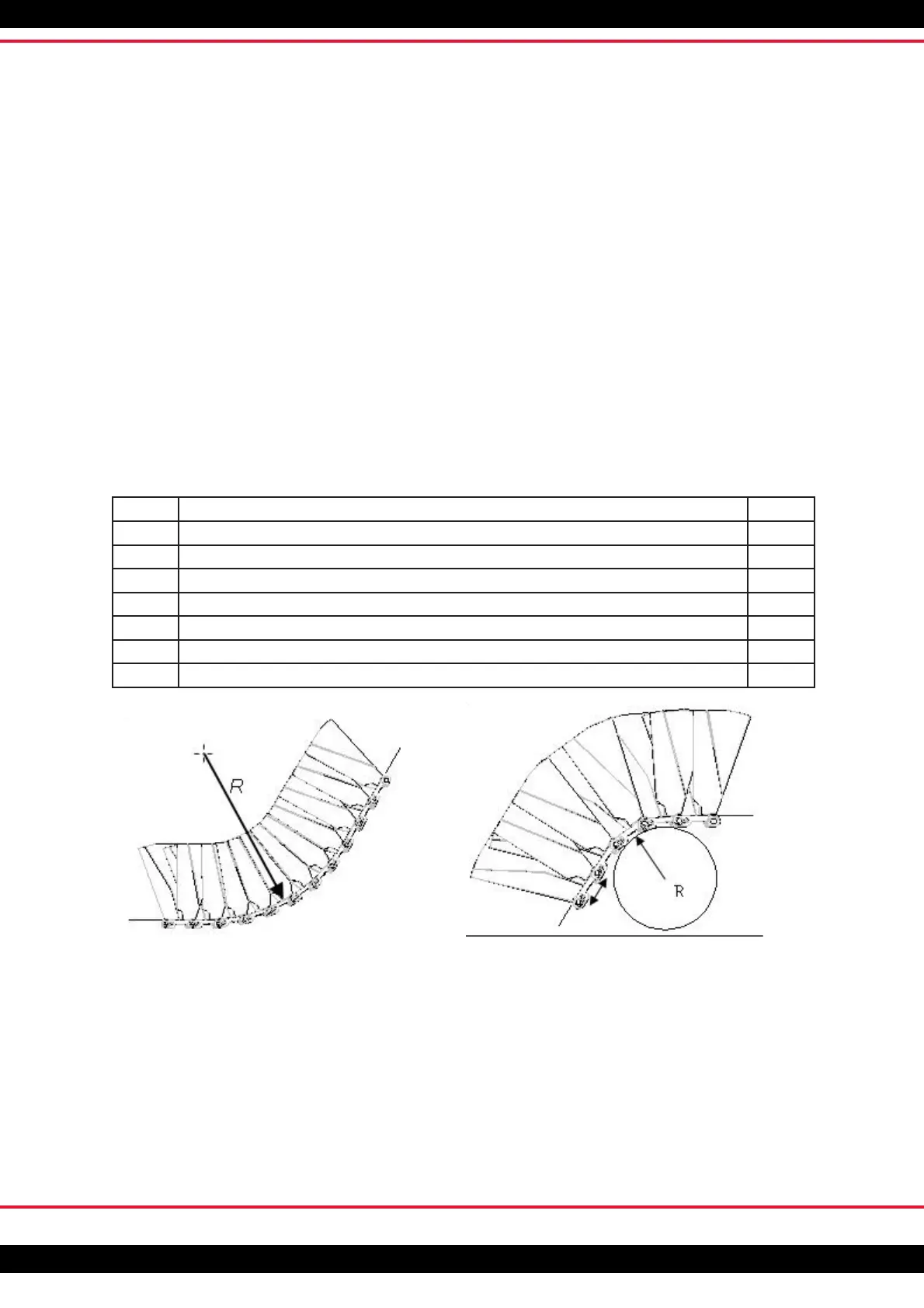

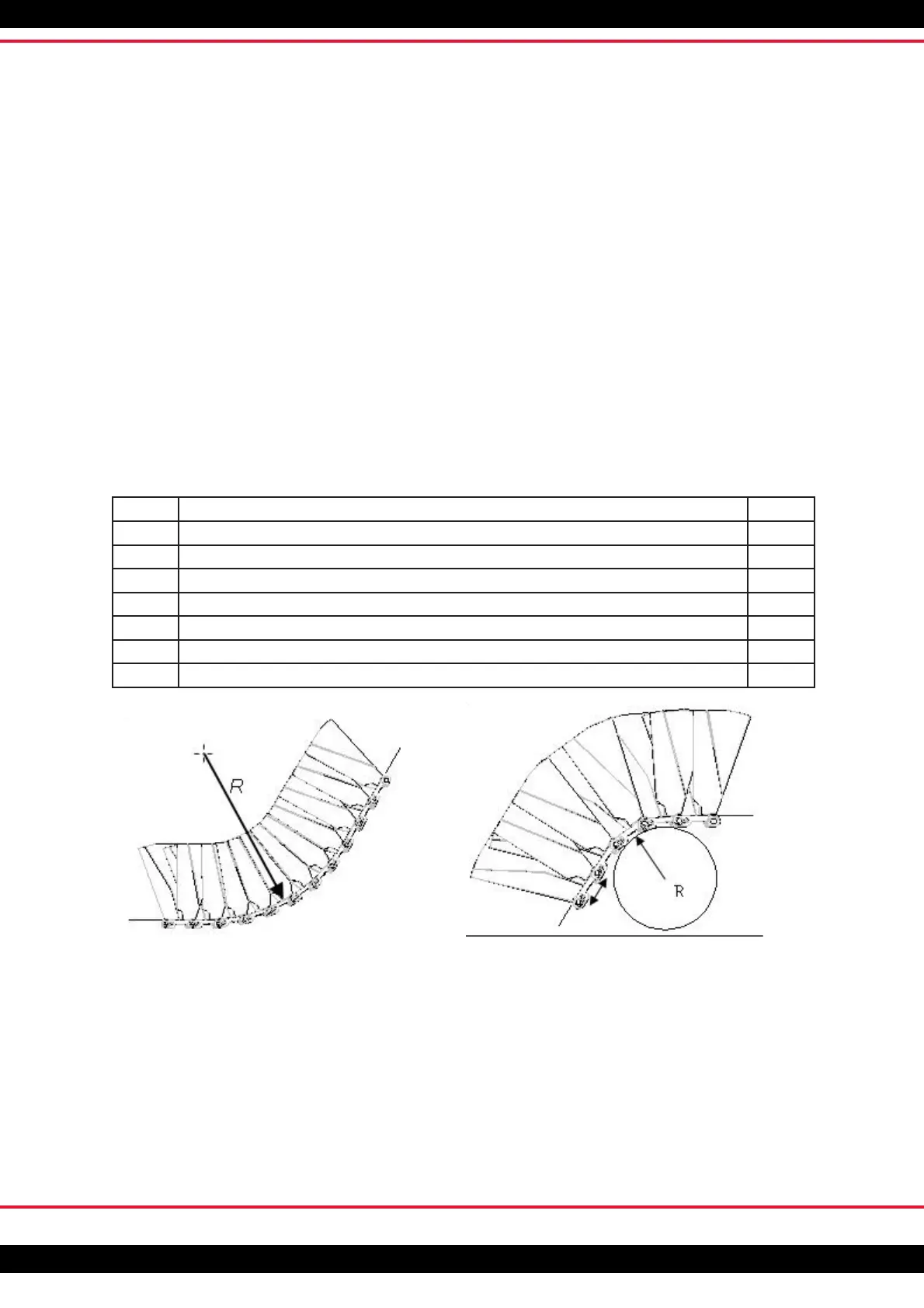

Figure 1. Back-Flex min. 12 inch [305mm] Figure 2. Conveyor Top Radius min. 3½ inch [90mm]

If all answers are YES, the conversion is truly simple. If one of the answers is NO,

some slight conveyor modifi cations are required before Rexnord 2010 ISR can be

installed. If you have some doubt or if one of more items above are answered with

“NO” please contact our application engineers (see contact details in paragraph 1.3).

• At the loading position of the conveyor the positioning of the infeed chute

needs to be reviewed. Due to the slightly different position of 2010 ISR it must

be made sure that product is loaded inside the Integrated SideRail system

and not on top.

Besides the up mentioned recommendations, as with any renewal or conversion of

conveyor Modular belt/chain the carry way and return way should be inspected on

their general condition.

1.5 CHECKLIST

To determine if your conveyor can be changed to Rexnord Integrated SideRail the

following checklist should be completed:

Item Description Yes/No

1Defi ne the current chain specifi cation, is this a 2-inch pitch chain?

2 Is the horizontal – incline backfl ex radius 12 inch [305mm] or larger (see fi g 1)?

3 Is the conveyor top radius 3½ inch [90mm] or large (see FIG 2)?

4 Are the drive sprockets 10 teeth or more?

5 Are the idler sprockets or disks larger than 6 ½ inch [165mm] diameter?

6 Is the current side indent 2 inch [50,8mm] or smaller?

7 Is the smallest chain backfl ex radius in the return part 12 inch [305mm] or larger?

REXNORD ISR CHECKLIST

Loading...

Loading...