Form I-MAPSIII&IV, P/N 222917R9, Page 59

1) Turn the manual gas valve off. On the single-stage gas valve (either regular valve

in FIGURE 41A or dual valve in FIGURE 41B), locate the 1/8” output pressure tap(s).

Connect separate manometers to both 1/8" pipe outlet pressure taps in the valve.

NOTE: A manometer (uid-lled gauge) is recommended rather than a spring type

gauge due to the difculty of maintaining calibration of a spring type gauge.

2) Turn on the manual gas valve. Operate the unit with a call for heat. Check the

outlet pressure with burner at full re.

3) If adjustment is necessary, remove the cap(s) from the adjustment screw(s). Set

pressures to correct setting by turning the regulator screws IN (clockwise) to increase

pressure. Turn regulator screws OUT (counterclockwise) to decrease pressure.

After an adjustment is made, cycle the heat section. Re-check the outlet pressures of

the valve. When checking a dual valve, make sure that the outlet pressure is the

same at both taps.

When outlet pressures are correct for the installation, remove the manometers and

replace the caps. Check for leaks at the pressure tap ttings.

Follow the instructions below to check the valve outlet pressure and make necessary

adjustment. NOTE: Valve outlet pressure is also checked at high re.

Measure the Full Fire

Outlet Pressure of the

Single-Stage Valve(s)

- (can only be done

after heat section is

operating)

Remove the bushing and connect a manometer to each 1/8" pressure tap. NOTE: A

manometer (uid-lled gauge) is recommended rather than a spring type gauge due

to the difculty of maintaining calibration.

2) Turn on the manual gas valve. Operate the unit with a call for heat. With the

burner at full re, check the manifold pressure.

At sea level, the manifold pressure should be 3.5" w.c.

Be certain the actuator has fully opened the ball valve. This can be veried by the

position indicators on top of the actuator (FIGURE 40).

3) In most cases the manifold pressure will be correct and adjustment will not be

required. Replace the ttings and check for leaks.

In the rare instance that adjustment is required, the adjustment is made at the single-

stage gas valve. Continue with the instructions below for adjusting valve outlet

pressure.

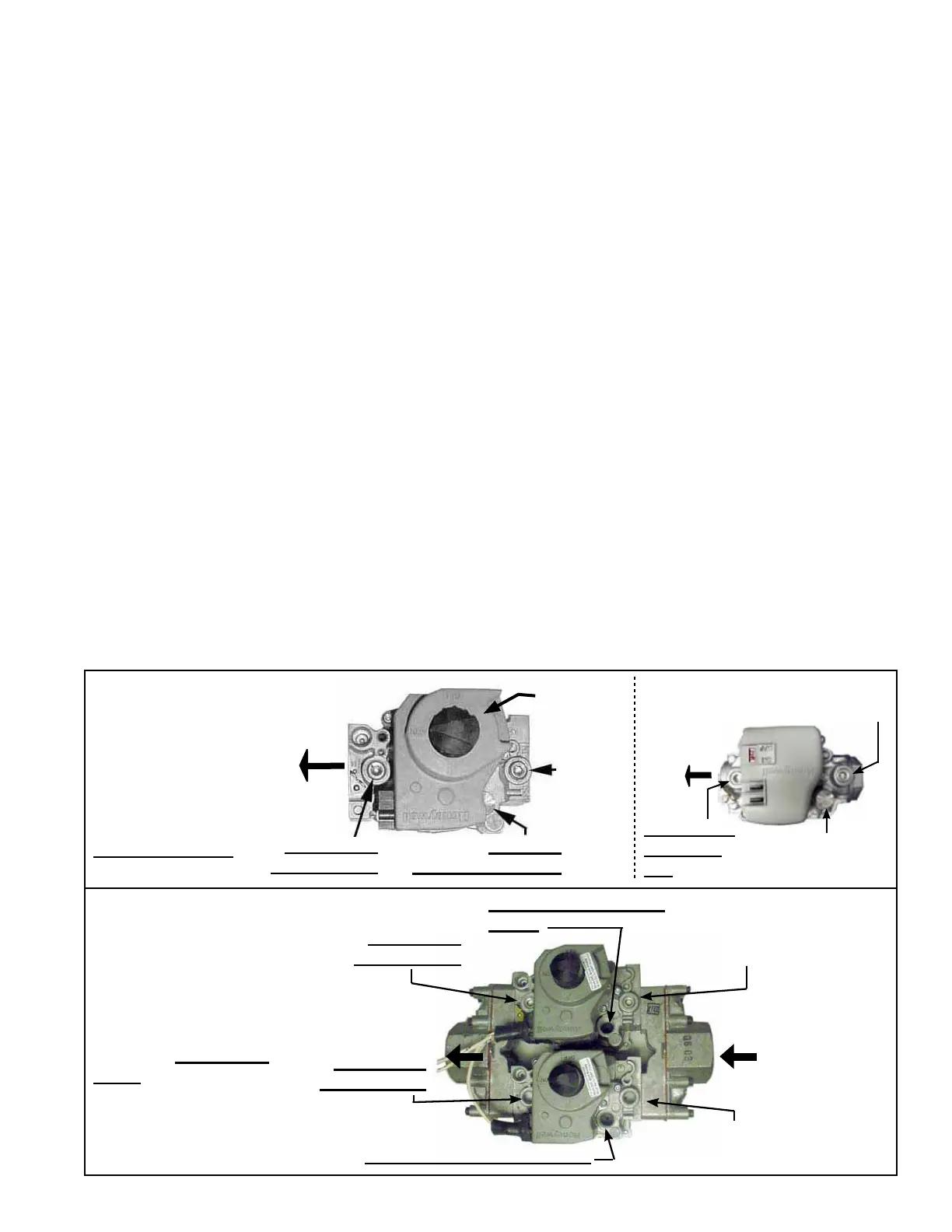

FIGURE 41A -

Outlet Pressure Tap

and Adjustment

Location on Single-

Stage, Valve (two

styles) used on

Heat Sections 100

- 300 in MAPS

®

Cabinets A and B

1/8” Output

Pressure Tap

Inlet

Pressure

Tap

Pressure

Adjustment Screw

Manual

Gas Valve

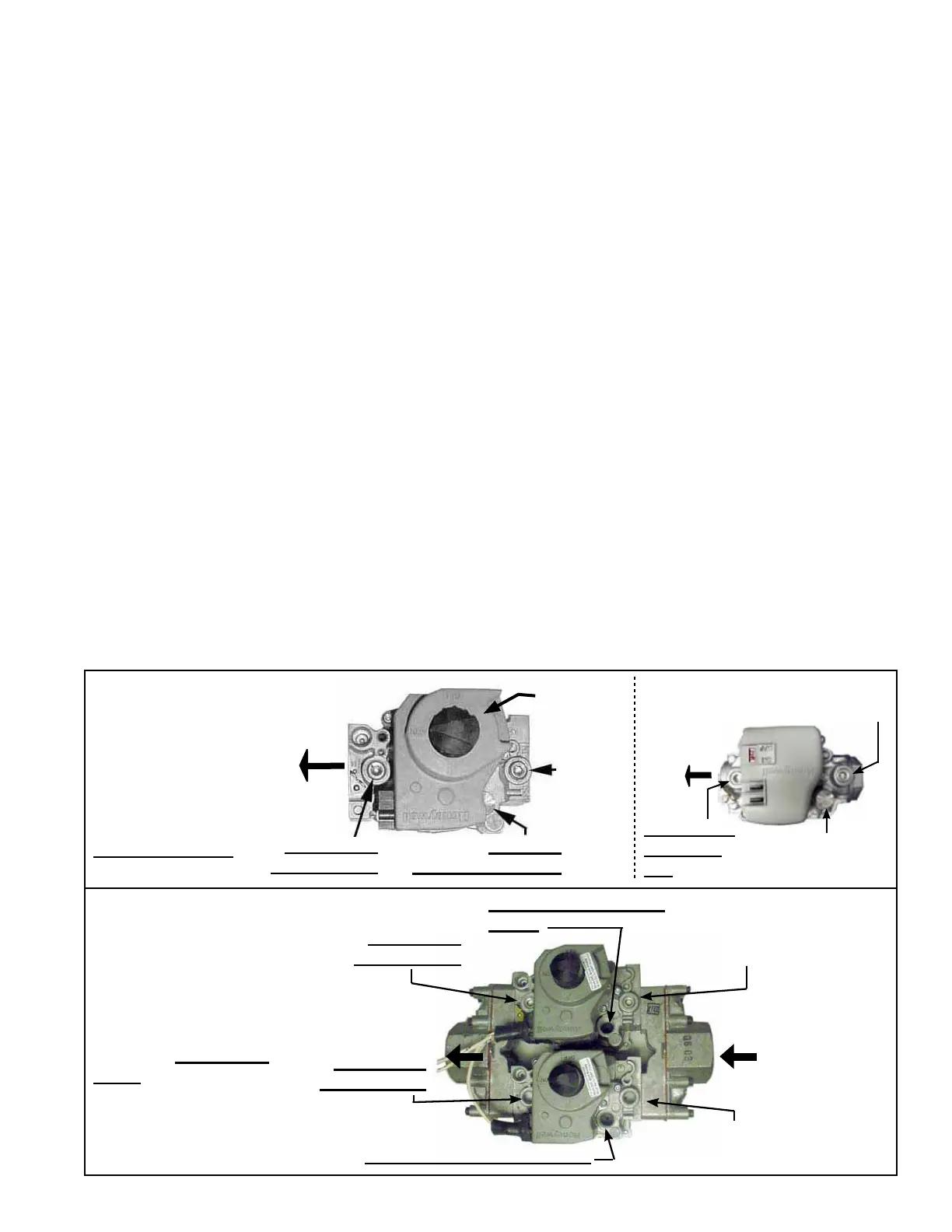

FIGURE 41B - Outlet

Pressure Taps

and Adjustment

Locations on Dual

Single-Stage,

Valve used on Heat

Sections 400 - 1600

in MAPS

®

Cabinets C

and D

1/8” Output

Pressure Tap

Inlet Pressure

Tap

Inlet Pressure

Tap

1/8” Output

Pressure Tap

Pressure Adjustment

Screw

Minimum inlet

pressure is

6" w.c.

Pressure Adjustment Screw

1/8” Outlet

Pressure

Tap

Inlet Pressure

Tap

Adjust Outlet

Pressure

Loading...

Loading...