73

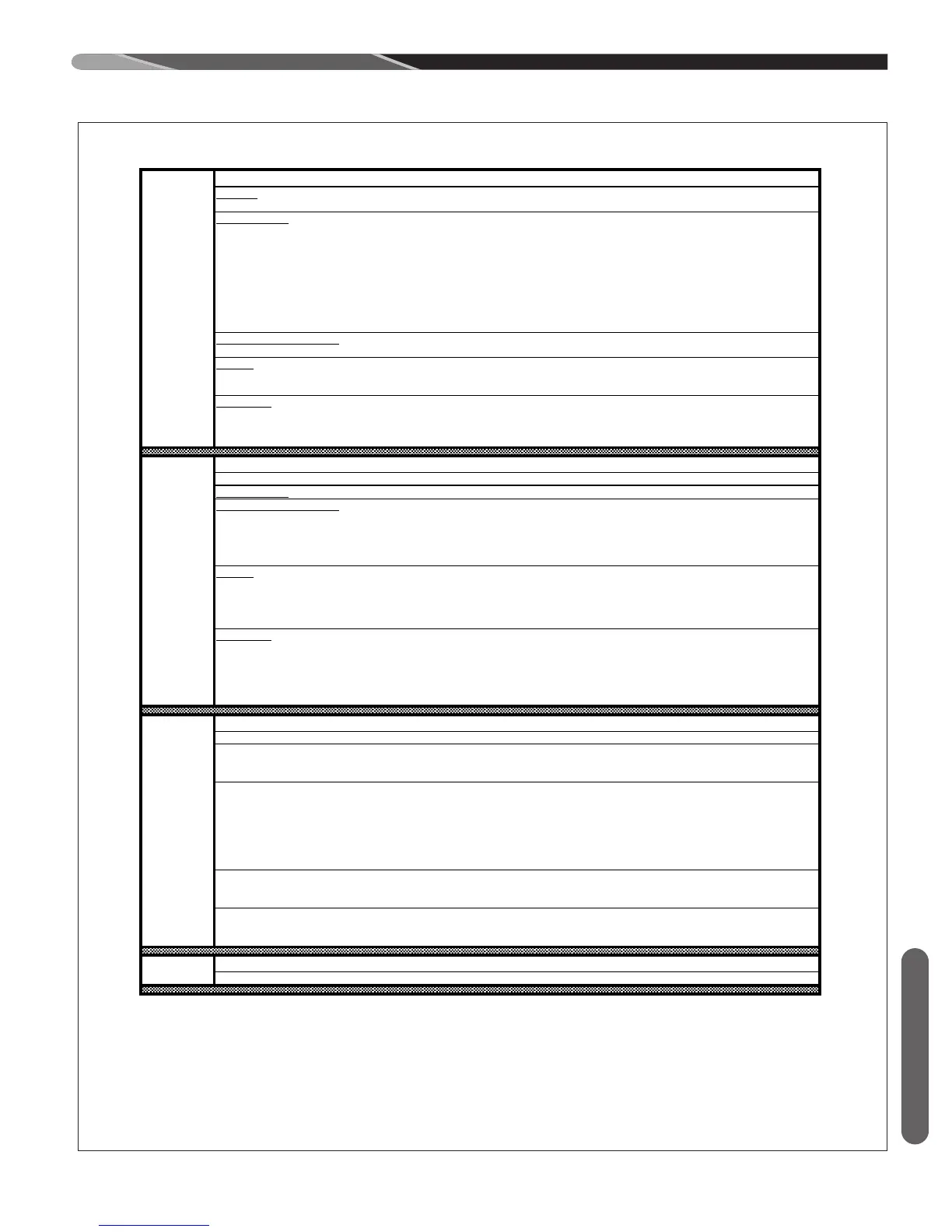

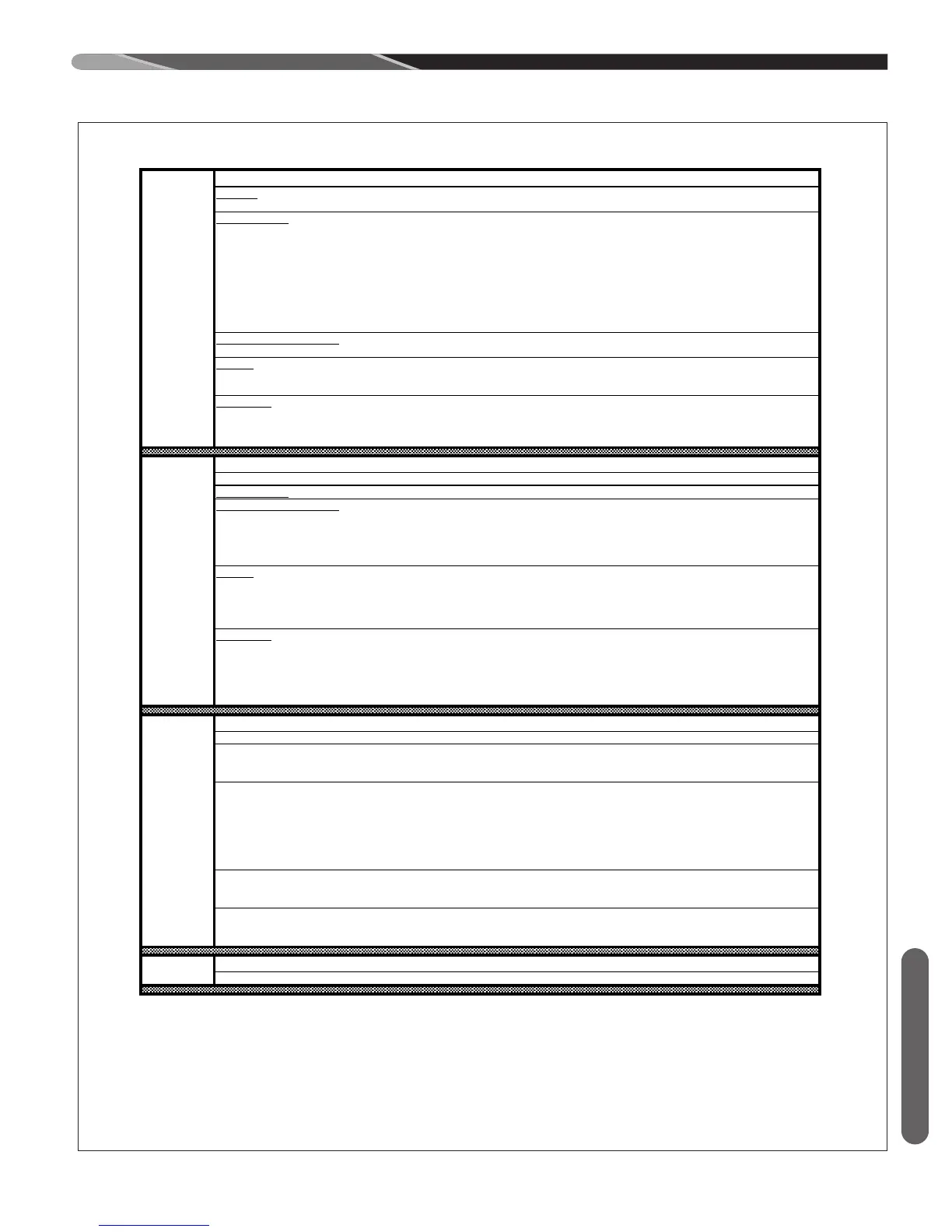

TABLE 13 (continued)

802V FAULT CODES WITH DESCRIPTIONS AND SOLUTIONS

DESCRIPTION: The furnace control (I.F.C.) can not communicate with the blower motor.

SOLUTION

:

(1) Check wiring, connectors and terminals - repair or replace as necessary.

(4) The motor has failed catastrophically.

93

INTERNAL CONTROL FAULT DETECTED

STATUS: This is a critical fault. The furnace will not operate in any mode of operation.

DESCRIPTION: This is a severe fault that should rarely (if ever) be discovered in the field. It

is an indicator of an internal

microprocessor fault on the furnace control (or I.F.C.) or voltage applied to the main gas valve solenoid when there should be

none.

(1) Check for miswiring in the furnace.

(2) Replace the furnace control (or I.F.C.).

SOLUTION:

66

BLOWER CUTBACK

STATUS: This is a non-critical fault experienced by the furnace. All operations (including thermostat calls) should continue as

normal with no perceivable difference in operation.

DESCRIPTION

: The blower motor is operating at the highest rpm or torque that specifications allow but the application requires

more torque or speed in order to get the desired airflow under the current static pressure condit

ions. The motor will continue to

operate because internal software will prevent operation above the permitted range. However, a fault is sent to the furnace

control (or I.F.C.) from the motor. Note: Th is fault will

not be displayed after

the first three minutes of blower operation after power reset. Further, this fault will not be logged in the

fault buffer or fault history after the first hour of operation and will only be logged into the faul

t buffer a maximum of one time.

This code (66) indication is intended as a tool to notify the installer of inadequate airflow due to excessive static pressure in the

duct of the system. The code is not intended to

be a fault code. It is merely an operating indicator.

CAUSE

:

(2) Furnace control software test failure - failed furnace control (or I.F.C.).

(1) The blower has hit the maximum speed or torque limit specified by the manufacturer because the static pressure is too high.

SOLUTION

:

68

(2) There is no line voltage to the motor.

(3) The furnace model data is faulty or corrupted.

99

REMOTE FAULTS RESET PERFORMED

This is a notification that fault codes in the fault buffer have been reset.

NO BLOWER COMMUNICATIONS

STATUS: This is a critical fault. The furnace will not operate in any mode.

(1) 24VAC or similar voltage applied to the main gas valve solenoid circuit unexpectedly.

CAUSE:

EXPECTED OPE

RATION: If possible, if the furnace was in heating operation when this fault occurred, the gas valve will

immediately close (flame will be lost), IBM (Indoor Blower Motor) operation will immediately stop and

the furnace will shut down

normally (except without IBM operation) with IDM (Induced Draft Motor) post-purge at the correct speed. After the post purge (o

immediately if no heat call was present), no other operation (including thermostat calls) will occur until this fault is cleared.

However, this fault may also indicate an internal microprocessor failure. This may

mean that the heat call will not end as

expected and that all outputs will be de-energized and gas valve closed immediately when the fault is sensed.

(2) Check line voltage wiring, connectors and terminals to the Power Factor Correction choke and ECM motor. Repair and

replace as necessary.

(3) Replace the furnace memory card with the correct replacement part from ProStock.

(4) Replace the motor.

(1) The static pressure is too high because the ductwork is improperly

designed or is restricted for some other reason or the

filter needs cleaning or replacing. Remove the obstruction or repair the duct so that static pressure does not exceed published

values in the specification sheets or

installation instructions for the furnace.

CAUSE

:

(1) The wires between the blower motor have been disconnected or there is a poor connection.

EXPECTED OPERATION

: All (including thermostat) operation should continue as normal. Blower operation may be slightly

compromised but will continue.

EXPECTED OPERATION

: If the furnace was in heating operation when this fault occurred, the gas valve will immediately close

(flame will be lost), IBM (Indoor Blower Motor) operation will immediately stop and the furnace will shut down norma

lly (except

without IBM operation) with IDM (Induced Draft Motor) post-purge at the correct speed. After the post purge (or immediately if

no heat call was present), no other operation (including thermostat calls) will occur until this

fault is cleared.

Loading...

Loading...