9

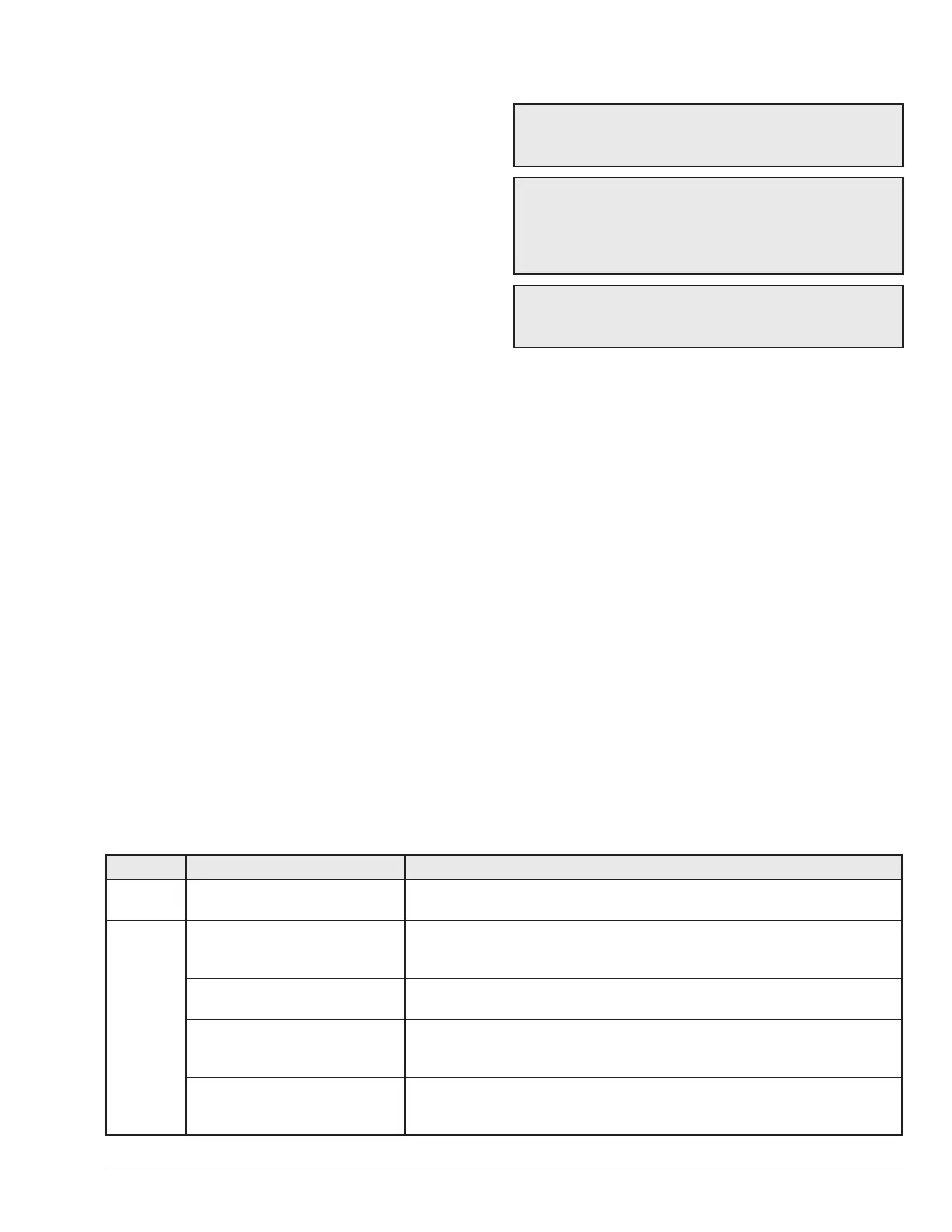

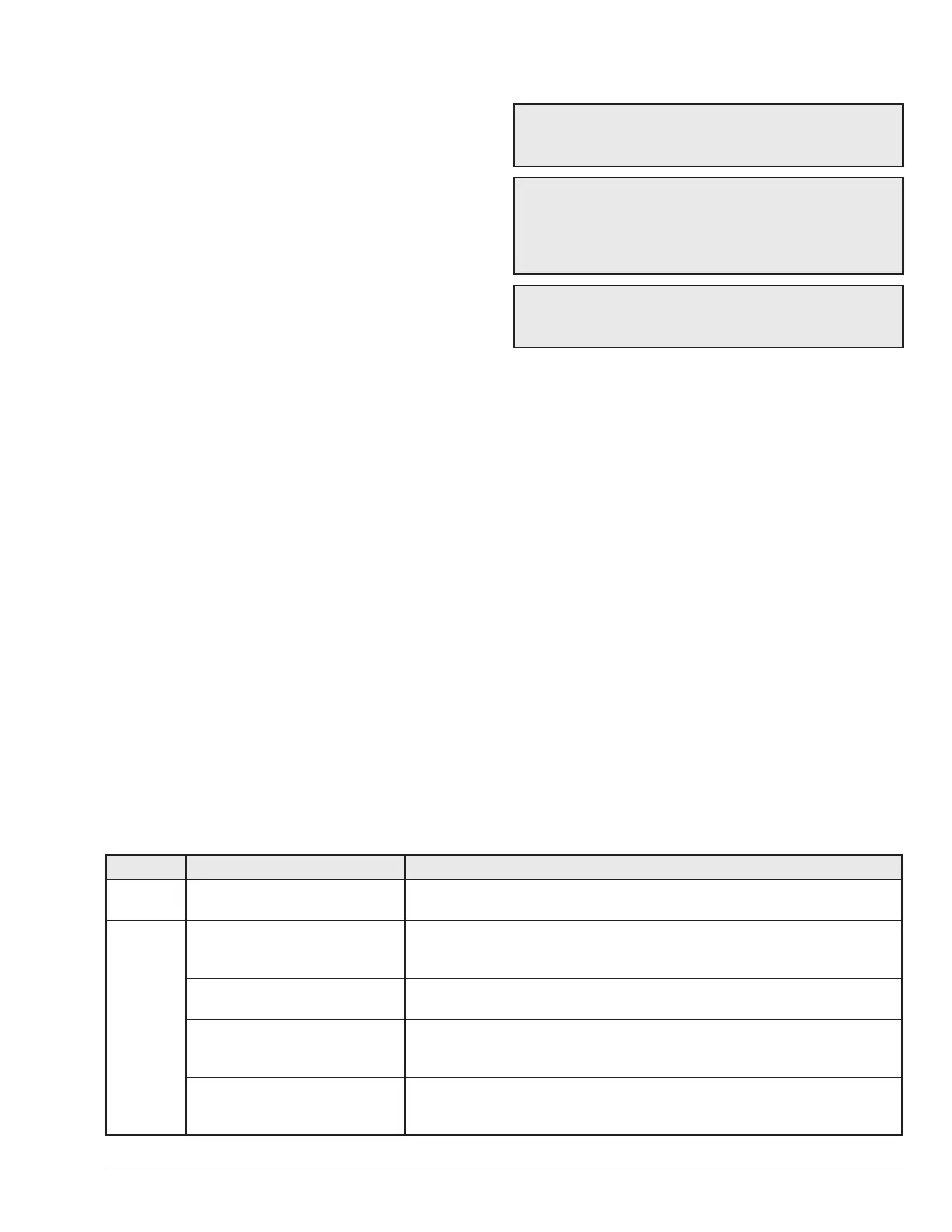

Period Check Point Related Problems

Weekly Check pressure gauge

If pressure increases by 8-10 PSI, then backwash and rinse the lter as per

instructions

Quarterly

Check all gaskets and pressure

gauge.

Isolate and turn o the pump. Remove all gaskets and turn over. You can also

apply a silicone-based grease to extend gasket life. If dry, then contact your

local pool professional for replacement

Check around the unit for leaves,

debris or signs of ooding.

Replace any debris that is restricting air circulation around the lter. If in a

ood prone location, rectify

Check for any insects, ants, etc.

It is a good practice to use a good quality surface spray around your

equipment. Make sure all units are turned o and then spray around all units

to eliminate any insects, ants, etc

Check for any leaks

If you notice any water leaking from the lter or other equipment, check the

gaskets rst and reseal. If leaks continue, contact your local pool professional

to assess and rectify

Table B. Maintenance Service Schedule

3. Power up the pump again. The water flow is

automatically reversed through the filter so the water

is directed from the bottom of the tank, then up

through the sand. This flushes the trapped dirt and

debris out of the waste line.

4. Check through the visual sight glass on the multi-

function valve outlet. The duration of the backwash

operation will depend on how dirty your filter is.

Continuously check the sight glass until the water

becomes clear, after which the pump is turned off.

5. Change the position of the multiport valve handle

from BACKWASH to RINSE.

6. Turn the pump back on. The water flow will now be

directed through the sand bed and then out through

the waste line. This will settle the sand bed properly

for normal operation.

7. Continue checking the sight glass until the water

is clear which usually is about half the time of the

backwash cycle.

8. Turn the pump off.

9. Change the position of the multiport valve handle

from RINSE to FILTER.

10. Turn the pump on.

Chemical Cleaning

Algae load, calcication, sanitation and other poor water

conditions will aect the proper function and eciency

of the lter. Follow local guidelines and pool professional

advice to optimize these other key facets of water quality

that the lter does not control, but is impacted by.

Winterizing the System

AA

CAUTION: Allowing water to freeze in the system will

damage the system and cause potential water damage/

ooding and potential property damage.

AA

CAUTION: The Multiport Valve should be left in the

"Winterize" position during the shutdown season so

the rubber seal of the valve diverter has no pressure on

it. Failure to do so can damage the valve diverter seal

which can cause property damage from leaking water.

CAUTION: Only use Propylene Glycol as an anti-freeze,

as other anti-freeze solutions are highly toxic and will

damage the pump.

Winterizing is a process for protecting your sand lter

during freezing conditions that can damage all pool

ltration equipment. Damage results from ice expansion

(ice takes up more volume than liquid water) cracking the

parts. It is highly recommended to take the following steps

when preparing your lter for winter conditions:

1. Backwash the filter for at least 30 minutes before

closing down the pool for winter. This will clean the

filter bed thoroughly and remove any debris from the

system.

2. Drain the filter tank by removing the drain cap at the

bottom of the filter tank. Also leave the cap off during

winter.

3. Set the control valve handle between the RINSE and

FILTER. This will lift the handle and help with the

draining process by allowing air to enter into the tank.

4. Unscrew the pressure gauge from the control valve

and store the pressure gauge indoors.

5. Drain and winterize the pump according to the pump

instructions.

This is an ideal time for any repairs that may be required

during the o-season. Most pool professionals have

recommendations of what will be needed before the next

pool season.

CONTROLLED COPY approved for factory use on 4/16/2020. RAYPAK PROPRIETARY AND CONFIDENTIAL INFORMATION . Approval signatures on file in Engineering.

Loading...

Loading...