16

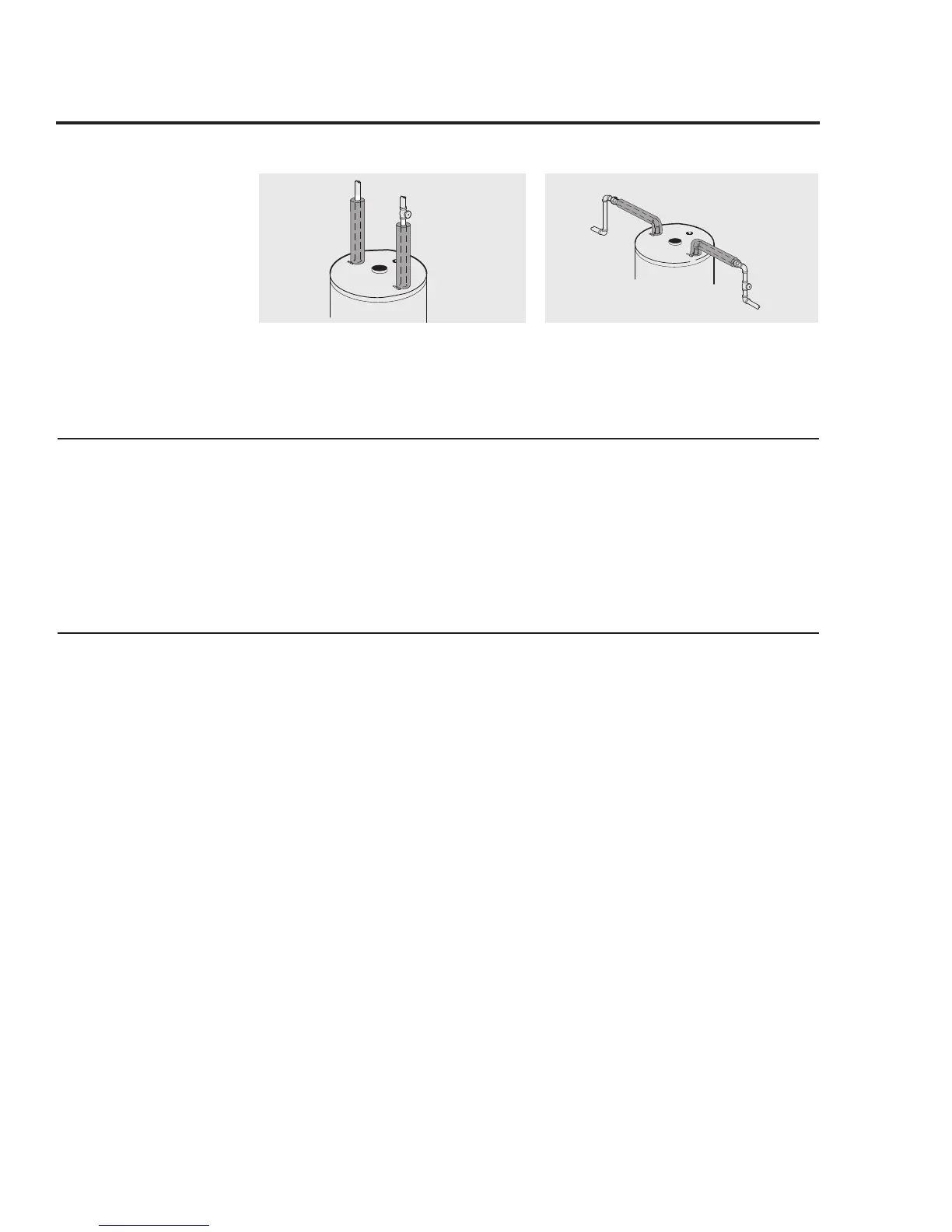

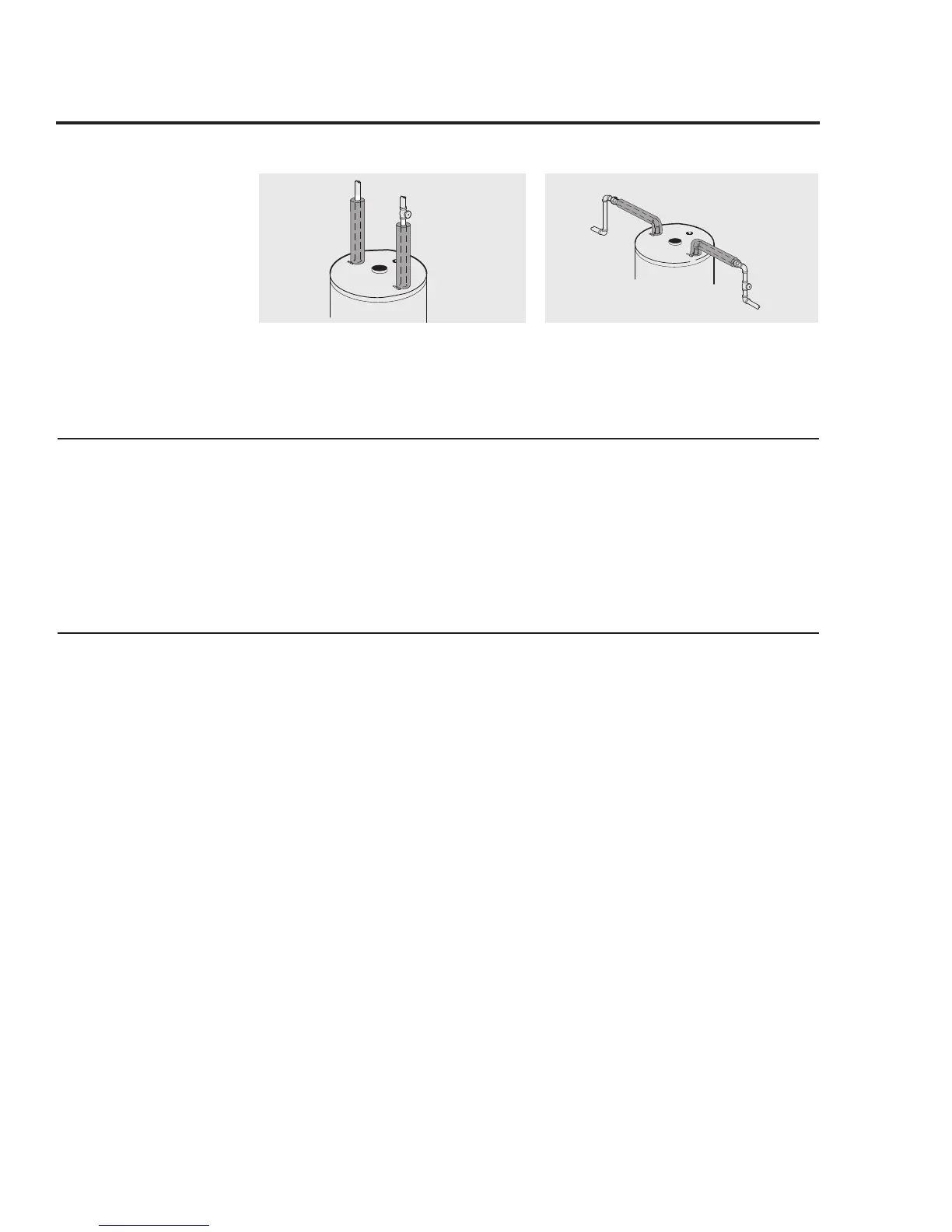

For increased energy efficiency, some

water heaters have been supplied with

two 24” (60.9 cm) sections of pipe

insulation. Please install the insulation,

according to the illustrations above, that

best meets your requirements.

DO

❑ DO check inlet gas pressure to ensure

that it is within the range specified on the

rating plate.

❑ DO provide adequate air for combustion

and ventilation as discussed in the Use and

Care Manual and the National Fuel Gas

Code.

❑ DO maintain proper clearances to

combustibles as specified on the instruction/

warning label.

❑ DO ensure that the venting system

complies with the guidelines found in the

Use and Care Manual and National Fuel Gas

Code.

❑ DO contact a qualified service technician

if the pilot or main burner will not stay lit.

DON’T

❑ DON’T block or restrict the vent

terminal.

❑ DON’T remove the Burner Access

Door unless absolutely necessary. This

should only be done by a qualified service

technician. A new burner access door gasket

must be installed on any burner access door

that has been removed.

❑ DON’T install this water heater where

standing water may occur. The base of the

water heater is meant to be mounted on a dry

surface.

❑ DON’T operate the water heater if the

sight glass or burner access door grommet is

damaged or broken.

Typical vertical piping arrangement

Typical horizontal piping arrangement

During Installation of this water heater...........

Heat Trap

Hot and Cold Pipe Insulation Installation

For increased energy efficiency, some

water heaters have been supplied with

factory installed 3/4” NPT heat traps in

the hot outlet line and cold water inlet

line.

NOTICE: Do not apply heat to the

HOT or COLD water connections. If

sweat connections are used, sweat

tubing to adapter before fitting adapter

to the water connections on heater. Any

heat applied to the water supply fittings

will permanently damage the dip tube,

nipples, and/or heat traps.

Installing the water heater.

Loading...

Loading...