23

DIRECT VENT

INSTALLATIONS

READ AND FOLLOW ALL

INSTRUCTIONS IN THIS SECTION.

FAILURE TO PROPERLY VENT

THIS FURNACE CAN CAUSE

CARBON MONOXIDE POISONING

OR AN EXPLOSION OR FIRE,

RESULTING IN PROPERTY

DAMAGE, PERSONAL INJURY

OR DEATH.

Direct vent installations require a

dedicated combustion air and venting

system. All air for combustion is taken

from the outside atmosphere and all

combustion products are discharged to

the outdoors. Therefore, no

ventilation or combustion air

openings are required.

IMPORTANT: The plastic combustion

air and venting components are of

Schedule 40 PVC. If using ABS piping

ensure that the solvent cement is

compatible for joining PVC to ABS

components or use a mechanical

connection that can withstand the vent

temperatures and are corrosion

resistant.

INSTALLATION GUIDELINES

All exhaust piping must be installed in

compliance with Part 7, “Venting of

Equipment,” of the latest edition of the

National Fuel Gas Code NPFA54/

ANSI Z223.1-, local codes or

ordinances and these instructions.

1. Vertical piping is preferred.

2. All horizontal piping must slope

upward a minimum of

1

/4 inch

per foot of run so that condensate

drains toward the furnace.

3. All horizontal runs must be

supported at least every 4 feet.

No sags or dips are permitted.

4. IMPORTANT: Do not common

vent with any other appliance. Do

not install in the same chase or

chimney with a metal or high

temperature plastic pipe from

another gas or fuel-burning

appliance unless the required

minimum clearances to

combustibles are maintained

between the PVC pipe and other

pipes. Minimum 3 ft. clearance

required between combustion air

inlet and any other exhaust.

5. For horizontal runs where water

may collect, wrap the vent pipe

with self-regulating 3 or 5 watt

heat tape. The heat tape must be

U.L. listed and installed per the

manufacturer’s instructions.

6. The minimum, pipe length is

5 feet for combustion air and

exhaust.

7. Do not install elbows back to

back. Allow at least 15” between

elbows.

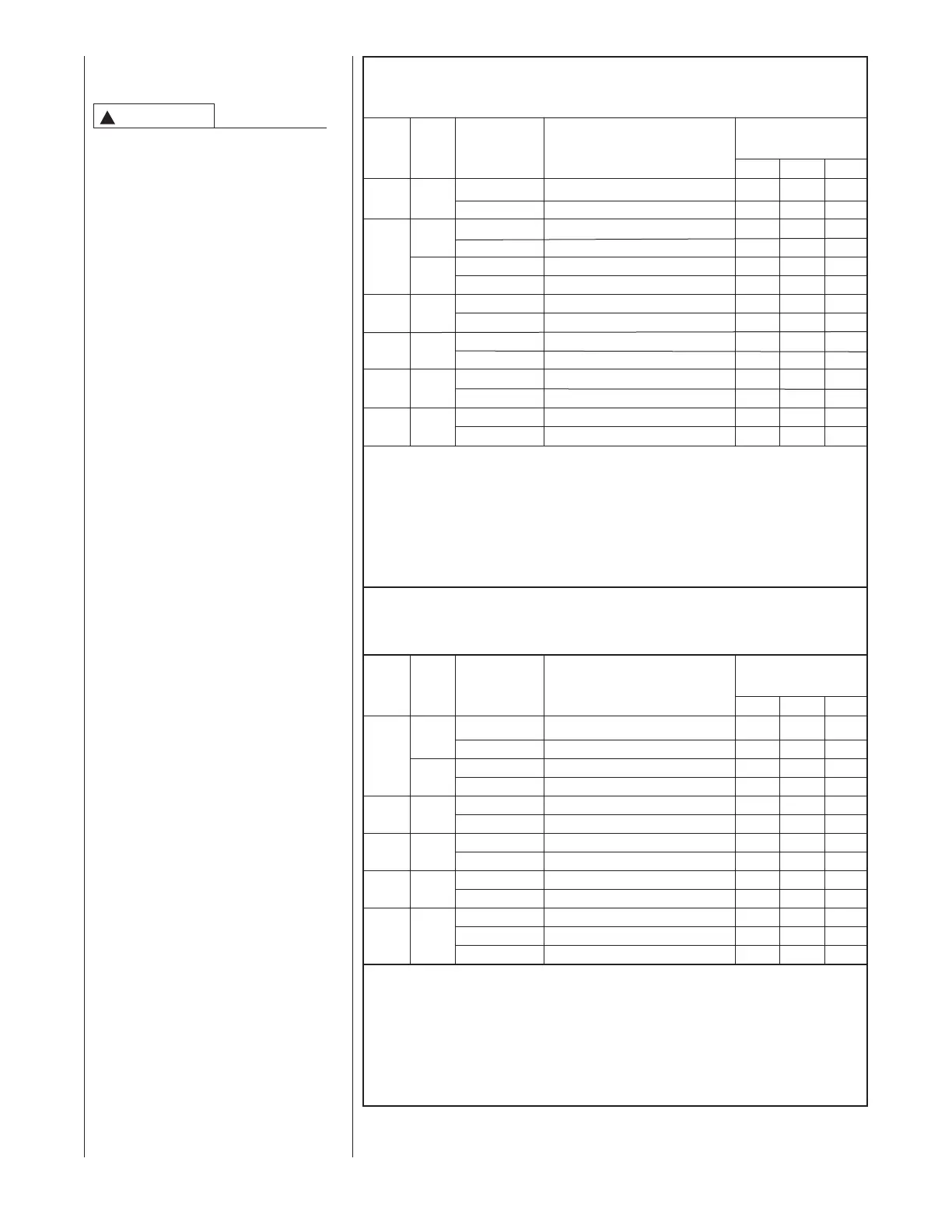

Size the exhaust and combustion air

intake pipes as specified in Table 4 or

Table 5. This table lists the maximum

!

WARNING

Standard/Concentric RXGY-D02/RXGY-D02A/RXGY-E03A/GXGY-G02 65 60 55

45,000 2”

Alternate RXGY-D02/RXGY-D02A 55 50 45

Standard/Concentric RXGY-D02/RXGY-D02A/RXGY-E03A/RXGY-G02 40 35 30

2”

Alternate RXGY-D02/RXGY-D02A 40 35 30

60,000

3”

Standard/Concentric RXGY-D03/RXGY-D03A/RXGY-E03A/RXGY-G02 120 120 120

Alternate RXGY-D03/RXGY-D03A 110 105 100

Standard/Concentric RXGY-D03/RXGY-D03A/RXGY-E03A/RXGY-G02 50 40 NA

75,000 3”

Alternate RXGY-D03/RXGY-D03A 50 40 NA

Standard/Concentric RXGY-D03/RXGY-D03A/RXGY-E03A/RXGY-G02 110 105 95

90,000 3”

Alternate RXGY-D03/RXGY-D03A 50 40 35

Standard/Concentric RXGY-D03/RXGY-D03A/RXGY-E03A/RXGY-G02 50 40 NA

105,000 3”

Alternate RXGY-D03/RXGY-D03A 50 40 NA

Standard/Concentric RXGY-D03/RXGY-D03A/RXGY-E03A/RXGY-G02 50 40 30

120,000 3”

Alternate RXGY-D04/RXGY-D04A 45 35 30

FURNACE

INPUT

PIPE

SIZE

TERMINATION

VENT TERMINATION

KIT RECOMMENDED

2 46

NUMBER OF ELBOWS

45 or 90 Degrees

Medium / Long Radius ONLY

TABLE 4

UPFLOW UNITS FOR DIRECT VENT APPLICATIONS - AIR FOR COMBUSTION

PROVIDED FROM OUTDOORS

MAXIMUM ALLOWABLE LENGTH IN FEET OF EACH EXHAUST PIPE AND INTAKE AIR PIPE

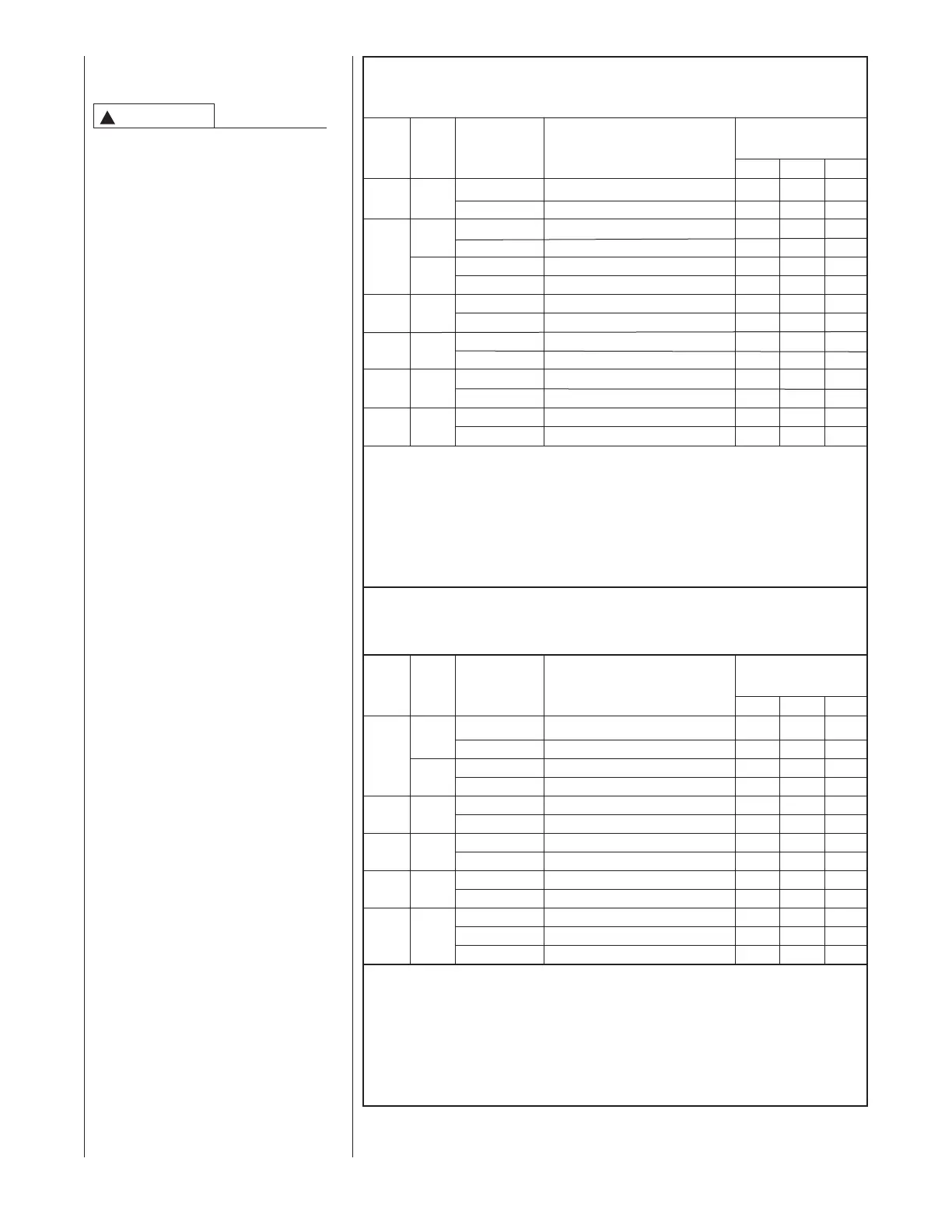

TABLE 5

DOWNFLOW/HORIZONTAL UNITS FOR DIRECT VENT APPLICATIONS - AIR FOR COMBUSTION

PROVIDED FROM OUTDOORS

MAXIMUM ALLOWABLE LENGTH IN FEET OF EACH EXHAUST PIPE AND INTAKE AIR PIPE

FURNACE

INPUT

PIPE

SIZE

TERMINATION

VENT TERMINATION

KIT RECOMMENDED

1 - 2 3 - 4 5 - 6

NUMBER OF ELBOWS

22.5, 45 or 90 Degrees

Medium / Long Radius ONLY

NOTES:

1. N.A. - NOT APPLICABLE

2. MAXIMUM OF 6 ELBOWS MAY BE USED. DO NOT COUNT ELBOWS IN ALTERNATE TERMINATION KIT.

MEDIUM OR LONG SWEEP ELBOWS MAY BE USED.

3. A 45 DEGREE ELBOW IS CONSIDERED ONE ELBOW.

4. CONCENTRIC TERMINATION NO. RXGY-E03/RXGY-E03A IS FOR THRU-THE-ROOF OR THRU-THE-WALL VENTING.

5. USE KITS RXGY-DO2/D02A (2"), RXGY-G02 (2"), OR RXGY-D03/D03A (3") FOR STANDARD OR ALTERNATE

THRU-THE-WALL VENTING.

6. USE KITS RXGY-D04/D04A FOR ALTERNATE VENTING OF 120,000 BTUH UNITS WITH LONG RUNS.

7. KIT NUMBERS CONTAINING SUFFIX “A” ARE APPROVED FOR INSTALLATION IN CANADA.

8. NO SCREENS MAY BE USED TO COVER COMBUSTION AIR AND EXHAUST.

(A*) = 17

1

⁄2” CABINET (B*) = 21” CABINET

2”

Standard/Concentric RXGY-D02/RXGY-D02A/RXGY-E03A/RXGY-G02 40 35 30

Alternate RXGY-D02/RXGY-D02A 30 25 20

60,000

3”

Standard/Concentric RXGY-D03/RXGY-D03A/RXGY-E03A/RXGY-G02 120 120 120

Alternate RXGY-D03/RXGY-D03A 110 105 100

Standard/Concentric RXGY-D03/RXGY-D03A/RXGY-E03A/RXGY-G02 120 120 120

75,000 3”

Alternate RXGY-D03/RXGY-D03A 100 95 85

Standard/Concentric RXGY-D03/RXGY-D03A/RXGY-D03A/RXGY-G02 110 105 95

90,000 3”

Alternate RXGY-D03/RXGH-D03A 50 40 35

Standard/Concentric RXGY-D03/RXGY-D03A/RXGH-E03A/RXGY-G02 65 60 55

105,000 3”

Alternate RXGY-D03/RXGY-D03A 50 40 35

Standard/Concentric RXGY-D03/RXGY-D03A/RXGY-E03A/RXGY-G02 40 35 30

120,000 3” Alternate RXGY-D03/RXGY-D03A 40 35 30

Alternate RXGY-D04/RXGY-D04A 45 35 30

NOTES:

1. N.A. - NOT APPLICABLE

2. MAXIMUM OF 6 ELBOWS MAY BE USED. DO NOT COUNT ELBOWS IN ALTERNATE TERMINATION KIT.

MEDIUM OR LONG SWEEP ELBOWS MAY BE USED.

3. A 45 DEGREE ELBOW IS CONSIDERED ONE ELBOW.

4. CONCENTRIC TERMINATION NO. RXGY-E03/RXGY-E03A IS FOR THRU-THE-ROOF OR THRU-THE-WALL VENTING.

5. USE KITS RXGY-DO2/D02A (2"), RXGY-G02 (2"), OR RXGY-D03/D03A (3") FOR STANDARD OR ALTERNATE

THRU-THE-WALL VENTING.

6. USE KITS RXGY-D04/D04A FOR ALTERNATE VENTING OF 120,000 BTUH UNITS WITH LONG RUNS.

7. KIT NUMBERS CONTAINING SUFFIX “A” ARE APPROVED FOR INSTALLATION IN CANADA.

8. NO SCREENS MAY BE USED TO COVER COMBUSTION AIR AND EXHAUST.

(A*) = 17

1

⁄2” CABINET (B*) = 21” CABINET

Loading...

Loading...