RHEONIK Messgeräte GmbH REV. I, Apr. 2004

.

Operation Manual RHE 07, 08, 11

Page

7

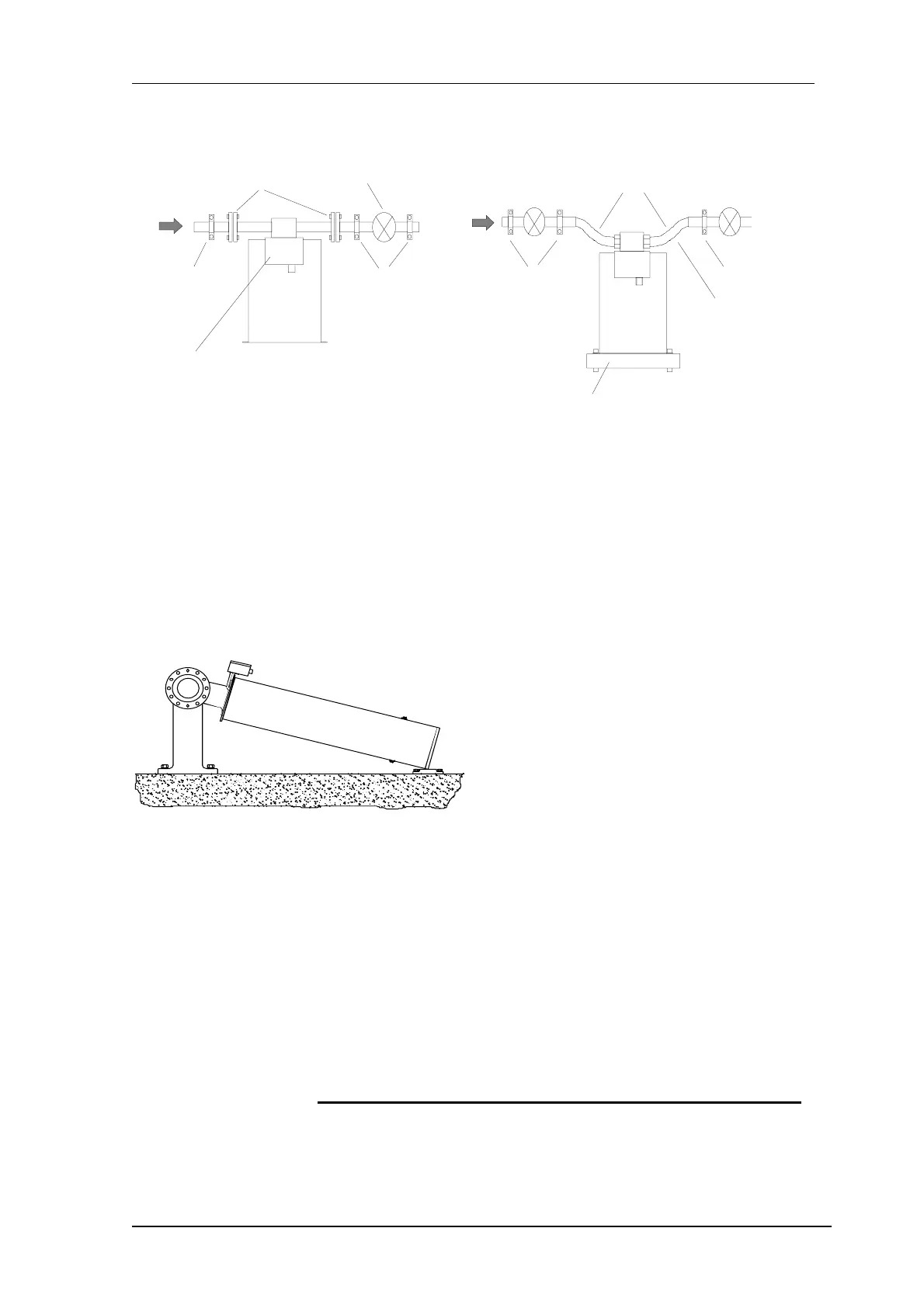

Flow

pipe support

pipe support

shut off valve

terminal box

process

connecton

sensor support

flexible hoses

pipe support

not recommended

for high pressure

as flexible hose

becomes stiff and

puts changing forces

onto the sensor

pipe support

The

sensor must be installed in a position with process connection on the upper side in order to

measure fluids (see sketch) and correspondingly in upside down position for gases (process connec-

tion on bottom and housing on top). The sensor must be completely filled with the medium. At the

same time gas bubbles must be completely removed from the device before the start of operations.

This can be achieved via appropriate flushing for a few minutes with a high throughput for example.

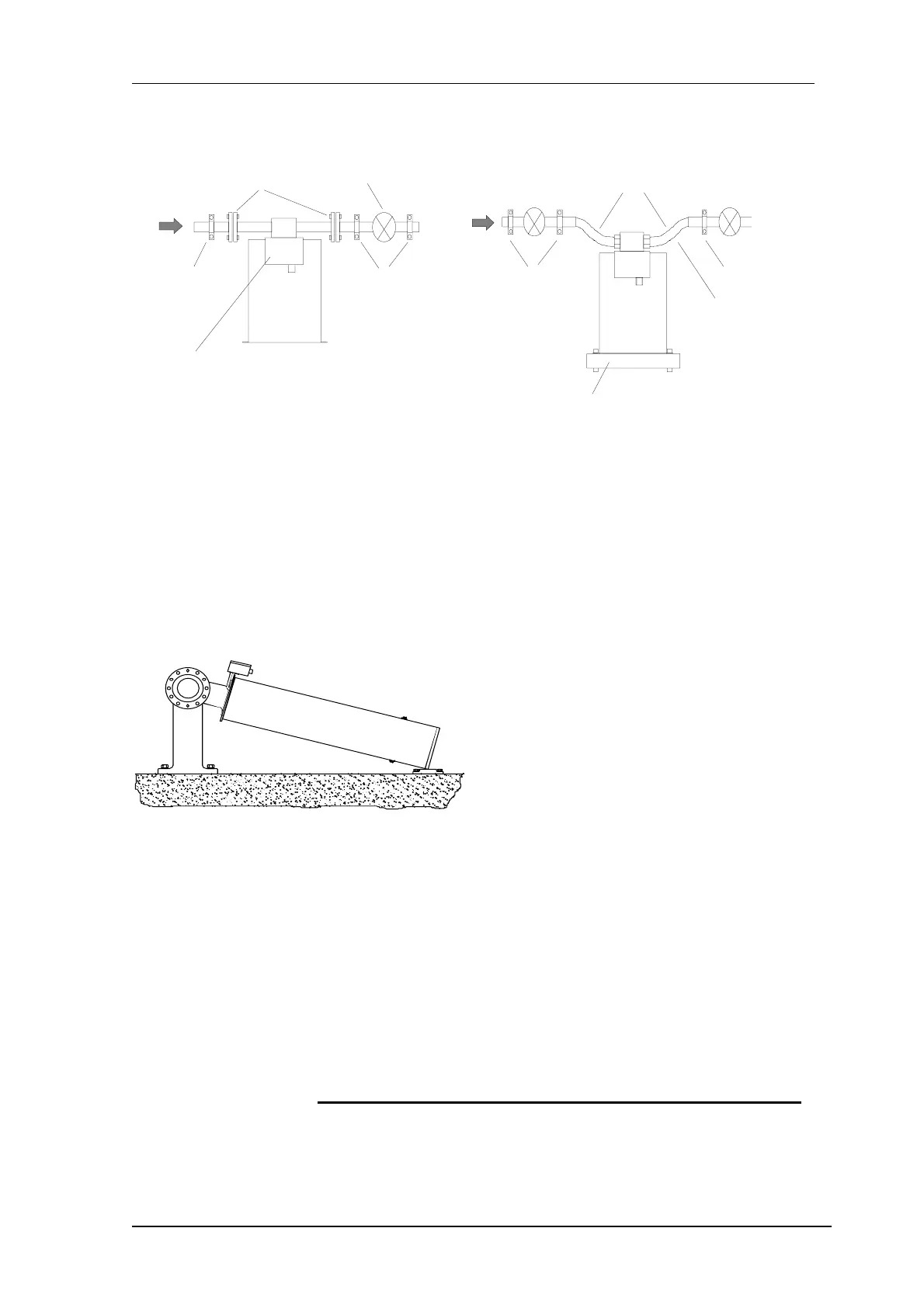

In the case of measuring minimal amounts of fluids (5 – 30 %), the sensor RHM 30, 40, 60, 80, 100,

and 160 can be installed in a nearly horisontal position (parallel to the floor).

For this mounting position, the housing flanges can

be used to secure it. In every instance, the sensor

and the piping must be secured in front of and

behind the sensor. It is preferable to use stiff

piping systems. Avoid extreme reducers, because

these can cause cavities within the measuring

tubes. Reducers should be installed several metres

from the measuring device when required.

In the case of the sensor sizes RHM 30 to 160 with parallel pipe loops, straight lengths of pipe are

foreseen if the medium is fed in from a very different axis than the one allowed by the pipe curve of

the sensor. We recommend a straight pipe with a length 3 – 5 times that of the pipe diameter for the

outflow and 5 – 10 times that of the pipe diameter for the inflow for the above mentioned sensor

designs, in order to prevent any significantly large differences in the flow speeds of the two measur-

ing pipes.

No valves or reducers should be installed between the pipe fixings and the sensor.

In the case of these equipment sizes, be sure to remove the transport safety fixtures before putting

into operation and to reseal the openings.

On bigger meters please remove the transportation fixation screws and reseal the housing

before start-up.

Loading...

Loading...