InstructionManualIM‐293

CUSTOMER'SINFORMATIONBOX

CONTENTSAREINDEPENDENTOFRIVERHAWKDOCUMENTCONTROL

215ClintonRoad

NewHartford,NY13413

Tel:+13157684855

Fax:+13157684941

Email:info@riverhawk.com

REV

373A4058

GEDRAWINGNUMBER

RevisionF

Page9of21

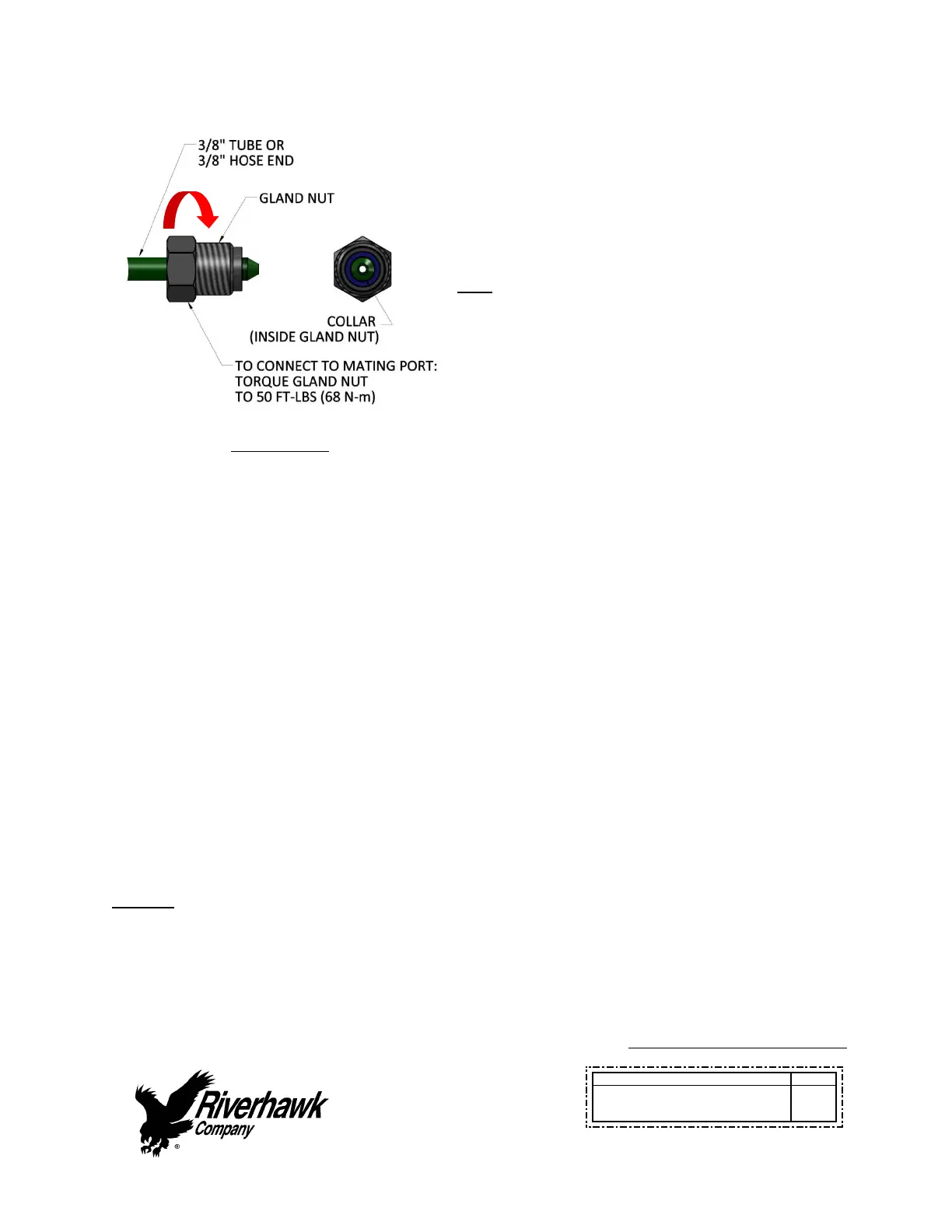

Illustration6

Slidetheglandnutdownoverthecollar.(See

Illustration6)Insertthe3/8”tubeor3/8”hose

endintotensionerorhydraulicpump.Whilefirmly

holdingthetubeorhoseendtostopitfrom

rotating,turntheglandnutclockwise(righthand

thread)andtorquetheglandnutto50FT‐LBS(68

N‐m).

Tips:

Makesureallpartsarecleanandfreefrom

debris.

Protecttheconeontheendofthe3/8”tube

or3/8”hoseendfromscratchesasthisisthe

sealingsurface.

Replaceredplasticcapswhenfinishedto

protectthethreadsandcone.

4.3CheckHydraulicPortinthePumpandTensioner

Beforeconnectingthehydraulichosetothepumportensioner,checkthehydraulicportfor

grit,dirt,andotherdebris.Cleanwithabrushand,ifnecessary,withavolatilesolventsuchas

acetone.Donotforcethedebrisdeeperintotheport.

4.4CheckHydraulicTensioner

Refertothehydraulictensionerinstructionmanualforinspectionprocedure.

5.0Operation

5.1ManualPumpOperation

Thefigures1and2attheendofthismanualdepictthelocationofthecomponentsusedto

operatethemanualpumpkits.

Step#1:Connectthepumptothetensionerwiththeappropriatehydraulichoseandopenthe

releaseknob.

WARNING

Checkthemaximumworkingpressuresofthehosesandtensionersconnectedtothepump.Do

notexceedthemaximumworkingpressureofthepump,hose,ortensioner.

Loading...

Loading...