6-3-7

RECOIL

STARTER

Standard configuration on Model EClOV, 17V.

Optional equipment for other models.

1)

Remove recoil starter from blower housing by unscrew

3

X

M6

bolts

(4

X

M6

bolts for Model EC17)

2)

Remove starting pulley from flywheel by loosing bolts clamped.

NOTE:

Unless it is necessary, do not disassemble recoil starter

as

special tools are required

for

reassembly.

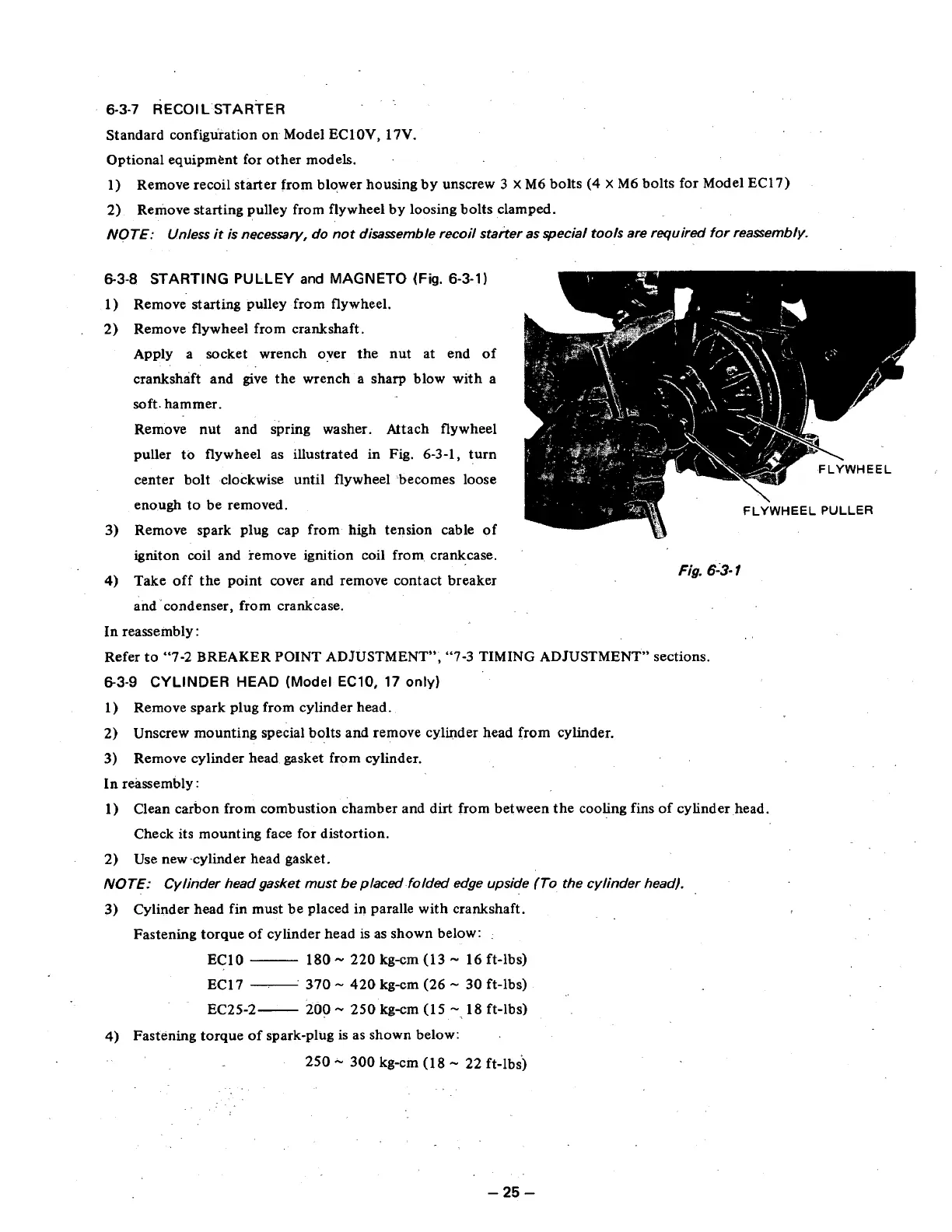

6-3-8

STARTING

PULLEY

and

MAGNETO

(Fig.

6-3-1)

Remove’ starting pulley from flywheel.

Remove flywheel from crankshaft.

Apply a socket wrench over the nut at end of

crankshaft and give the wrench a sharp blow with

a

soft.

hammer.

Remove nut and spring washer. Attach flywheel

puller to flywheel as illustrated in Fig. 6-3-1, turn

center bolt clockwise until flywheel -becomes loose

enough to be removed.

Remove spark plug cap from high tension cable

of

igniton coil and remove ignition coil from crankcase.

Take

off

the point cover and remove contact breaker

and” condenser, from crankcase.

In reassembly:

Fig.

6-3-

1

Refer to “7-2 BREAKER POINT ADJUSTMENT”, “7-3 TIMING ADJUSTMENT” sections.

6-3-9

CYLINDER HEAD

(Model

EC10,

17

only)

1)

Remove spark plug from cylinder head.

2)

Unscrew mounting special bolts and remove cylinder head from cylinder.

3)

Remove cylinder head gasket from cylinder.

In reassembly

:

1)

Clean carbon from combustion chamber and dirt from between the cooling fins of cylinder head.

Check its mounting face for distortion.

2)

Use

new -cylinder head gasket.

NOTE:

Cylinder head gasket must

be

placed folded

edge

upside

(To

the cylinder head).

3)

Cylinder head fin must be placed in paralle with crankshaft.

Fastening torque

of

cylinder head

is

as shown below:

EClO

-

180

-

220

kg-cm

(13

-

16

ft-lbs)

EC17

-

370

-

420

kg-cm (26

-

30

ft-lbs)

EC25-2-

200

-

250

kg-cm (15

-.

18

ft-lbs)

4)

Fastening torque of spark-plug is as shown below:

250

-

300 kg-cm

(18

-

22

ft-lbs)

L

..

I

-

25

-

Loading...

Loading...