3. Maintenance RO

i

400

ROCKINGER

Member of JOST-World

27

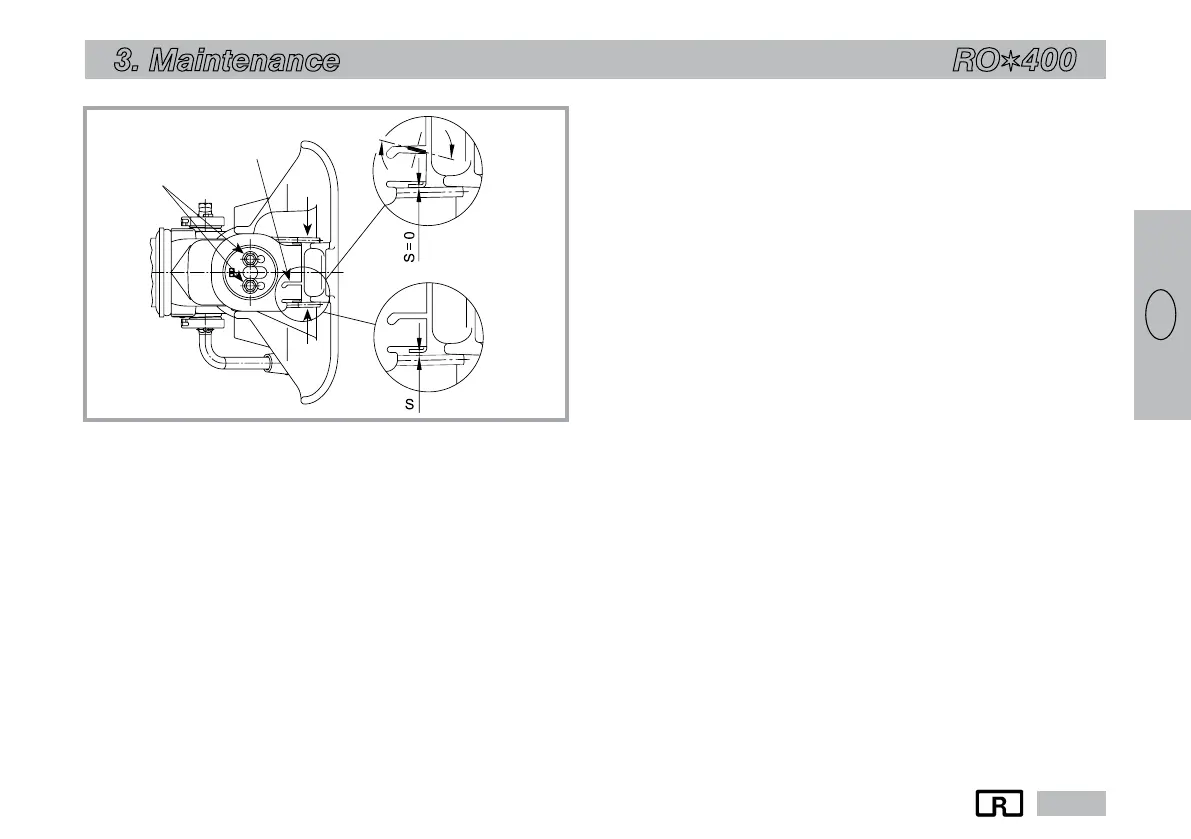

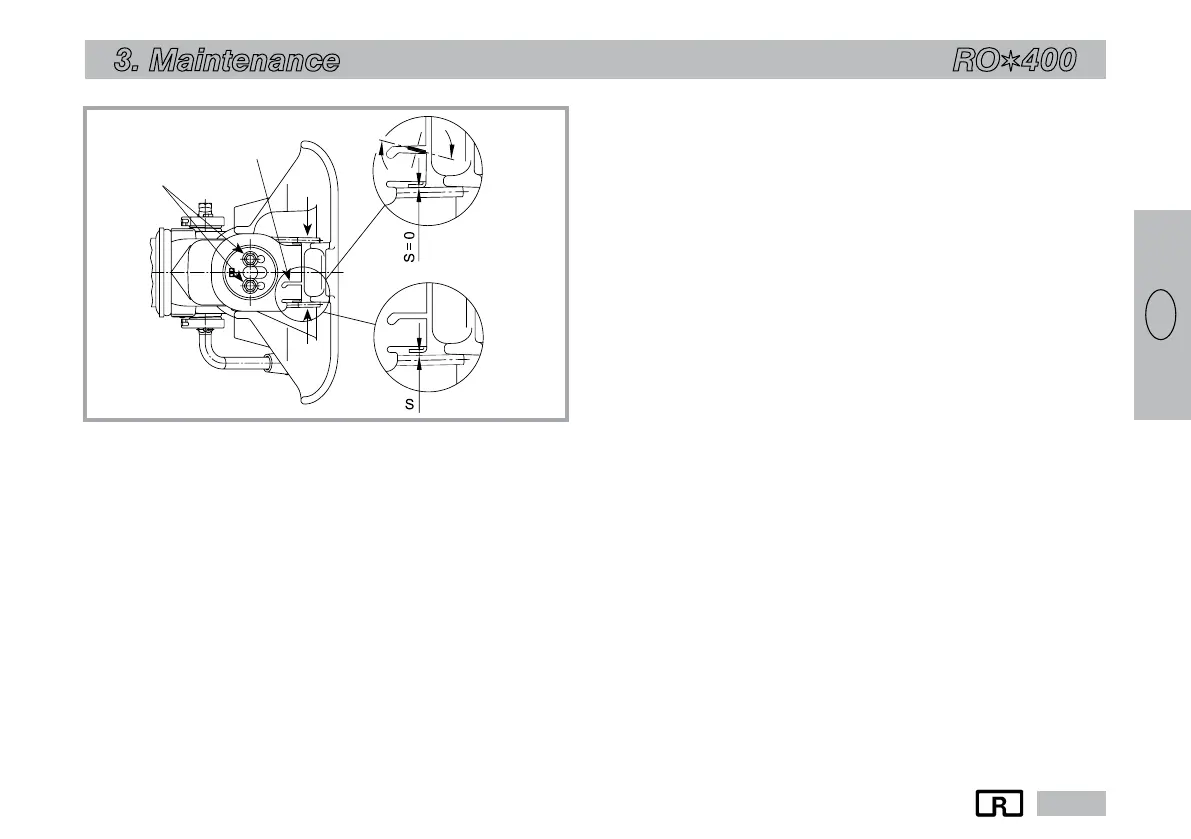

Check lock of the funnel:

Note: The funnel must be locked in its central position when coupling

is opened to be prepared for coupling on!

x Push the funnel sidewards

x Move handlever in locking direction (up)

x Release funnel

x The funnel must swing back in central position and be locked again

x If not, justify the central position by the lower unit as below.

Adjustment for technical release 1:

x Loosen screws (17) and bring the funnel into the central position:

x Open coupling: Funnel lock should be inserted

x Tighten screws (17) – Tightening torque 85 Nm.

x Both ends of torsion springs (R) must lie slack free (S) against the rib

of the funnel. Between the spring holder (H) and the lay-on points of

the torsion springs should also be no gap.

x In case there is gap you can close it very easilyby bending the spring

holder with a screwdriver (M) (see fig. (S = 0).

x Please, check the lock and movement of the funnel again

1)

Tightening torque for screws use a torque meter to fix according

to DIN ISO 6789, class A or B

GB

R

H

17

R

Fig. 11

Loading...

Loading...